Shuttle Brewers & Airpot/Shuttle Brewers Page 25

Troubleshooting (cont.)

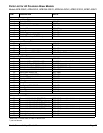

Brewing Problems

Problem Possible Causes Service Check Remedy

Brew volume too

large or too small

• Sprayhead clogged.

• Brew valves clogged

with lime deposits.

• Water supply pressure

or flow rate not

adequate.

• Visually check for

clogging of holes

in brewhead.

• Visually inspect

brew valve at

hose connections.

• Check to see that fill

valve cycles on and

off frequently during

brew cycle when all

brew heads are used

simultaneously. Check

to ensure that water

supply line is 3/8” and

pressure is between

30 and 80 psi (207 and

552 KPA).

• Clean all holes.

• Clean lime from valve. Seat,

cup or entire valve may need

replacement.

• Supply water at adequate

pressure and flow rate.

Brew volume

erratic

• Water supply pressure

fluctuates.

• Check water pressure

with and without other

appliances operating.

• Plumb water supply so that

water pressure is not

significantly affected by

other appliances.

Brew cycle will

not start

• Optional momentary

switch to indicate

container in place not

engaged or faulty.

• Brew circuit connections

not secure.

• Brew valve faulty.

• Touchpad faulty.

• Check to see that

container fully engages

switch. Check for

continuity across switch

when switch is engaged.

• Check to see that

connector (6-pin)

is securely connected to

control board. Check to

see that all connections

from controller through

brew valve are secure.

• Check to see if there is

24 Vac across brew valve

terminals.

• Check to see that

touchpad connections

to control board are

secure.

• If fully engaged switch does

not complete circuit across

terminals of switch, replace

switch.

• Secure connections.

• If there is 24 Vac across

terminals and brew valve is

not open, replace valve.

• If connections are secure,

other functions appear normal

and touchpad will not initiate a

brew cycle, replace touchpad.

Note: Small variations from batch to batch are normal.