1-18

Improper Temperature Control

Temperature control—including that for the melt cycle—is a function of several interrelated components,

each of which must operate correctly. The principal component is the thermostat (in units equipped

with thermostat controls) or the temperature probe (in fryers equipped with other types of controllers).

Depending upon the specifi c confi guration of the fryer, it may also include an interface board and

controller. Problems with improper temperature control can be categorized into those issues concerning

melt cycle malfunctions and those concerning a failure to control at setpoint.

Melt Cycle

In fryers equipped with thermostat controls, the melt cycle is controlled with a solid state melt cycle

board and a melt cycle switch on the control panel. In all cases, replace the defective component.

In fryers equipped with other types of controllers, the problem may originate in the controller,

the temperature probe, or a malfunctioning heat relay on the interface board. For problem isolation

techniques, refer to the troubleshooting guides, Troubleshooting the Thermostat and Troubleshooting the

Temperature Probe, in Section 1.7, Troubleshooting.

Failure to Control at Setpoint

In fryers equipped with thermostat controls, the problem will

be in the thermostat. Refer to Section 1.3.5 for instructions on

calibrating the thermostat. Possible causes are that

• the thermostat is out of calibration,

• the knob or fl exible shaft is loose on the thermostat shaft,

• a thermostat wire is disconnected or broken, or

• the thermostat is defective.

Refer to Section 1.3.5 for instructions on calibrating the

thermostat. In fryers equipped with other types of controls, the

problem may originate in the temperature probe or probe circuit,

the interface board, or the controller. Refer to Troubleshooting the Temperature Probe, Section 1.7.4.,

for problem isolation techniques.

Gas Valve Malfunction

Occasionally, a gas valve may malfunction. Use Section 1.7.2, Troubleshooting the Gas Valve, to

determine if the valve has failed.

Computer Malfunction

Before diagnosing problems related to a computer controller, it is important to understand the use and

signifi cance of sensitivity and recovery.

Sensitivity and Recovery

Sensitivity—or “stretch time”—is a programmable feature, patented by Frymaster, which increases or

decreases the cook time countdown based on variation in the oil temperature from the setpoint. The

Up for reverse

Sediment

Particle

Oil Flow

Down for forward

Sediment

Particle

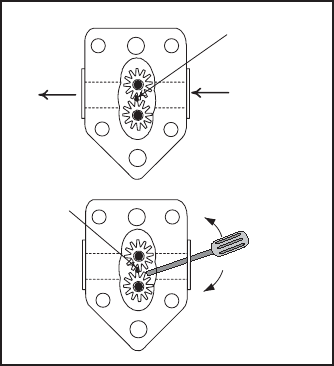

Removing debris or shortening from

a seized pump.