MASTER JET CF SERIES ATMOSPHERIC GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1-29

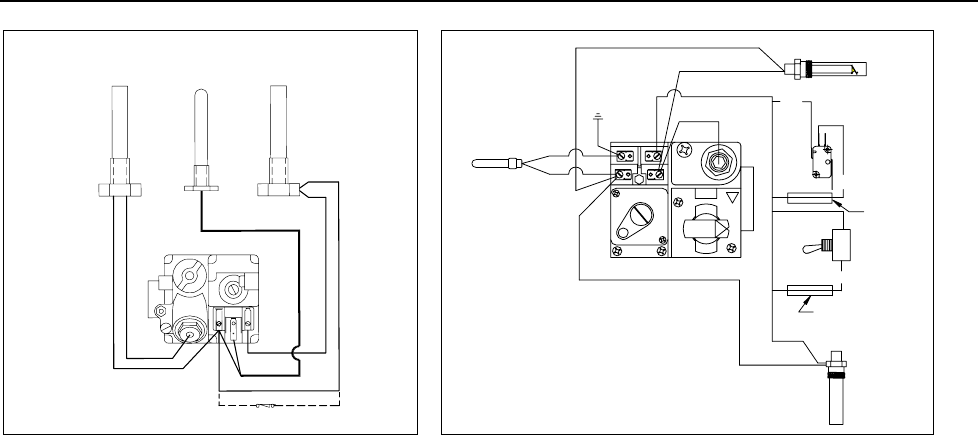

Optional ON-OFF switch

High-Limit

Thermostat

Operating

Thermostat

Pilot

Generator

FENWALL

Operating

Thermostat

HONEYWELL 1/2 P.S.I.

HONEYWELL

1/2 PSI

OFF

ON

PILOT

C

HONEYWELL

1/2 PSI

Pilot

Adj.

High-limit

Thermostat

Pilot

Generator

Safety Drain

Switch

ON/OFF Switch

(Optional)

17C

17C

12C

In Line Splice

In Line Splice

When troubleshooting millivolt systems, always check these areas before performing diagnostic

checks on either the Robertshaw or Honeywell systems:

A. Inspect all wires and component leads for damage (heat, oil, moisture, etc.). On capillary

tube-type thermostats, check for resistance on the thermostat lead wires. Wire nuts and other

connectors cannot be present in a millivolt circuit as they can cause resistance. If resistance

is found, solder the connectors to the wires or replace the wires.

B. Clean and verify that all wire connections and gas valve terminal connections are tight.

C. Check the length of the pilot flame (it should be about 1½-inches (38mm) long) and verify

that it contacts the top one third of the thermopile. Clean the pilot orifice and adjust the pilot

strength if needed.

D. Measure thermopile output with no load (i.e., with the thermopile disconnected from the gas

valve). Measurements must be made with a multimeter having a 0-1000 DC millivolt (MV)

range. Light the pilot and have someone hold the gas cock knob in the depressed position. If

the thermopile is a single lead (coaxial) type, measure from the lead’s end contact to its

screw-in threads. If the thermopile has two leads, measure across the end terminals. The

reading should be within the range of 500-800 millivolts. If not, replace the thermopile.

Performing diagnostic checks on Robertshaw and Honeywell Systems are described on the following

page.