1-4

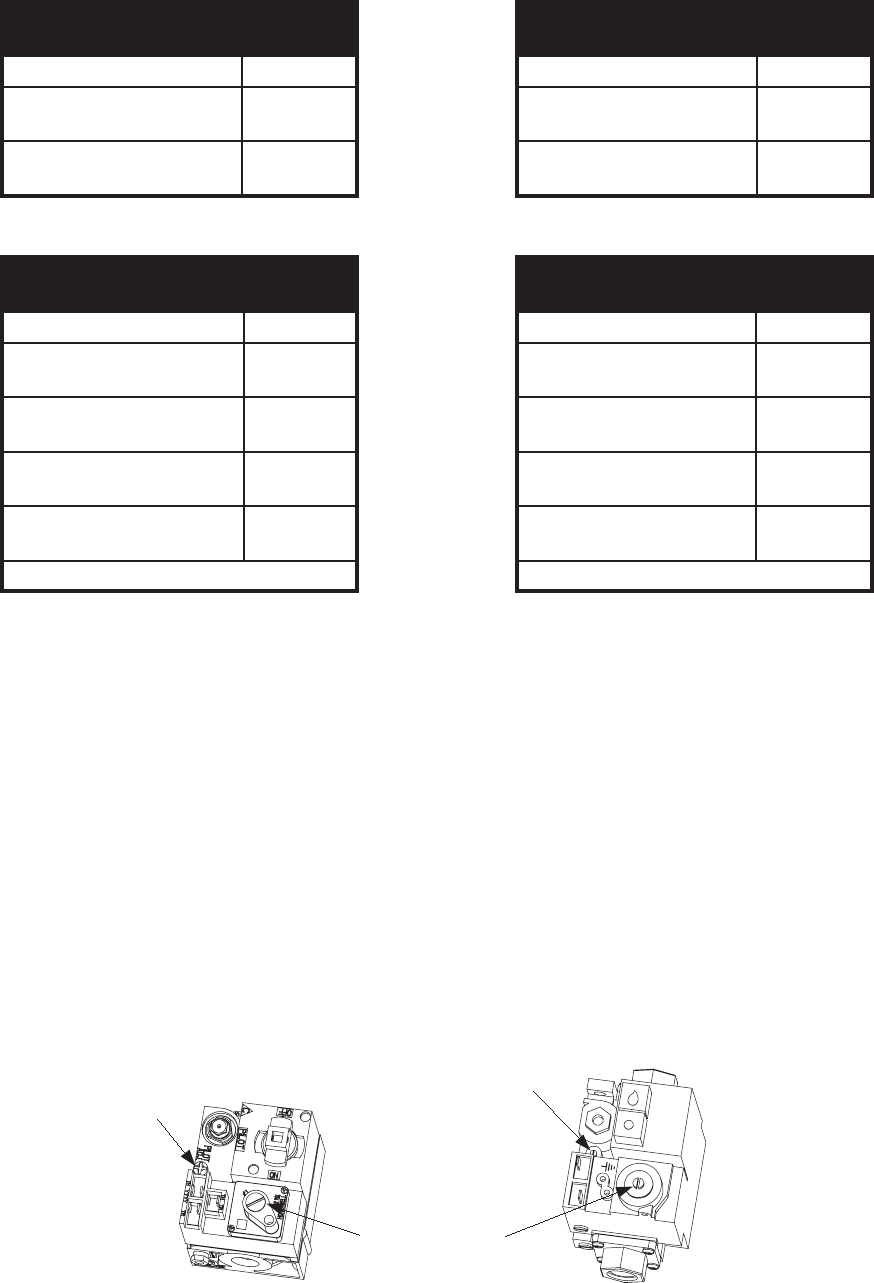

To access the pilot adjustment

screw on non-CE valves, this cap

must be removed.

Pilot Adjustment Screw

Honeywell Valve

(Non-CE Units)

Honeywell Valve

(CE Units)

Gas Valve Regulator

Adjustment Screw

Locating the gas valve regulator adjustment screw and pilot adjustment screw.

35-Series Non-CE Standard

Burner Manifold Gas Pressures

Gas Pressure

Natural

4.0” W.C.

0.87 kPa

Propane

9.0” W.C.

2.24 kPa

35-Series CE Standard

Burner Manifold Gas Pressures

Gas Pressure

Natural Gas Lacq

(G20) under 20 mbar

9 mbar

Natural Gas Gronigue*

(G25) under 25 mbar

11 mbar

Natural Gas Gronigue*

(G20) under 20 mbar

11 mbar

Propane

(G31) under 37 or 50 mbar

22.5 mbar

* Belgian G25 and G20 = 9.0 mbar

45-Series Non-CE Standard

Burner Manifold Gas Pressures

Gas Pressure

Natural

3.5” W.C.

0.73 kPa

Propane

8.25” W.C.

2.05 kPa

45-Series CE Standard

Burner Manifold Gas Pressures

Gas Pressure

Natural Gas Lacq

(G20) under 20 mbar

7.5 mbar

Natural Gas Gronigue*

(G25) under 25 mbar

10 mbar

Natural Gas Gronigue

(G20) under 20 mbar

10 mbar

Propane

(G31) under 37 or 50 mbar

20.6 mbar

* Belgian G25 = 7.0 mbar

8. Use a fl at-head screwdriver to adjust the gas valve regulator adjustment screw to obtain the prescribed

pressure written on the rating plate or one of the charts above. (Use the diagram on below to locate

this screw.) Turn the screw clockwise to increase gas pressure and counterclockwise to decrease gas

pressure.

9. On non-CE units, reinstall the gas valve regulator cap screw when the correct manifold pressure is

obtained.

10. Place the gas valve in the OFF position. Remove the fi tting from the pressure tap hole and reinstall the

pressure tap plug.

11. Place the gas valve in the PILOT position. Re-light and check for any gas leaks.

12. Place the gas valve in the OFF position.