2

The controller will determine the temperature to be maintained during the hold phase based on the chilling cycle that has

been completed. If a soft or hard chill has taken place the controller will maintain an air temperature of 2°c.

The hold mode is principally intended as a temporary storage facility offering the operator flexibility until the product can

be unloaded into a longer term storage units at the correct storage temperature. On occasion this hold period may

become extended to operate overnight or to provide emergency refrigeration backup. In such instances defrosting would

automatically occur as necessary.

Model Details.

The RBC 20-60 is capable of blast chilling 60kg of product from +70°c to +3°c in 90 minutes with entry temperature up to

90°c

The cabinet is compatible with the Rational 20 rack GN 1/1 201 trolley.

Refrigerant used is R404A.

The RBC20-60 has two separate refrigeration systems comprising, two condensing units, a twin circuit condenser and a

twin circuit evaporator. (See pages 20 and 21 for assembly details and page 22 for schematic dual circuit refrigeration

layout).

The RBC20-60R has the same refrigeration systems but the condensing units are remotely sited.

Refrigerant control is by expansion valve to control the correct amount of refrigerant required to meet the demand of the

evaporator. (See page 21 for assembly detail).

The parameter ‘Capacity Enable’ is set to ‘ON’ to allow for both condensing units to be running during the chill cycle

therefore maximising the heat extraction from the product. During the ‘HOLD’ mode with the ‘Capacity Enable’ set to ‘ON’

one compressor will control the temperature throughout unless the temperature exceeds the capacity control limit.

A 1½” BSP drain outlet is fitted in to the base of the cabinet for connection to external drain.

The cabinet is delivered with the legs secured to the base of the cabinet.

Controller Technical Detail

The FCC controller is a three-piece unit made up of the Front Display and Dial Shaft Encoder, Mother Board plus

Evaporator, Food and Air temperature probes. The front display PCB and the CPU/ Switching PCB unit are

interconnected by a ribbon cable. The membrane attached to the front provides an IP rating of IP54 providing a scratch

free wipe clean finish.

The control dial is the method by which the controller is accessed for all requirements. It has three planes of movement,

clockwise, anticlockwise and inwards.

The control dial allows the operator/ engineer to move forward and backwards through various menu selections shown on

the display, and enter a desired programme. The control system will then respond appropriately either commencing the

operating cycle or allowing further configuration.

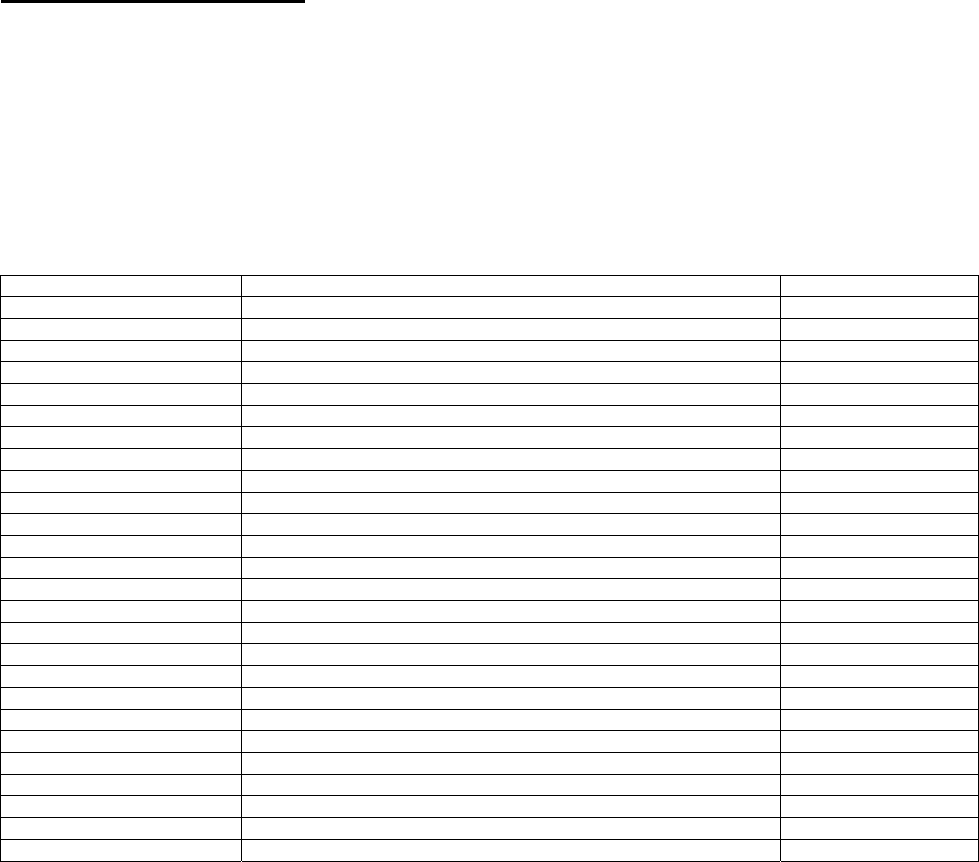

Part numbers

Item Description Part Number

Controller Mother Board 00-555395

Controller Shaft Encoder 00-555396

Controller LCD Display 00-555394

Air Probe P1 NTC type. 2.5m 00-555397

Evaporator Probe P2 NTC type. 2.5m 00-555397

Food Probe 5M Length 00-555663

Compressor x 2 TAJ4519ZH T 400/50 00-555885

Condenser Coil BC6013/122 01-257300-01

Condenser Fan Assembly S4E300-BP26-30 00-555886

Sight Glass 3/8" 15483015

Drier 00-555388

Solenoid Valve EVR6 32F5219+0 15451215

Liquid Receiver 00-555579

LP Switch 2.5 Bar 0.5 Bar Diff 00-555387

HP Switch 28 Bar – 3 Bar Diff 00-555386

High Pressure Thermostat KP5 Auto Re-set (set at 18 BAR with a 3 BAR diff.) 15452109

Evaporator Coil BC6013/121 01-256400-01

Expansion Valve Valve Body TES2-NL68Z34300/68 15450386

Orifice NO 02 68-2092/68-2072 15451104

Expansion Valve Solder Adaptor 68-2 15450910

Evaporator Fan Motor W4E420-CP02-66788-4-7320 00-555375

hinge Edgemount 00-555880

Door Gasket 1406x546MM 01-256387-01

Door Switch Circular (Reed Type) 00-555829

Door Switch Magnet Circular 00-555828

Door Handle Edgemount Latch Kit 00-555881