Page 27

SERVICE (cont.)

10225 031804

Location:

Viewing the brewer from the rear the sweetener

solenoid is mounted on the right side of the solenoid

mounting bracket which is secured to the trunk base.

Test Procedure:

1. Disconnect the brewer from the power source.

2. With a voltmeter, check the voltage across the

brown/white and white/violet wires on the sweet-

ener solenoid terminals when the ON/OFF switch

is in the “ON” position and the start switch is mo-

mentarily placed in the lower position. Connect

the brewer to the power source. After the approxi-

mate setting on the delay dial, the indication must

be:

a) 120 volts ac for two wire 120 volt models.

b) 240 volts ac for two wire 240 volt models.

c) 100 volts ac for two wire 100 volt models, re-

main for the approximate setting on the dilution

dial, and then return to its previous indication.

3. Disconnect the brewer from the power supply.

If voltage is present as described, proceed to #4.

If voltage is not present as described, refer to the

Wir-

ing Diagrams

and check the wiring harness.

4. Remove both wires from the coil and check for

continuity across the coil terminals. If continuity

is present as described, reconnect the brown/white

and white/violet wires and proceed to #5.

If continuity is not present as described, replace the

solenoid valve.

SWEETENER SOLENOID VALVE (OPTIONAL)

FIG. 20 SWEETENER SOLENOID VALVE

P1277.40

5. Check the solenoid valve for coil action. Connect

the brewer to the power source, place the ON/OFF

switch in the “ON” position and momentarily place

the start switch in the lower position and release.

Listen carefully after the approximate setting on

the delay dial in the vicinity of the solenoid valve

for a “clicking” sound as the coil magnet attracts

and after the approximate setting on the dilution

dial, repels the plunger.

6. Disconnect the brewer from the power source.

If the sound is heard as described and sweetener will

not pass through the solenoid valve, there may be a

blockage in the sweetener line before or after the so-

lenoid valve or, the solenoid valve may require inspec-

tion for wear, and removal of particles.

If the sound is not heard as described, replace the

solenoid valve.

Removal and Replacement:

1. Remove all wires from the solenoid valves.

2. Turn off the sweetener supply to the brewer.

3. Disconnect the water lines to and from the sole-

noid valves.

4. Remove the two #8-32 keps nuts holding the

mounting bracket to the trunk base.

5. Lift out the bracket.

6. Remove the two #10-32 slotted-head screws hold-

ing the solenoid valve to the mounting bracket.

7. Securely install the new solenoid valve to the

mounting bracket.

8. Attach the mounting bracket to the trunk base.

9. Securely fasten the sweetener and water lines to

and from the solenoid valves.

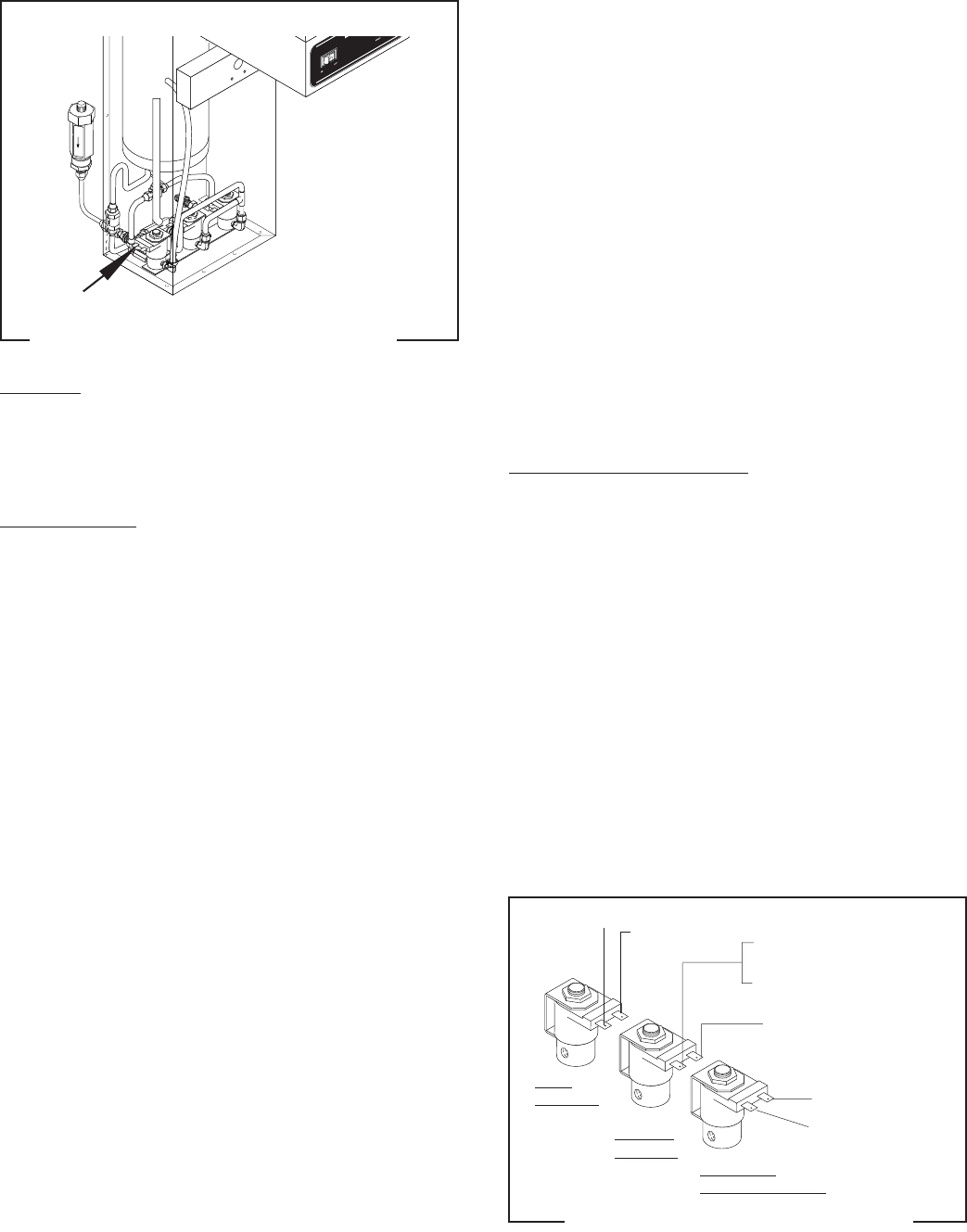

10. Refer to Fig. 21 when reconnecting the wires.

FIG.21 SOLENOID VALVE TERMINALS

P1278

BREW

SOLENOID

DILUTION

SOLENOID

SWEETENER

SOLENOID (Optional)

WHI/VIO to Dilution

Solenoid

WHI/GRN to

Brew Timer TL4

WHI/VIO to Brew Solenoid

WHI/VIO to Brew Timer TL1

WHI/BLU to Dilution

Timer TL4

WHI/VIO to Dilution

Solenoid

BRN/WHI to Selector

Switch