15

Flexible aluminium pipes, corrosion-protected

sheet metal pipes and exhaust air pipes whose

material conforms to fire B1 in accordance with

DIN 4102 can be used. Exhaust air pipes should

have a nominal diameter of 6 ´ ´ / 150 mm.

Pay particular attention to ensuring that

– the exhaust air ducts and pipes are kept as short

as possible

– the pipes are not laid at an acute angle, but as

bends and that they are inserted into the shaft at

an inclined upward angle and

– there are no cross-sectional constrictions in the

upward direction (this reduces the volume flow).

As standard, the blow-out opening of the wall hood

is in the upward direction.

To pass exhaust air through the outer wall, we

recommend the use of our telescopic wall box

TM 150-045 (Ø 6 ´ ´ / 150 mm).

Note:

To prevent the ingress of water, e.g. condensate or

rain water from an uncovered exhaust air shaft, our

condensate separator RV 060-150 must be installed

in the exhaust air line. The condensate separator

must still be acciessible after installation.

The duct units listed below are available

depending on the height of the ceiling:

Stainless steel-design ventilation duct:

LK 530-010 for ceiling heights of

7 ´´ 3 ´ ´ - 8 ´´ 6 ´ ´ / 2.20 - 2.66 m

LK 530-020 for ceiling heights of

8 ´´ 6 ´ ´ - 10 ´´ 1 ´ ´ / 2.66 - 3.15 m

Aluminium-design ventilation duct:

LK 530-011 for ceiling heights of

7 ´´ 3 ´ ´ - 8 ´´ 6 ´ ´ / 2.20 - 2.66 m

LK 530-021 for ceiling heights of

8 ´´ 6 ´ ´ - 10 ´´ 1 ´ ´ / 2.66 - 3.15 m

The dimensions above refer to a distance of 5 ´´ 3 ´ ´ /

1.60 m from the floor to the bottom edge of the

hood.

If required, individually sized ventilation ducts are

available at an extra charge.

The power connection must be placed behind the

duct cover on the wall.

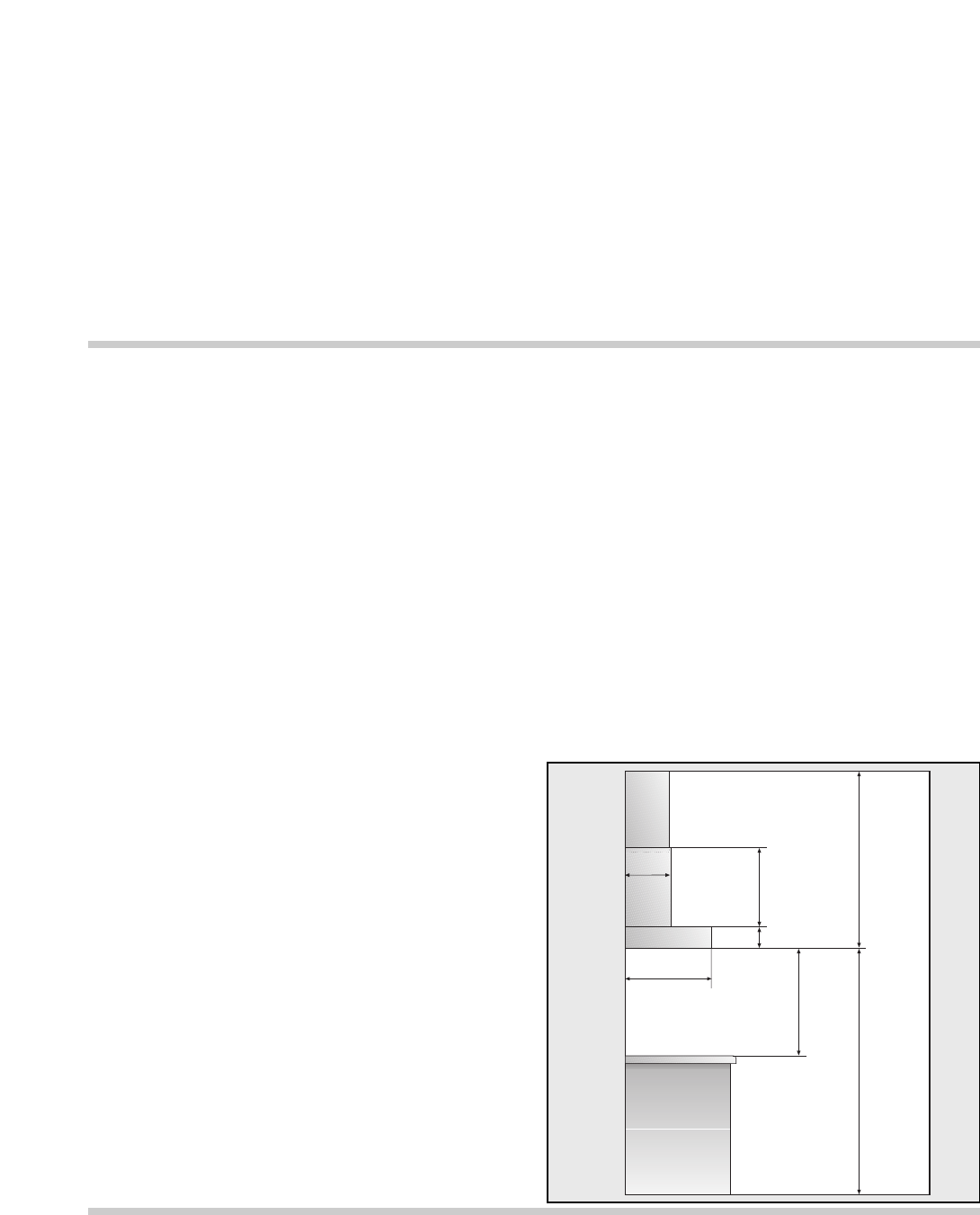

Fig. 18

550

260

100

(3

15

/

16

”)

480

(18

7

/

8

”)

1600

(5’3”)

600-1550 (24”-5’1”) Hood height

min. 600

(24”)

over electric cooker

min. 700

(27

1

/

2

”)

over gas cooker

2,20 - 3,15

(7’3” - 10’1”)

Ceiling height

(10

1

/

4

”)

(21

10

/

16

”)