143

10

10

COUNTERBALANCE SYSTEMS

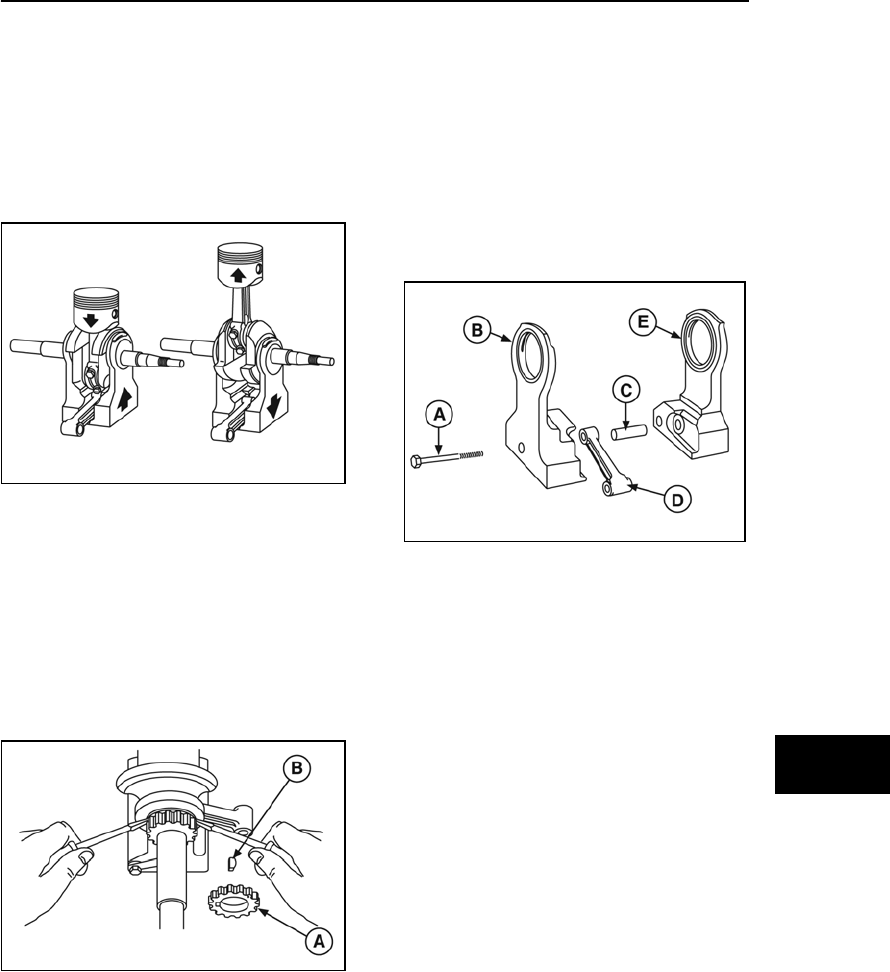

Two styles of counterbalance systems are used

on Vertical crankshaft engines.

Models 280000 and 310000 (built before July

2001) have the Synchro-Balance® system.

Models 280000 and 310000 built July 2001 and

later, and all models 210000 and 330000 have

the AVS® system. Both systems use a

counterweight that oscillates opposite the

direction of the piston, to reduce engine vibration

(Figure 25).

Figure 25

Synchro-Balance® System

Remove Counterbalance System

1. Remove blower housing, flywheel,

cylinder head, and sump. Discard gaskets.

2. Remove connecting rod and piston

assembly.

3. Remove crankshaft and counterweight

assembly.

Figure 26

Disassemble

1. Remove crankshaft gear (A, Figure 26).

NOTE: If gear is tight, pry it off using two

screwdrivers being careful not to damage gear.

2. Woodruff key (B) can be removed, if

required.

3. Remove screw (A, Figure 27) from

counterweight.

4. Remove PTO counterweight (B), dowel

pin (C), and link (D) from crankshaft.

5. Remove crankshaft from magneto

counterweight (E).

Figure 27

Inspect

1. Visually inspect counterweight bearings

for scoring or discoloration. If found,

replace both counterweights as a set.

2. Measure the counterweight bearing

diameters and compare to the values

shown in Section 12 - Engine

Specifications. If either bearing is worn

beyond the reject dimensions, replace

both counterweights as a set.

3. Measure the crankshaft eccentric

diameters and compare to the values

shown in Section 12 - Engine

Specifications.

4. If crankshaft eccentrics are worn, scored,

or discolored, replace the crankshaft.