32

6. Pull the auger shaft assembly straight out of cooling drum.

Inspect the shaft for abnormal wear.

7. From the front of dispenser, remove the seal and blue bushing

from cooling drum and discard them.

8. Clean seal and bushing surfaces of the cooling drum very

thoroughly.

9. Refer to FIG 1, and slip new blue bushing into cooling

drum.

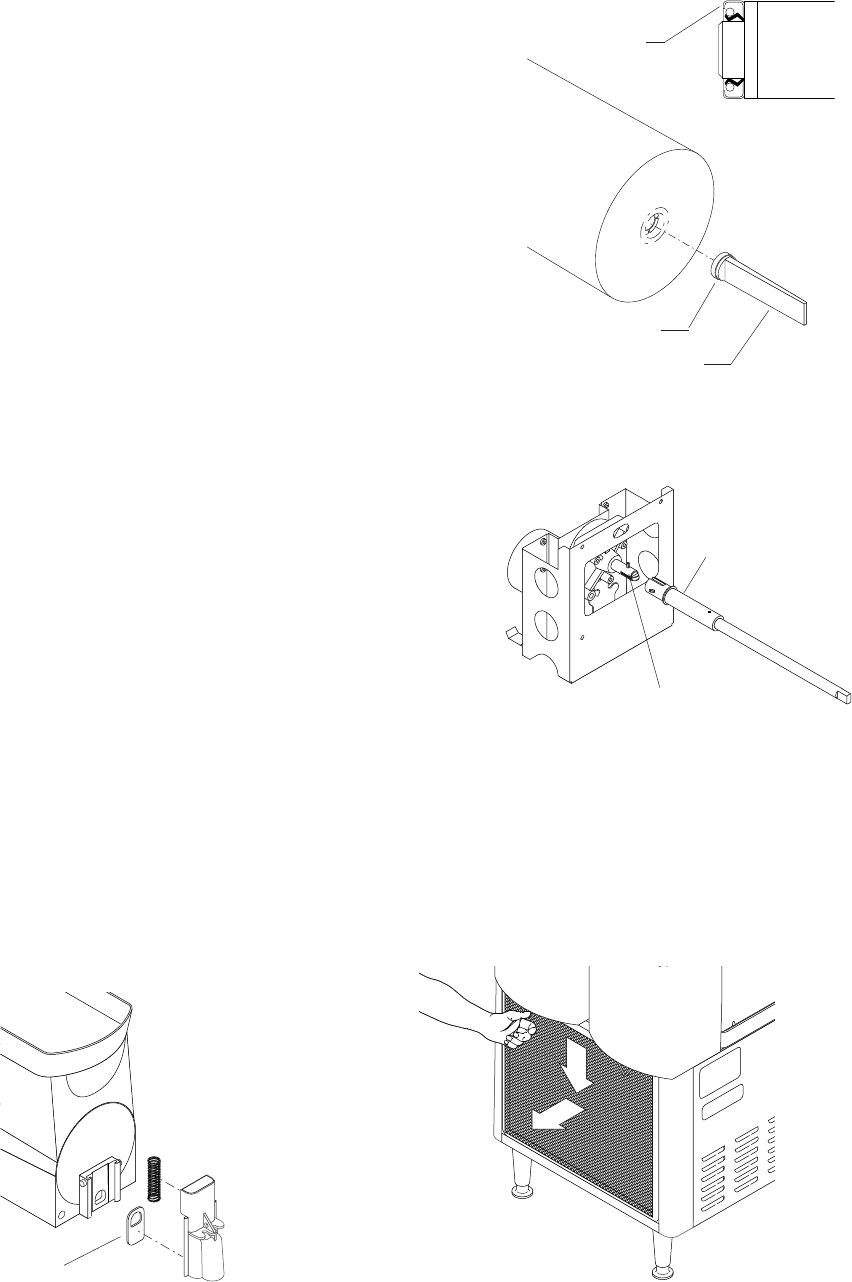

10. Place seal on insertion tool #28395.0000 as shown in FIG 2.

Make sure open face of seal is toward cooling drum.

11. Apply a small amount of food grade lubricant (Bunn

#M2568.1000) to inside diameter of seal. Push seal into bore

until it is firmly seated; remove tool.

12. Place a small amount of #29563.0000 “Krytox” lubricant

(provided in kit in a plastic cap) on the end of the motor shaft

(about 1

1

/

2

”) and a thin film in the groove. Install auger shaft

assembly onto the motor shaft. See FIG 3. Do not use too

much “Krytox” lubricant.

NOTE: This is the only place “Krytox” lubricant is used.

13. Assemble motor/shaft assembly as shown in FIG 3, then install

assembly into cooling drum. Make sure the pins do not hit

the sensor board and cooling drum seal is not dislodged as

the shaft passes through.

14. Secure motor and capacitor to the cooling drum mounting

bracket. Install rear motor cover.

15. Refer to the Installation and Operating Manual for hopper as-

sembly and installation procedures. Install new hopper/drum

seals and faucet seals included in the kit. See FIG 1 & 4.

16. Remove and clean condenser air filter. See FIG 5.

17. Refer to the Installation and Operating Manual, “Menu Function

Index”. Scroll to menu “PM Complete?” and answer “YES”

to reset the reminder message “PM Due”.

FIG 2

FIG 3

Lube about 1

1

/

2

” of shaft and in the

groove with #29563.0000 “Krytox”

Lubricant

Seal Insertion Tool

Open face of seal

away from tool

Cooling Drum Seal

Auger Shaft Assy

FIG 4

FIG 5

Faucet Seal

P1760

P2529

P2531

P2532

REQUIRED REGULAR MAINTENANCE (Continued)

32080.0001 022707