1

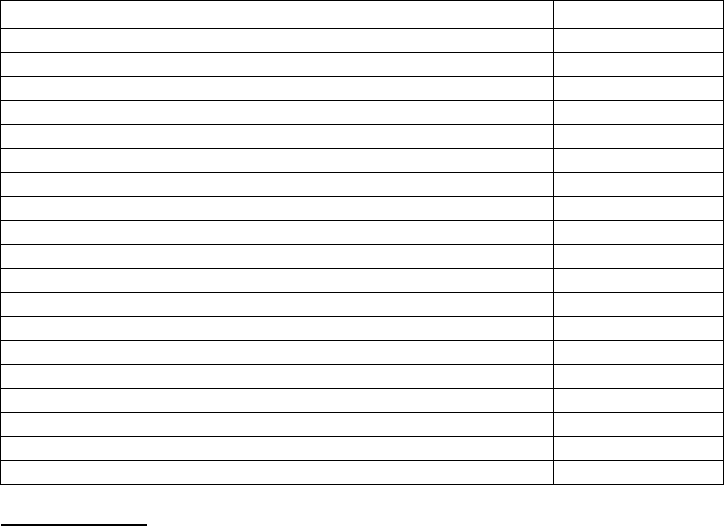

Contents Page

Introduction 1 to 2

Model Details 2

Controller Technical Detail 2

Parts List 2

Operating Instructions 3 to 6

Electrical Connections 7

Service Information 7 to 19

Diagnostics 8

Function Test 8

Passcode 8

Profiles 9

Parameter Access 9

Parameters 9 to 11

Parameter Definitions 11 to 18

Alarms and Warnings 18

Foot Print Test Operation 19

Probes 19

Technical Data 20 to 22

Wiring Diagrams 23 to

Introduction.

Cook Chill Operation.

Blast chilling is a process to reduce the temperature of cooked food by swiftly arresting the cooking process, locking in its

colour, flavour, texture and nutritional value. Department of health guidelines state that to safely blast chill food the

temperature must be reduced from +70°c to +3°c within 90 minutes.

Pre Chill

Pre chilling ensures the correct cabinet temperature in the unit before chilling commences therefore improving the chilling

performance.

Soft Chilling.

Soft chilling is the process of rapid but gentle chilling of food.

This cycle brings down the food temperature to +3°c in no more than 90 minutes without the air or food temperature going

below 0°c.

This prevents large ice crystals forming therefore maintaining the texture, consistency and appearance of food such as

vegetables, rice, pasta, custard and fruit with no dehydration or cell damage.

Hard Chilling.

Hard chilling is the process of general purpose chilling.

This cycle brings down the food temperature to +3°c in no more than 90 minutes and is ideal for chilling meat pies,

lasagne, pasta and individually portioned meals. The air temperature for this process goes down to -15°c for the first 70%

of the cycle, to extract the maximum amount of heat from the product quickly. The air temperature then increases to +3°c

for the final 30% of the time to reduce surface damage and ensure quality.

Hard Chill Max.

Hard chill max brings down the food temperature to +3°c in no more than 90 minutes and is used for chilling high density

or high fat content food such as meat joints, stews or packaged products.

The air temperature during the cycle is allowed to go down to -20°c.

After either a pre-designated time has elapsed or product temperature has been achieved, the air temperature is allowed

to rise to the ‘hold’ value with the temperature being maintained at this level indefinitely.

Surface Protection.

Removing the heat energy from food product as rapidly as possible by the combination of powerful refrigeration and

evaporator fans moving large volumes of cooled air can cause damage to the food product. The food product could have

a form of ‘Frost Burn’ caused by the fast moving air feeling cooler than the actual air temperature ‘Wind Chill Effect’. This

may lead to product discoloration, dehydration, localised freezing and spoilage of the food product.

Surface protection overcomes this by reducing the evaporation operation, and hence the air speed at pre-determined

stages in the cycle to ensure that this does not happen. This is a discreet function and happens automatically without any

intervention from the operator. To enable the surface protection; and determine at what stage it would be activated values

are set in the service operating parameters.

Longer Term Storage – ‘Hold’ Mode (Conservation)

Upon the completion of the blast chilling cycle the controller will automatically enter the ‘Hold’ mode. This will either be

because the selection set time has elapsed or the product core temperature has been achieved. When the hold period

commences an alarm will sound for a period denoted in the service operating parameters.