Table 3

10

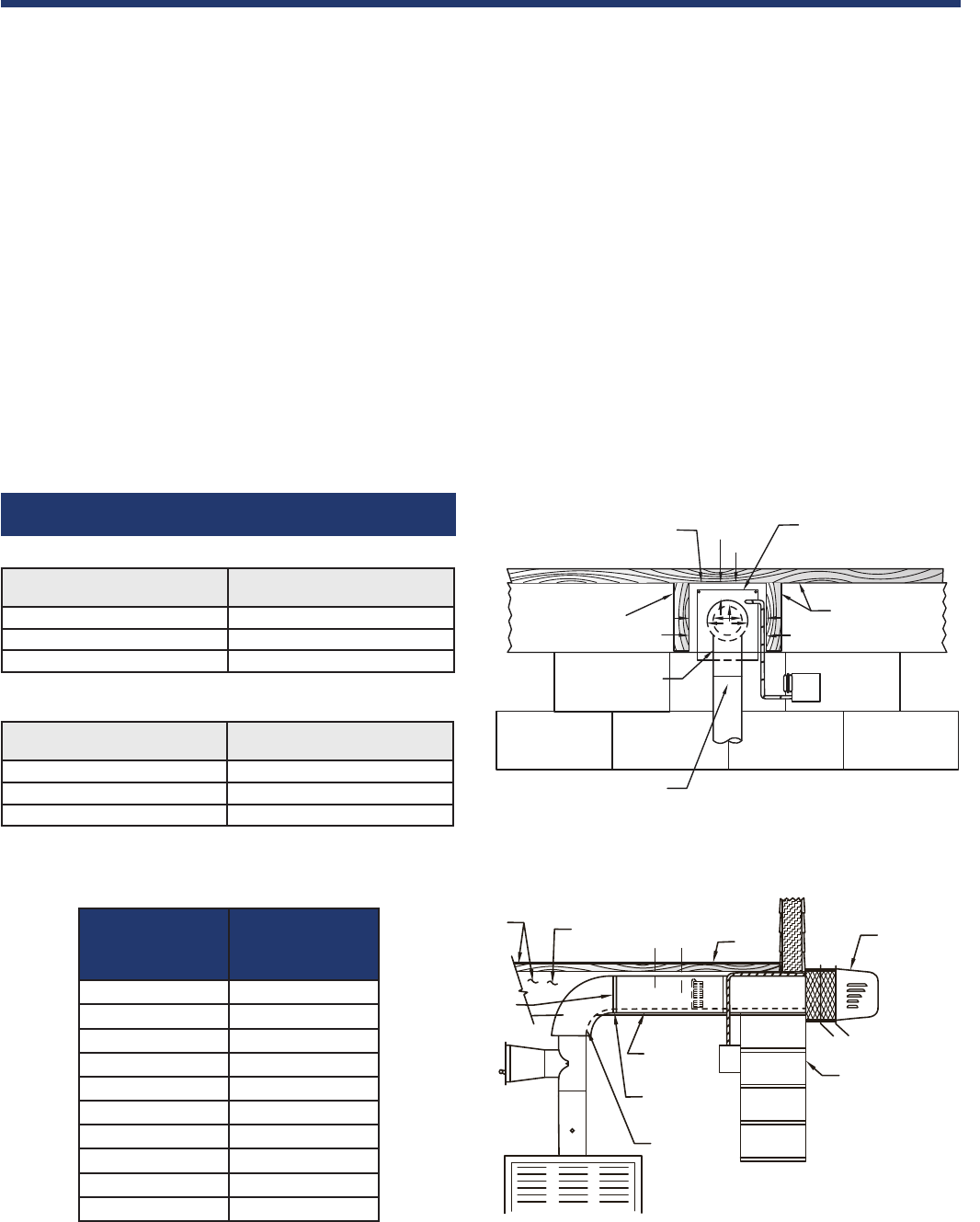

Clearance to Combustibles

If mounting the venting system near combustible

materials, refer to Diagram A for allowable installation

clearances. Clearances are based on an installation

using single wall galvanized steel vent pipe. If

manufactured double wall vent pipe is required or used

for the installation, clearance should be based on the

vent pipe’s rated clearance. Always check local code

requirements for code restrictions.

Routing of the vent system and clearances for the vent

pipe may be planned once the termination location is

determined. Route the vent pipe from the appliance to

the venter using as few elbows as possible. The

horizontal section of the vent pipe should have a slight

upward slope from the appliance to the venter. The vent

pipe size (diameter) can be smaller than a typical

chimney vented system and still overcome the higher

pressure losses because the power venter mechanically

creates the required draft or air flow to vent the system.

For estimating the minimum vent pipe diameter for an

oil system, multiply GPH by 140,000 BTU/GAL, then

divide by 12,600 BTU/sq. in. This will give the minimum

cross sectional area required. (See Table 3 for area to

diameter conversion.) For multiple equipment venting

systems, divide the total BTU/hr. input for all appliances

by 9,300 BTU/sq. in. This will give you the minimum

vent pipe diameter needed for the common breaching

of the vent system.

As a rule of thumb, size the vent pipe to the outlet

diameter of the heating equipment for a single

appliance venting system. For multiple appliance

venting systems, use the outlet diameter of the largest

unit and add 50%.

SQUARE HOLE

THROUGH WALL

COMBUSTIBLE

MATERIAL

METAL LINING FOR

550°F-400°F INPUT TEMP.

FLOOR JOIST

B-VENT

INPUT TEMP.

LOCATION

ELBOW

A

A

A

B

B

B

COMBUSTIBLE

MATERIAL

FLOOR JOIST

FLOOR

OUTER PIPE

EXTENSION

END PIPE COVER

SWG SERIES

POWER VENTER

BLOCK

FOUNDATION

FROM SWG UNIT

B-VENT or

L-VENT

ELBOW

INPUT TEMP.

LOCATION

A

B

Single Pipe System

Double Pipe System

Diagram A

Pipe Size

Nominal

Cross-Sectional Area

Sq.Inches

3" 7

4" 13

5" 20

6" 28

7" 38

8" 50

9" 64

10" 79

12" 113

14" 154

Allowable Inlet Temperature

Clearance (B)

400ºF or Less 3" min.

550ºF or Less 4" min.

550ºF or Less 3" min.*

Allowable Inlet Temperature

Clearance (A)

400ºF or Less .5" min.

550ºF or Less 1" min.

550ºF or Less .5" min.*

* With galvanized sheet metal liner or equivalent

7137FCHVentGuideOil_New:7137FCHVentGuideOil 5/8/08 10:45 AM Page 10