Page 23

SERVICE (cont.)

ELECTRONIC CONTROLS (cont.)

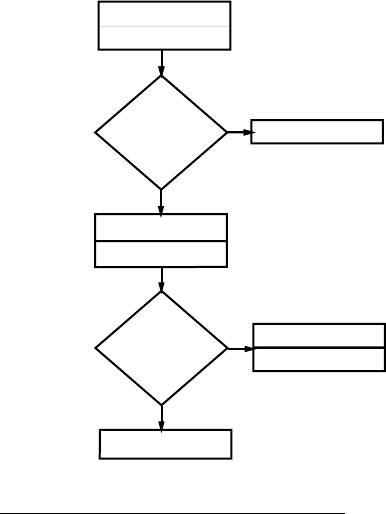

PROBLEM:

WATER BOILS

YES

NO

NO

NO

NO

REPLACE CONTROL

ASSEMBLY (1)

REPLACE TRIAC (17)

CHECK FOR SPLIT

TANK HEATER (5)

DRAIN CUP (4)

RETRY

LED (13)(15) ON

WHILE BOILING

DISCONNECT BLUE WIRE

FROM CONTROL BOARD PIN #7

RETRY

STILL BOILING

?

REPLACE CONTROL

ASSEMBLY (1)

the temperature sensor (8) and the electronic control

assembly (1).

NOTE - each temperature sensor is calibrated to an

electronic control assembly. Both components MUST

be replaced as a set.

7. Check the voltage across the tank heater (5) termi-

nals with a voltmeter. Connect the brewer to the

power source. The indication must be:

a.) 208 volts for three wire 120/208 volt models

and 240 volts for three wire 120/240 volt

models while the red indicator on the circuit

board is on or blinking.

b.) 200 to 240 volts ac for two wire 200 or 240 volt

models while the red indicator on the circuit

board is on or blinking.

8. Disconnect the brewer from the power source.

If voltage was present as described, the temperature

control of the system is operating properly.

If voltage was not present as described, contact Bunn-

O-Matic to order an electronic control assembly (1),

temperature sensor (8), and triac assembly (17) for

revaluation and proceed to #9.

9. Replace the electronic control assembly (1) and

temperature sensor (8).

NOTE - each electronic control assembly is calibrated

to a temperature sensor. Both components MUST be

replaced as a set.

10. Check the voltage across the tank heater terminals

(5) with a voltmeter. Connect the brewer to the

power source. The indication must be:

a.) 208 volts ac for three wire 120/208 volt mod-

els and 240 volt ac for three wire 120/240 volt

models while the red indicator on the circuit

board is on or blinking.

b.) 200 to 240 volts ac for two wire 200 or 240 volt

models while the red indicator on the circuit

board is on or blinking.

11. Disconnect the brewer from the power source.

If voltage was present as described, return the new

triac assembly (17) to Bunn-O-Matic for credit. The

temperature control of the system is operating prop-

erly.

If voltage was not present as described, reinstall your

existing electronic control assembly (1) and tempera-

ture sensor (8), and proceed to #12.

12. Replace the triac assembly (17).

P811

Temperature Control Test Procedure

1. Disconnect the brewer from the power source.

2. Check the voltage across terminals 3 & 4 of the

electronic control circuit board with a voltmeter.

Connect the brewer to the power source. The

indication must be:

a.) 208 volts ac for three wire 120/208 volt mod-

els and 240 volts ac for three wire 120/240 volt

models.

b.) 200 to 240 volts ac for two wire 200 or 240 volt

models.

3. Disconnect the brewer from the power source.

If voltage was present as described, proceed to #4.

If voltage was not present as described, refer to the

wiring diagrams and check the brewer wiring harness.

4. Connect the brewer to the power source and place

the tank heater switch in the “ON” position.

5. Observe the red indicator on the electronic control

circuit board (15).

6. Disconnect the brewer from the power source.

If the indicator was on or blinking, the temperature

sensor is operating properly, proceed to #7.

If the indicator was off, check the sensor connection

on the electronic control circuit board and/or replace

27124 050800