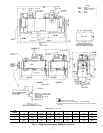

30HXA REFRIGERANT PIPING (See Fig. 7) — Take

care when running the refrigerant piping from the 30HXA

unit to the remote condenser(s) to avoid excessive pres-

sure drops. The pressure drop using R-134a refrigerant is

different than when using R-22 refrigerant. See Tables 2 and

3 for an example fora2F(1.1 C) pressure drop in saturated

temperature in the discharge (hot gas) line and liquid line,

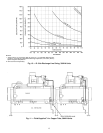

respectively. Refer to Fig. 9 and 10 for line sizing informa-

tion for the discharge and liquid lines for 30HXA (R-134a)

units.

Table 2 — Discharge Line 2 F (1.1 C) Drop in

Saturated Temperature Example

SATURATED

DISCHARGE

TEMP

PRESSURE

R-134a R-22

F C Psig kPa Psig kPa

126 52.2 187.5 1293 281.6 1942

124 51.1 182.0 1255 274.3 1891

⌬ PRESSURE 5.5 38 7.3 51

PRESSURE

RELIEF

DISCHARGE

LINE

LIQUID LINE

LIQUID LINE

ANGLE

VALVE

OIL

SEPARATOR

COOLER*

TO REMOTE

CONDENSER(S)

TO REMOTE

CONDENSER(S)

TO REMOTE

CONDENSER(S)

TO REMOTE

CONDENSER(S)

EXV

EXV

Fig.7—Typical 30HXA Refrigerant Piping to Remote Condenser

NOTES:

1. Piping shown is for general point-of-connection only and is not in-

tended to show details for a specific installation. Certified field wir-

ing anddimensional drawings areavailable uponrequest. The30HXA

units should be installed using certified drawings.

2. Refer to Carrier System Design Manual for details regarding pip-

ing techniques.

3. Piping and pressure relief devices are field supplied.

4. Vent pipes properly per local codes.

LEGEND

EXV — Electronic Expansion Valve

*See Fig. 6 for typical cooler piping.

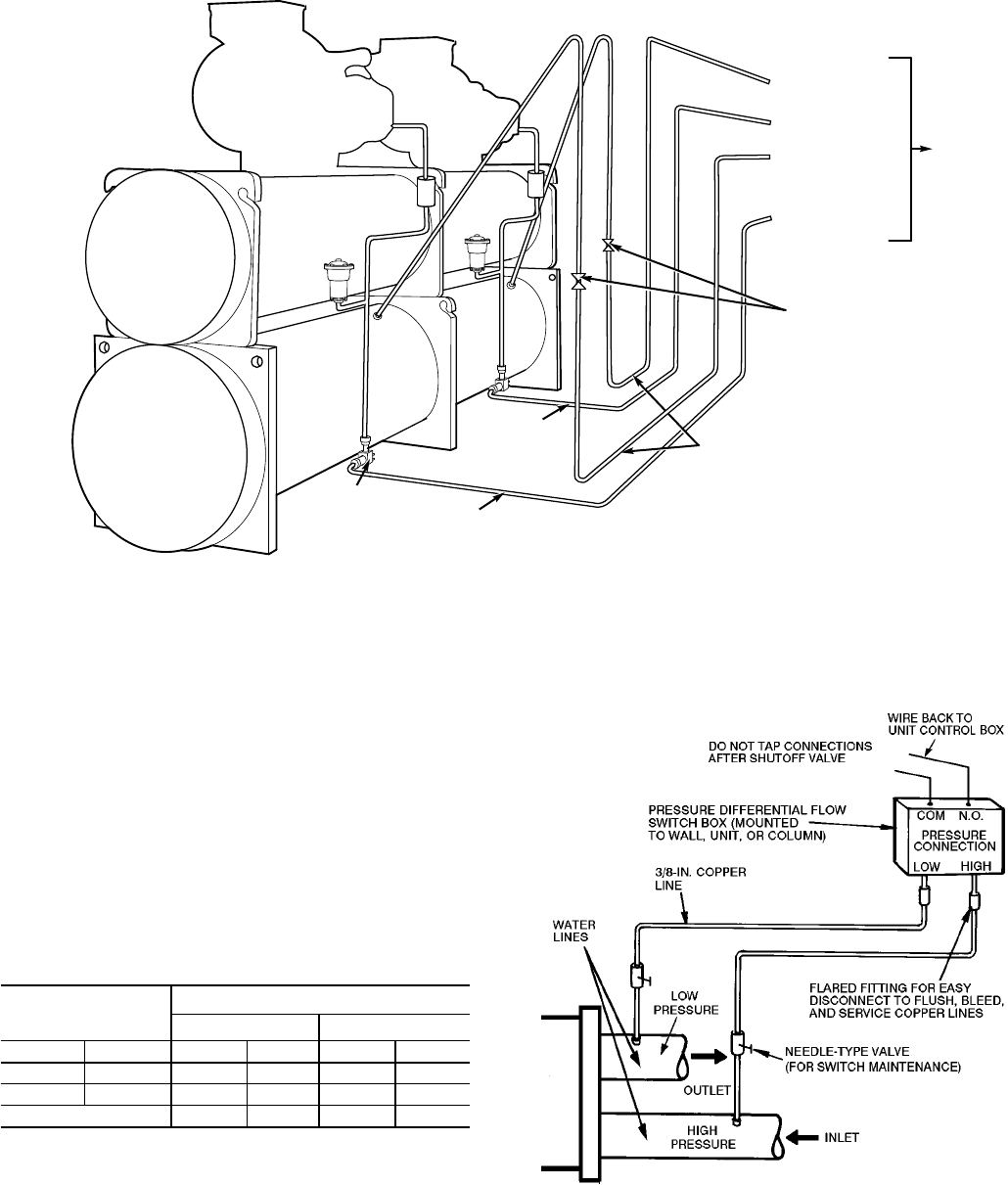

LEGEND

COM — Common

N.O. — Normally Open

Fig. 8 — Differential Flow Switch

11