Page 2.

MODEL SIG110LED

SUPPLIED ACCESSORIES

Part name Appearance Quantity

Grille

1

Tapping Screw

(ψ

4x25)

4

Screw

#8-32x1/4”

4

Duct connector 1

Duct Screw

(M4x12)

1

13”(318.5)

2

13”(318.5)

2

Inches (mm)

INSTALLATIONS

Proper insulation around the fan to minimize building heat loss

and gain.

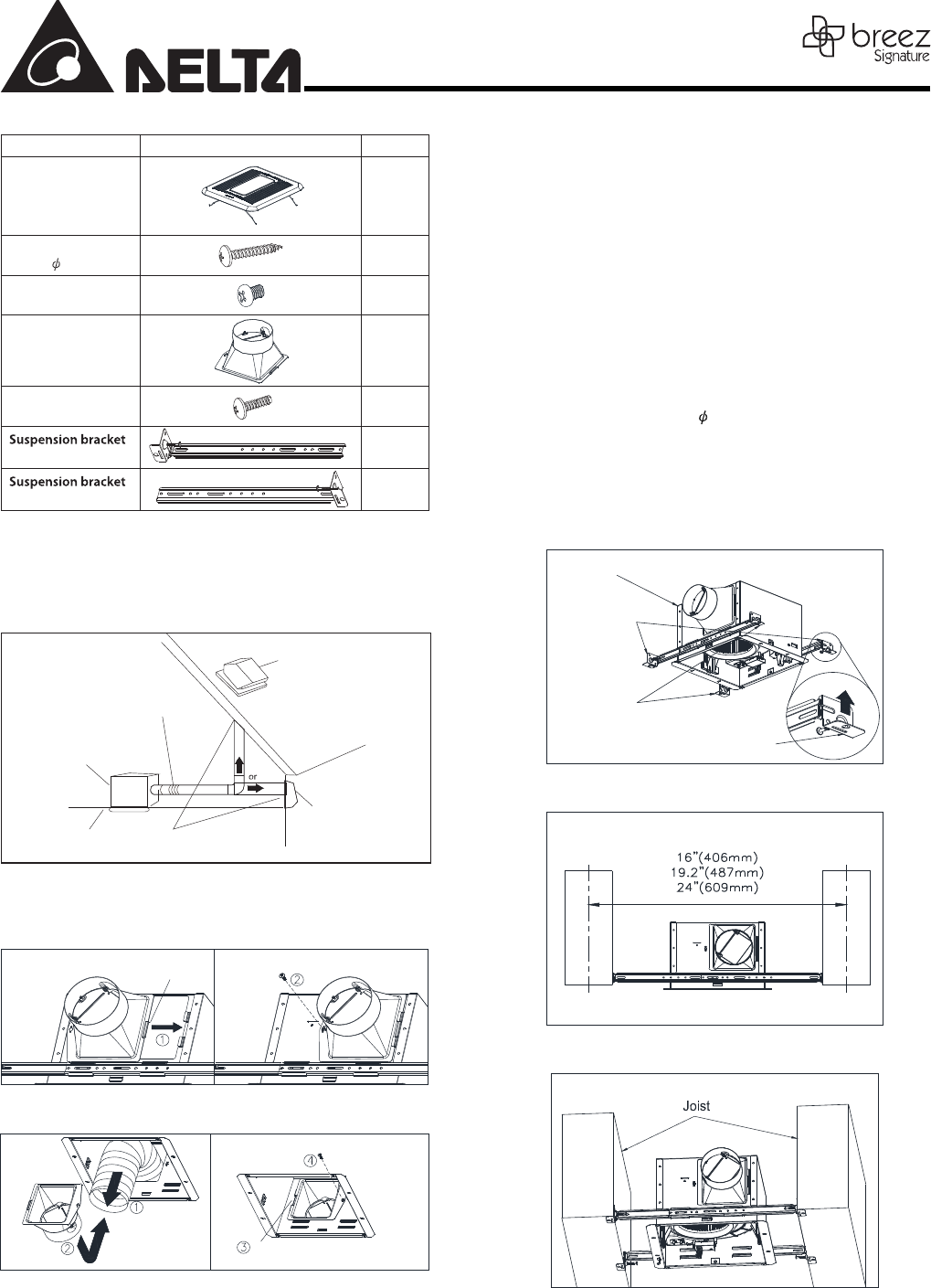

Attach Duct Connector

Option 1. Attach the duct connector from outside, and secure

using the duct screw (M4X12).

Insert tab into

slot in housing

Duct screw(M4X12)

from Parts Bag

Option 2. Attach the duct connector from the housing can inside,

and secure using the duct screw (M4X12).

Pull existing ductwork

into Housing

Insert tab into slot

in Housing

Duct screw(M4X12)

from Parts Bag

Note: Remove the tape from the damper and adaptor before

installation.

1. Using suspension brackets

1-1. Sliding suspension brackets are provided to allow for

positioning of the housing anyw here between joists up to a

span of 24”.

1-2. Insert the suspension brackets into the channels on the

housing. Make sure the tabs face up as shown. (Fig. C)

1-3. Extend the suspension brackets to t the width of the joists.

Hold the fan in place by wrapping the suspension bracket tabs

around the bottom of the joist. Make sure the fan body is level

and perpendicular to the joist. (Fig. D & E)

1-4. Ensure that the distance between the ceiling and fan body is

appropriate for mounting the grille.

1-5. Secure the suspension brackets to the joists with nails or by

using the tapping screws ( 4x25) through holes near nails.

1-6. Secure the suspension bracket to the fan body using the

screws (#8-32 x 1/4").

1-7. Follow steps 2 to 6 of the installation to complete the

installation work.

Suspension

Bracket II

Suspension

Bracket I

Body

Tab

Fig. C

Fig. D

Fig. E

ψ

Roof cap

(with built-in

damper)

Short piece of exible

duct helps alignment

and absorbs

sound

Wall cap

(with built-in

damper)

Caulk termination

to duct

Fan housing

Seal gap

around housing