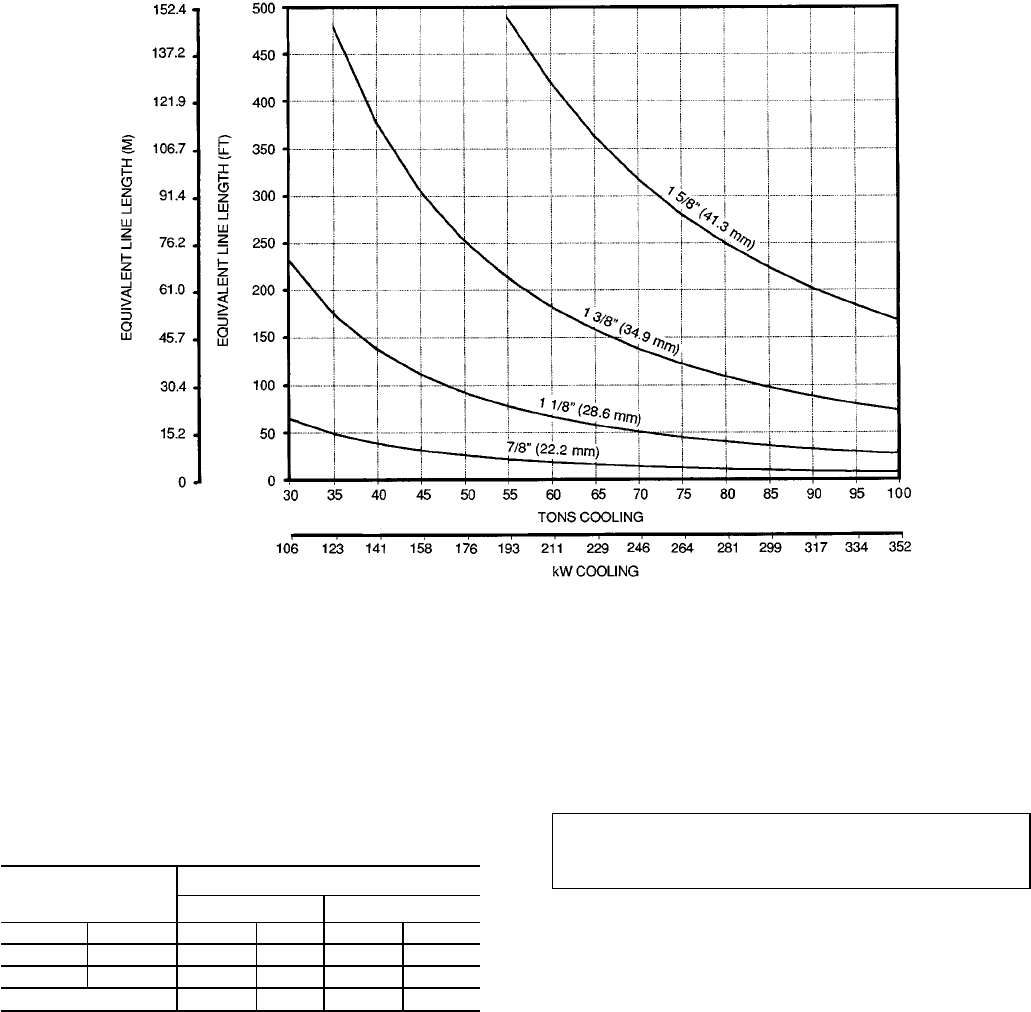

Table 3 — Liquid Line 2 F (1.1 C) Drop in

Saturated Temperature Example

SATURATED

LIQUID

TEMP

PRESSURE

R-134a R-22

F C Psig kPa Psig kPa

100 37.7 124.3 857 195.9 1351

98 36.7 120.1 828 190.2 1311

⌬ PRESSURE 4.2 29 5.7 40

Discharge lines should be looped above the compressors

to avoid having charge flowing back to the oil separator and

compressor during unit shutdown. Wrap back-pressure valve

when brazing discharge line to avoid damaging the valve.

It is recommended that field-supplied pressure relief valves

be installed in each discharge line. Most local codes require

that the relief valves be vented directly to the outdoors. The

vent must not be smaller than the relief valve outlet, and the

pressure setting should be 320 psig (2205 kPa).

Run a field-supplied

1

⁄

4

-in. (6.4 mm) copper line between

the back-pressure valve on the oil separator (bottom pres-

sure vessel) to the fitting on the refrigerant line entering the

economizer port of the compressor to measure oil pressure

differential. See Fig. 11. The back-pressure valve and the fit-

ting on the refrigerant line have a

1

⁄

4

-in. flare fitting for mak-

ing this connection. The flare nut is field supplied.

IMPORTANT: There is a Schrader-type fitting in each

of the two

1

⁄

4

-in. fittings. These Schrader-type fittings

MUST BE REMOVED before running the line.

The 30HXA units are shipped from the factory with a hold-

ing charge of R-134a. Before opening the refrigerant sys-

tem, relieve system pressure and recover system refrigerant

through the charging valve on the cooler.

30HXC CONDENSER CONNECTIONS — The inlet fluid

connection is always the lower of the 2 condenser con-

nections. It is recommended that a screen strainer with a

minimum of 20 mesh be installed ahead of the condenser

inlet to prevent debris from damaging the internal condenser

tubes.

The outlet water connection is the upper connection of

the 2 connections. The condenser has weld couplings to

connect field-supplied piping. Plan the piping arrangement

in accordance with good piping practices and so that the pip-

ing does not cross in front of the condenser head. Use flex-

ible connections on the condenser piping to reduce vibration

transmission. Offset the piping to permit condenser head re-

moval for maintenance purposes. Install pipe hangers where

needed. Make sure no weight or stress is placed on the water

nozzle.

NOTES:

1. Values are for a 2° F pressure drop at 125 F (51.7 C) saturated discharge tem-

perature, 120 F (48.9 C) saturated condensing temperature, and 105 F (40.6 C)

liquid refrigerant temperature.

2. Size each circuit separately.

Fig. 9 — R-134a Liquid Line Sizing, 30HXA Units

12