12

n If installina decorative wood

panels on the door azd lower panel,

follow the “Changing the bin door and

lower panel” instructions.

13

n Turn on the water supplv

and check for leaks. Then turn on’the

electrical supply.

14

n Reattach the lower access

panel and air grille assembly.

15

H Check that all parts have

been installed and that no’steps were

skipped. Check that you have all the

tools you started with.

16

n Take a few minutes to read

the ‘How your ice maker works” and

“Things to remember” sections, Panel C,

and the Use and Care Guide to fully

understand your new ice maker.

Preparing the ice maker for use:

17

n Open the ice maker door.

Wash out the jnterior bin with a solution

of two tablespoons baking soda and

one quart water. Rinse the bin

thoroughly with water.

18

n Turn the ice maker control

knob to the “CLEAN” posttion. Check that

the pump motor is operating correctly.

Note: Only the pump motor operates in

the “CLEAN” setting.

Check the operation:

Before running your ice maker for tne

first time, note the following:

l

Water enters only during the harvest

cycle so the first harvest cycle will be

completed without water in the system.

l

Water will not enter the pump pan

until the freezing plate gets cold and

the ice maker begins a harvest cycle.

l

Once the ice maker has been operating

for a while, a normal harvest cycle takes

between 1 to 2 minutes to complete.

However, the initial run takes approxi-

mately three hours to produce ice.

l

The evaporator thermostat opens

when the evaporator reaches the

preset temperature (+lo”F to -3”F,

depending on the thickness of the

ice). The hot gas solenoid and the

water valve solenoid are energized at

this time and the pump motor and fan

motor will shut down. The motors will

remain off and the solenoids will

remain charged until the evaporator

reaches 38°F (+ 2°F) again.

l

Ice maker must run at least 24 hours

before adjusting the thickness setting.

19

n Turn the control knob to

“ON” position. Check that the

condenser fan is revolving.

Ice maker must run for three hours

before ice will form.

three hours. When water flows over the

freezing plate, check that it is flowing

evenly. If it is not, the ice maker is not

level and Step 10 should be repeated.

