9

Venting Safety Guidelines

Installation must be done in accordance with all local and national codes. Use only materials which conform to local codes

in effect. Be sure power is disconnected before doing any electrical work. All duct work must be metal. Do not use plastic

duct. The range hood should never be exhausted into a wall cavity or an attic where an accumulation of grease

could become a fire hazard.

When the installation is completed, turn on the fan and make sure that there are no obstructions in the line.

Gas Line Installation

The Model 7100 / 9100 can be operated on either natural gas or liquid propane (LP) and are set for natural gas OR

propane (LP) gas at the factory. Be sure your range is correctly installed by a qualified serviceman or installer for the

type of gas on which it is to be used.

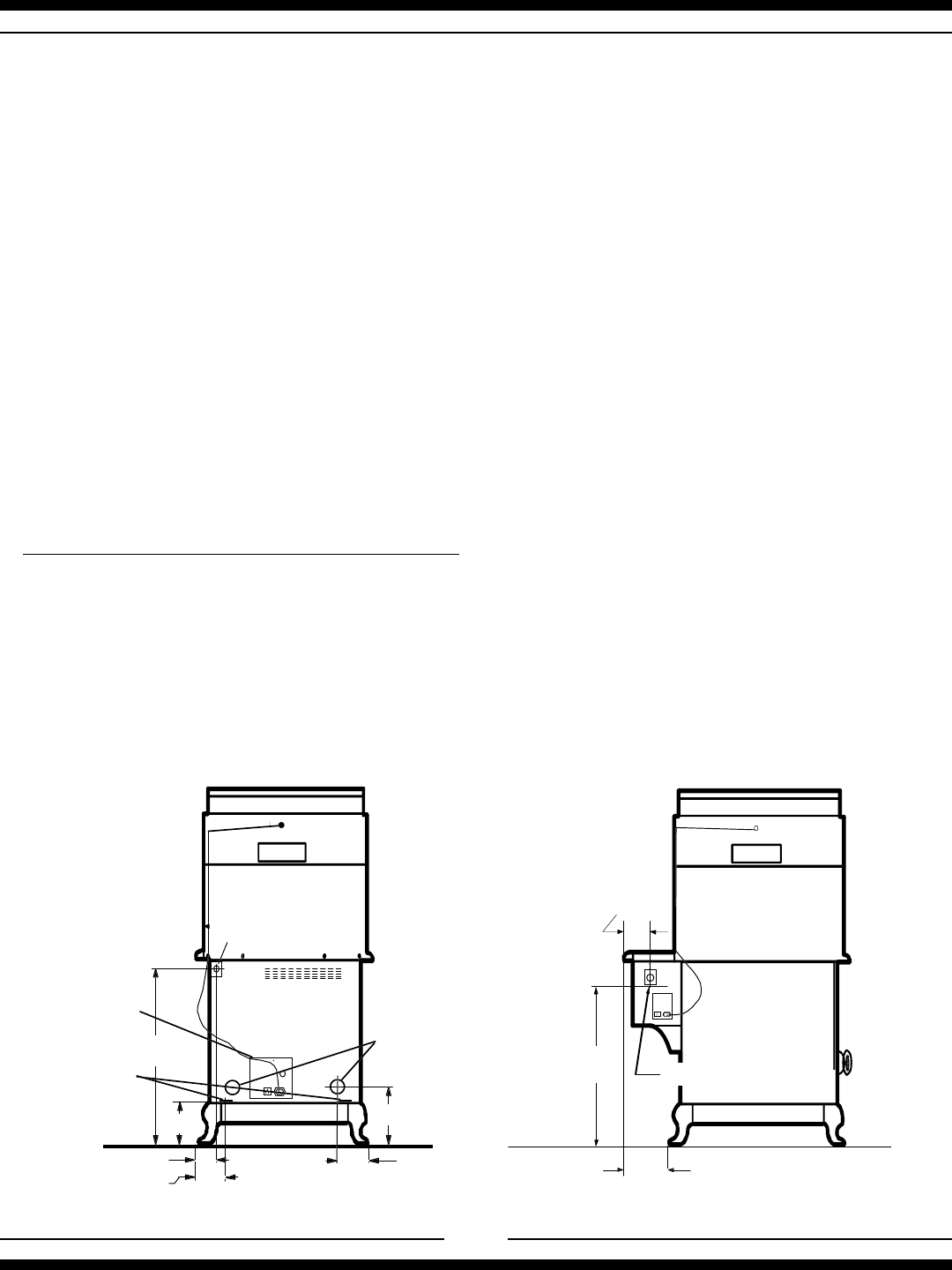

When preparing to install the 9100, be aware that there are several alternative locations for the gas supply pipe to enter

into the stove. For reasons of appearance you may want to conceal the gas supply pipe, and this can be achieved by

routing the supply pipe through knockouts located on the rear or at the bottom of the stove (see illustration below). To

use the alternative locations, the back panel must be disassembled and the selected knockout removed. Route the pipe

through the knockout and up to the manifold. Reassemble the back panel to the stove. Model 7100 has only one supply

pipe installation location. (see illustration below)

THE RANGE MUST BE INSTALLED IN COMPLIANCE WITH LOCAL CODES, AND IN THE ABSENCE OF LOCAL

REQUIREMENTS, THE INSTALLATION MUST CONFORM WITH THE NATIONAL GAS CODE.

Note

: Appliances installed in the state of Massachusetts:

- This appliance can only be installed in the state of Massachusetts by a Massachusetts licensed plumber or

gasfitter

- This appliance must be installed with a three (3) foot / 36 inch long flexible gas connector

- A “T” handle type manual gas valve must be installed in the gas supply line to this appliance

THE APPLIANCE MUST BE ISOLATED FROM THE GAS SUPPLY PIPING SYSTEM BY CLOSING ITS INDIVIDUAL

MANUAL SHUTOFF VALVE DURING ANY PRESSURE TESTING OF THE GAS SUPPLY PIPING SYSTEM AT TEST

PRESSURES EQUAL TO OR LESS THAN 3.5 KPS (1/2 PSIG).

The maximum propane/natural gas supply inlet must not exceed 14 inches of water column. The minimum gas supply

inlet should be at least 5 inches of water column for natural gas or at least 11 inches of water column for LP gas.

Gas Inlet on manifold

All electrical

components

behind panel.

Knock-outs for gas

piping behind back

panel.

Knock-outs for

gas piping in

bottom panel.

5 7/8

149 mm

4 1/2

115mm

3 3/4

95 mm

9 1/2

240 mm

13 3/4

350mm

34

864 mm

5 1/4"

133 mm

30"

762 mm

10"

254 mm

Gas Inlet to manifold

9100 optional gas inlet locations

7100 optional gas inlet location