14

Models 750, 751, 754, 774, 794Important: To the Operator

Reset Button

On c ounter models, the reset button is located on the

side of the unit. On console models, the reset button

is located in the service panel. The reset protects the

beater motor from an overloadcondition. If anoverload

occurs, the reset mechanism will trip. To properly reset

the freezer, press the AUTO key to cancel the cycle.

T urn the power switch to the O FF position. Press the

reset button firmly.

Do not use metal objects to press the reset

button. Failure to follow this instruction may

result in electrocution.

T urn the power switch to the ON position. Press the

W ASH key and observe the freezer’s performance.

Open the side access panel. Make sure the beater

motor is turning the drive shaft in a clockwise d irection

(from the oper ator end) without binding.

If the beater motor isturning properly,press the WASH

keytocancelt he cycle. Pressthe AUTO key toresume

normal operation. If the freezer shuts down again,

contact a service technician. (For Models 754, 774,

and 794 press the AUTO key on both sides of the unit

to resume normal oper ation.)

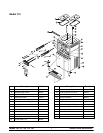

Air Tube

The air tube serves two purposes. One end of the tube

has a hole and the other end does not.

Figure 1

1. After priming the machine, lubricate the o-rings

on the air tube (the end with the hole) and

place it into the m ix inlet hole. E very time the

draw handle is raised, new m ix and air from the

hopper will flow down into the freezing c ylinder.

This will k eep the freezing cylinder pr operly

loaded and will maintain ov errun.

2. During long “No Sale” periods, remove the air

orifice. Lubricate the o-rings on the air tube (the

end without the hole), and place it into the

mix inlet hole. This will prevent any mix f rom

entering the freezing cylinder .

The air or ifice is used t o meter a certain amount

of air into the freezing cylinder . The air orifice

maintains overrun andallows enough mix toenter

the freezing cylinder after a draw.

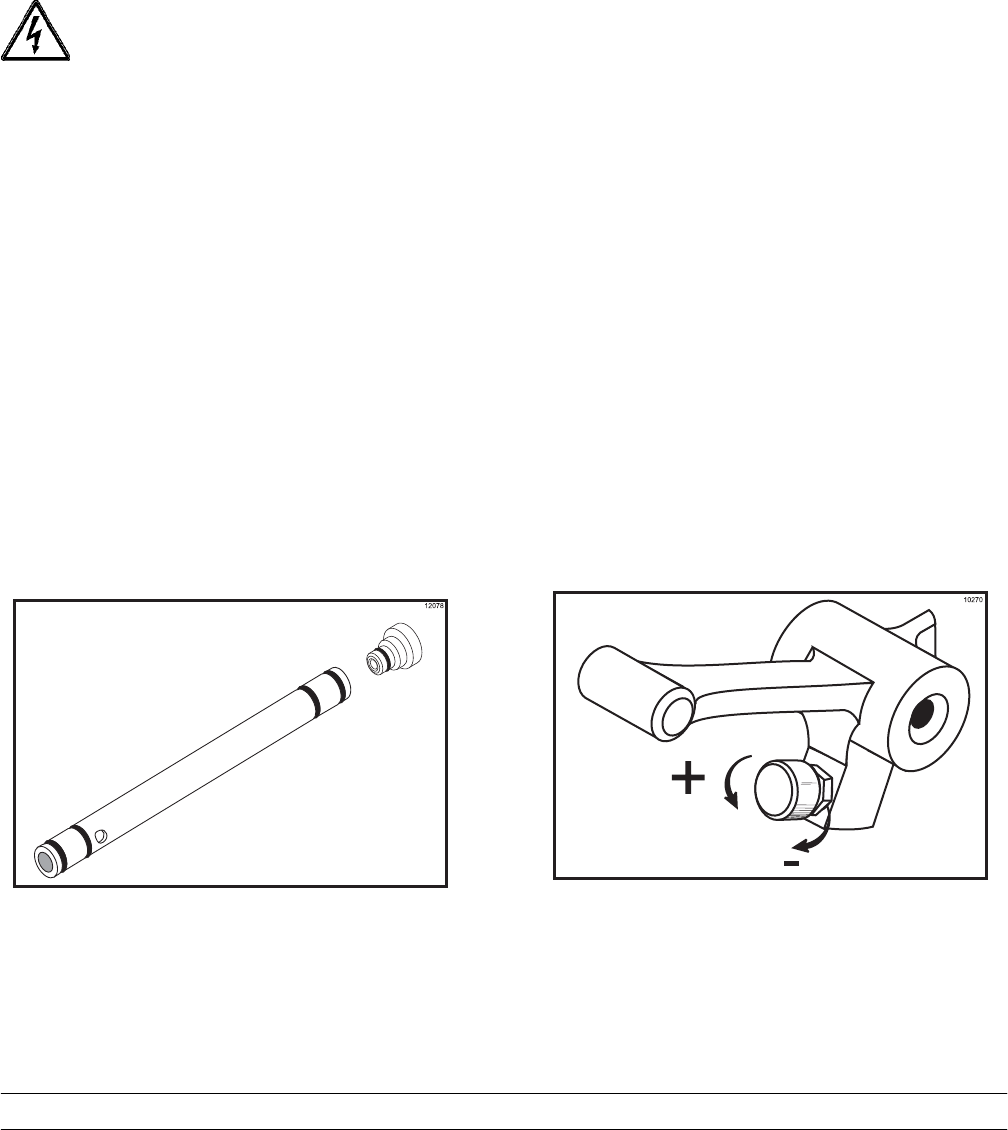

Adjustable Draw Handle

These units feature an adjustable draw handle to

provide the best portion control. The draw handle

should be adjusted to provide a flow rate of 5 to 7-1/2

oz. (148 to 222 ml) of product per 10 seconds. To

INCREASE the flow rate, turn the screw

COUNTERCLOCKWISE. T urn the screw

CLOCKWISE to DECREASE the flow rate. During

“Sanitizing” and “Rinsing”, the flow rate can be

increased by removing the pivot pin and placing the

restrictive bar on the TOP. When drawing product,

always place the restrictive bar on the bottom.

Figure 2

IMPORTANT: Once thedraw rate is set, tighten the

lock nut with a wrench.