18

Leak-testing the cooktop

After the final gas connection has been made, turn the manual gas valve on and test the cooktop

and all connections in the gas supply piping for leaks with a soapy water solution. During leak-

testing, all the gas valves on the cooktop must be closed.

The presence of bubbles indicates a leak. If a leak is present, tighten or replace connections as

appropriate.

Important!

Do not use any naked flame to check for leaks.

Converting the cooktop to a different gas type

Important!

The conversion procedure must be carried out only by an authorized person.

This appliance is supplied with a set of injectors for the various types of gas.

Use the ‘Gas rate summary’ (following) to select the appropriate injector.

To convert from one gas type to another, you need to reset the gas pressure regulator, replace

the injectors, adjust the minimum burner setting, re-test for leaks and fill in/affix the gas

conversion labels.

1

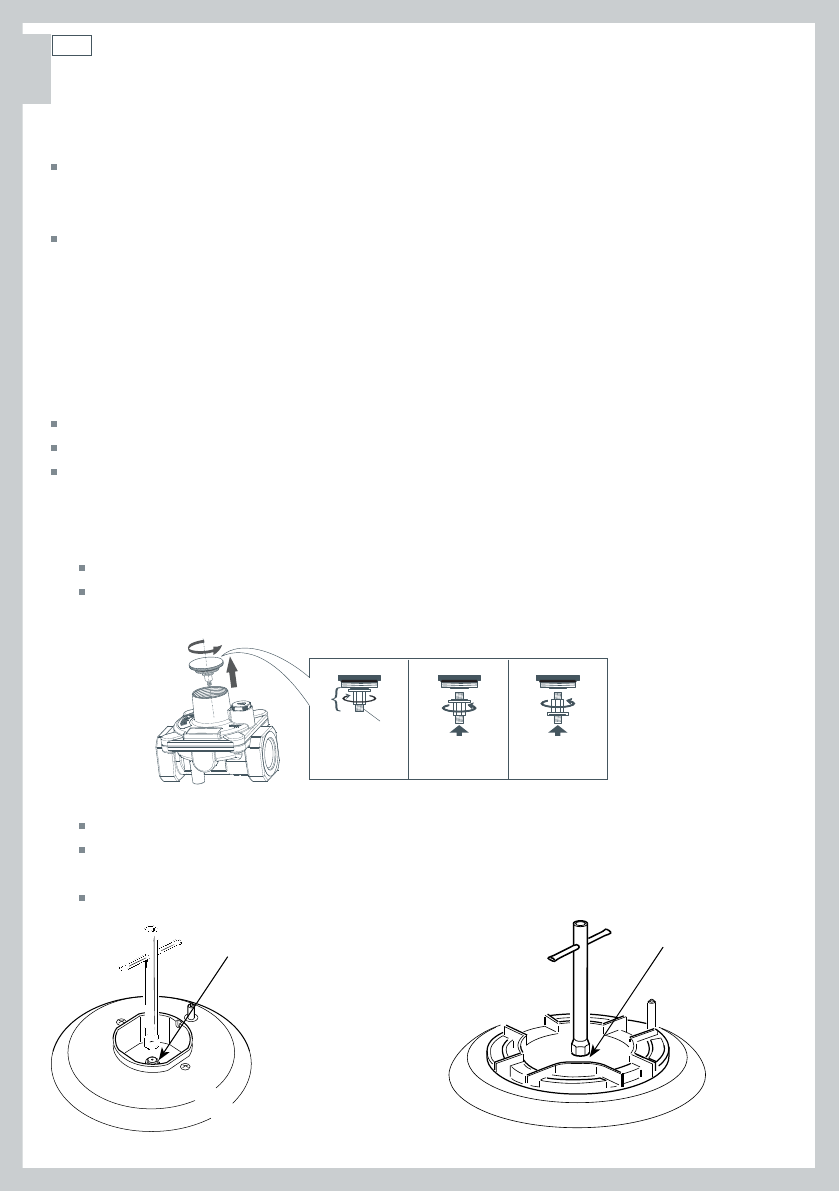

Reset the gas pressure regulator:

Unscrew the regulator cover and remove it.

Unscrew component “A”, reverse it and screw it back in according to the gas type you are

converting to (see Fig. 14 below).

2

Replace the injectors:

Remove the grates, burners and the control knobs.

Using a wrench, replace the injectors with those suitable for the kind of gas you are

converting the cooktop to. See the ‘Gas rate summary’ (following).

Note: the burners are designed so that regulation of primary air is not required.

Installation instructions

Fig. 15 Auxiliary, rapid and semi-rapid burners

Fig. 14 Resetting the gas pressure regulator

Fig. 16 Triple-ring wok burner (CG244 models only)

Injector

Injector

1

2

NATURAL GAS

REGULATION

LP/PROPANE

REGULATION

A

US CA