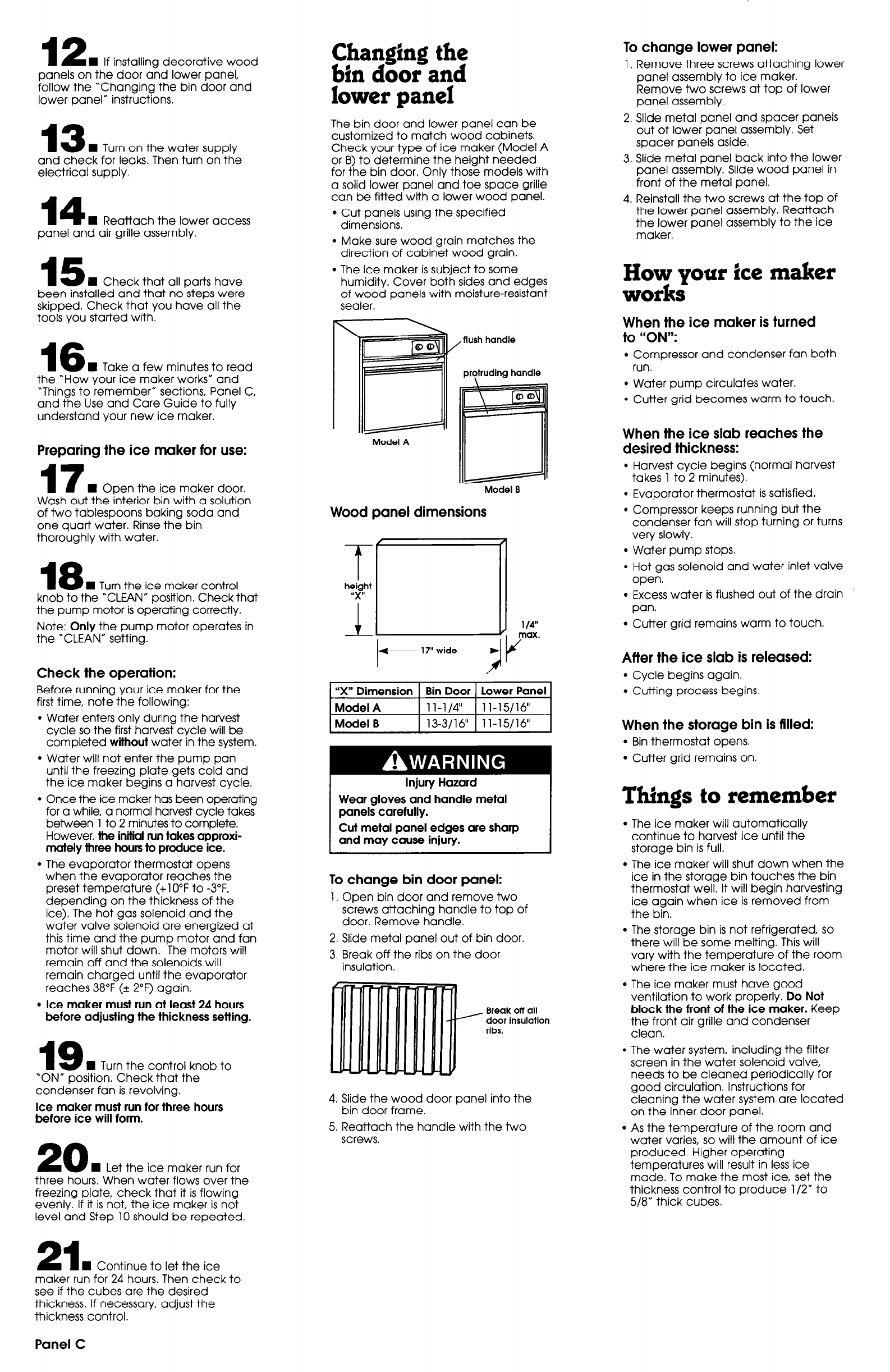

Changing the

bin door and

lower panel

The bin door and lower panel can be

customized to match wood cabinets.

Check your type of ice maker (Model A

or B) to determine the height needed

for the bin door. Only those models with

a solid lower panel and toe space grille

can be fitted with a lower wood panel.

l

Cut panels using the specified

dimensions.

l

Make sure wood grain matches the

direction of cabinet wood grain.

l

The ice maker is subject to some

humidity. Cover both sides and edges

of wood panels with moisture-resistant

sealer.

Wood panel dimensions

T

hei$ht

“X”

l/4”

“X” Dimension

Model A

Model B

Bin Door lower Panel

1 l-l /4” 1 l-15/16”

13-3116”

1 l-15/16”

Injury Hazard

Wear gloves and handle metal

panels carefully.

Cut metal panel edges are sharp

and may cause injury.

To change bin door panel:

1. Open bin door and remove two

screws attaching handle to top of

door. Remove handle.

2. Slide metal panel out of bin door.

3. Break off the ribs on the door

insulation.

0

Break off all

door insulation

ribs.

4. Slide the wood door panel into the

bin door frame.

5. Reattach the handle with the two

screws.

To change lower panel:

1. Remove three screws attaching lower

panel assembly to ice maker.

Remove two screws at top of lower

panel assembly.

2. Slide metal panel and spacer panels

out of lower panel assembly. Set

spacer panels aside.

3. Slide metal panel back into the lower

panel assembly. Slide wood panel in

front of the metal panel.

4. Reinstall the two screws at the top of

the lower panel assembly. Reattach

the lower panel assembly to the ice

maker.

How your ice maker

works

When the ice maker is turned

to “ON”:

l

Compressor and condenser fan both

run.

l

Water pump circulates water.

l

Cutter grid becomes warm to touch.

When the ice slab reaches the

desired thickness:

l

Harvest cycle begins (normal harvest

takes 1 to 2 minutes).

l

Evaporator thermostat is satisfied.

l

Compressor keeps running but the

condenser fan will stop turning or turns

very slowly.

l

Water pump stops.

l

Hot gas solenoid and water inlet valve

open.

l

Excess water is flushed out of the drain

pan.

l

Cutter grid remains warm to touch.

After the ice slab is released:

l

Cycle begins again.

l

Cutting process begins.

When the storage bin is filled:

l

Bin thermostat opens.

l

Cutter grid remains on.

Things to remember

l

The ice maker will automatically

continue to harvest ice until the

storage bin is full.

l

The ice maker will shut down when the

ice in the storage bin touches the bin

thermostat well. It will begin harvesting

ice again when ice is removed from

the bin.

l

The storage bin is not refrigerated, so

there will be some melting. This will

vary with the temperature of the room

where the ice maker is located.

l

The ice maker must have good

ventilation to work properly. Do Not

block the front of the ice maker. Keep

the front air grille and condenser

clean.

l

The water system, including the filter

screen in the water solenoid valve,

needs to be cleaned periodically for

good circulation. Instructions for

cleaning the water system are located

on the inner door panel.

l

As the temperature of the room and

water varies, so will the amount of ice

produced. Higher operating

temperatures will result in less ice

made. To make the most ice, set the

thickness control to produce l/2” to

5/8” thick cubes.

21

n Continue to let the ice

maker run for 24 hours. Then check to

see if the cubes are the desired

thickness. If necessary, adjust the

thickness control.

Panel C