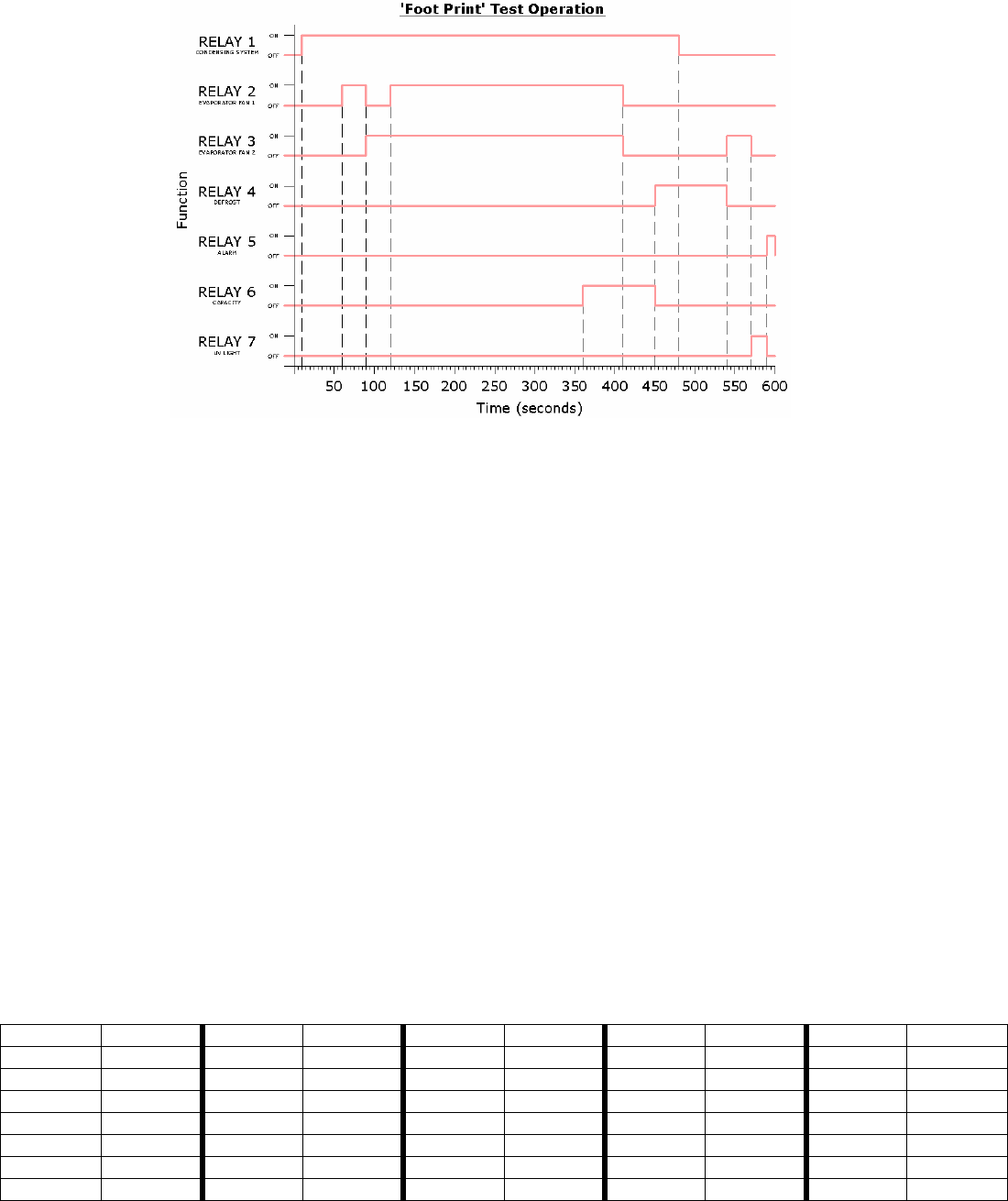

Foot Print Test operation

The foot print test is a method of checking the operation of the process in a reduced time period

The foot print test takes ten minutes.

The first ten seconds are used for the display test, after that the relays are energised in a simple operating pattern to

ensure each are energised. During the final ten seconds the alarm is sounded to indicate the end of the test.

The graph below shows how the relays are energised relating to time.

The air, coil and food temperature probes are disregarded (the only exception is an over temperature alarm).

Operation Summary

All relays commence Footprint test in the de-energised state.

• Relay 1 is energised after 10 seconds from start of test for 470 seconds (de-energises 480 seconds from start).

• Relay 2 is energised after 60 seconds from start of test for 30 seconds (de-energises 90 seconds from start).

• Relay 2 is energised again after 120 seconds from start of test for 300 seconds (de-energises 420 seconds from start).

• Relay 3 is energised after 90 seconds from start of test for 330 seconds (de-energises 420 seconds from start).

• Relay 3 is energised after 540 seconds from start of test for 30 seconds (de-energises 570 seconds from start).

• Relay 4 is energised after 450 seconds from start of test for 90 seconds (de-energises 540 seconds from start).

• Relay 5 is energised after 590 seconds from start of test for 10 seconds (de-energises 600 seconds from start).

• Relay 6 is energised after 360 seconds from start of test for 90 seconds (de-energises 450 seconds from start).

• Relay 7 is energised after 570 seconds from start of test for 20 seconds (de-energises 590 seconds from start).

All relays are de-energised on completion of the test.

At any point during the test pressing and holding the dial for 2 seconds can stop it. The test will be terminated and the

display will revert to the last run cycle. Upon normal completion of the test the display will revert to the last run cycle (not

the service parameters).

Probes

Air and Evaporator Probes

The air and evaporator probes are the same and are identified as T1 Air Probe and T2 Evaporator Probe. These are the

thermistor type and are fully enclosed to make it completely waterproof and resilient to temperature variation within the

limits of rapid cycling. The probe is capable of measuring temperature in excess of -30°C and 50°C with 1°K accuracy at

1°C and no more than 2°K at the upper and lower temperature ranges.

Food Probe

The food probe is inserted directly into the product that is being chilled to measure the core temperature. The resistance

values are the same as for the air and evaporator probes.

Probe temperature resistance values

°C K ohm °C K ohm °C K ohm °C K ohm °C K ohm

-40 44.657 -5 7.198 30 1.651 65 0.497 100 0.189

-35 33.505 0 5.716 35 1.371 70 0.426 105 0.166

-30 25.388 5 4.571 40 1.143 75 0.367 110 0.142

-25 19.402 10 3.682 45 0.958 80 0.318 115 0.125

-20 14.961 15 2.987 50 0.807 85 0.276 120 0.111

-15 11.644 20 2.437 55 0.683 90 0.24 125 0.099

-10 8.133 25 2 60 0.582 95 0.21

19