7

2. Freezers

Service Information

All units are designed for maximum durability, reliability

and simplicity. comes to you ready for operation, fully

charged and with all controls preset at the factory. Instructions

for setting the proper time of day on the freezer defrost/

temperature control are on page 11, steps 1 through 6. The

following information is provided as an aid in the event that

service is required.

Maintenance

The evaporator section of a system should be checked

at least once for proper defrosting because the amount and

pattern of frosting can vary greatly. The frost build-up is

dependent on the temperature of the room, the type of product

being stored, how often new product is brought into the room

and percentage of time the door to the room is open. It may be

necessary to periodically change the number of defrost cycles

or adjust the duration of defrost.

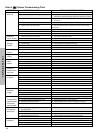

System Standard Maintenance Guidelines

After first year of operation and under normal usage, mainte

-

nance should cover the following items at least once every six

months:

1. Check and tighten

ALL electrical connections.

2. Check all wiring and insulators.

3. Check contactors for proper operation and for worn

contact points.

4. Check all fan motors. Tighten motor mount bolts/ nuts

and tighten fan set screws.

5. Clean the condenser coil surface.

6. Check the operation of the control system. Make certain

all safety controls are operating properly.

7. Check that all defrost controls are functioning properly.

8. Clean the evaporator coil surface.

9. Clean the drain pan and check the drain pan and drain

line for proper drainage.

Sequence of Operation

1. Power is provided to the temperature control,

compressor contactor and cooler evaporator fans.

2. The temperature controller closes and energizes the

compressor contactor, starting the compressor,

evaporator and condenser fan(s).

3. When the system reaches the desired box temperature,

the temperature control will de-energize the compressor

contactor. Evaporator fans will continue to operate at this

point.

4. When the fixture temperature rises above the set point

and minimum off-time has elapsed, the temperature

control will close and re-energize the compressor

contactor.

Freezer Defrost Control -

Med. & Large Cabinet

Freezer units utilize an electronic temperature/defrost control.

This control is fully preprogrammed for temperature and

defrosts. Instructions for any necessary reprogramming are

included in this manual on page 11-13.

Any of the parameters can be modified and the changes will

be stored in the non volitile memory. A capacitor is used to

maintain the time-of-day for up to 100 hours during power

outage.

Electric Defrost Sequence of Operation

for Freezers

1. During normal operation, at the preset times of day, the

temperature/defrost control will de-energize the

compressor contactor and evaporator fans and energize

the defrost heaters. These functions are controlled

through relays on the controller.

2. When the coil has defrosted fully and has reached the

preset coil temperature (as sensed by the coil

temperature sensor) the defrost heater de-energizes

and the fan delay and drip sequences begin.

3. The temperature/defrost control energizes the

compressor contactor, starting the compressor and

condenser fan(s).

4. Freezer evaporator fans will be energized by the

temperature/defrost control when the coil temperature

reaches 35°F or fan delay time has elapsed.

Programming 's Electric Defrost

Controls

's electric defrost control factory settings can be found on

page 4 of this manual.

The control panel initially powers up displaying 12:00 AM

otherwise it will show the last configured selection (time

or temperature). If a power outage occurs during normal

operation, the control will maintain the correct time-of-day up to

100 hours.

To initiate a

Manual Defrost, press and hold the MAN DEF

key for 3 seconds.

There are two levels of programming in the controls. The first

level of security will enable the user to set two parameters:

- Time-of-day (CLoC)

- Setpoint temperature (SEt)

The other level allows access to the other parameters.

Three buttons are used for the programming:

SET, UP and DOWN.

Medium and Large Cabinet Freezers