– 6 –

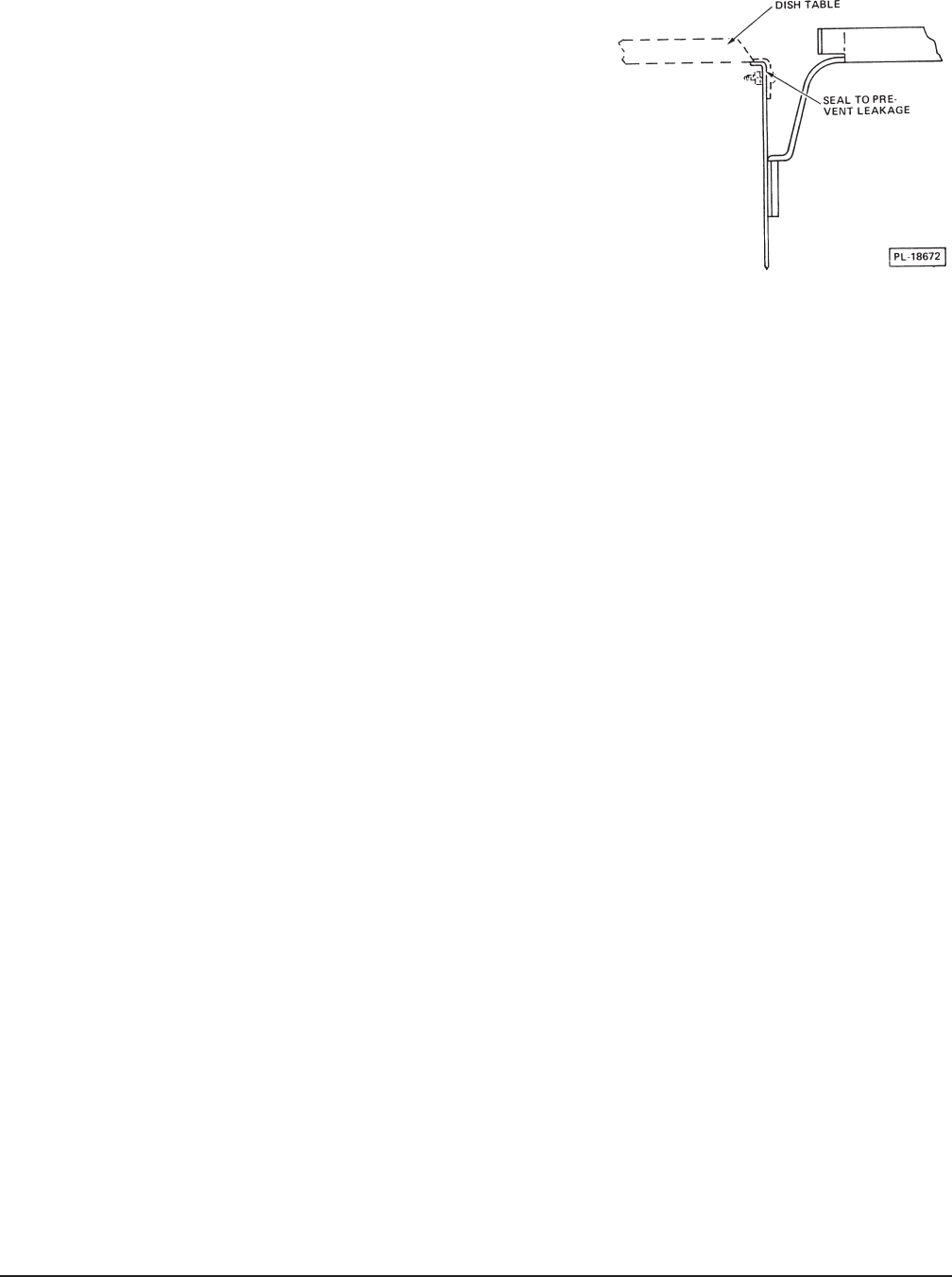

On models AM14T and AM14TC, dish tables should be turned

down and fitted into the dishwasher (Fig. 2). Use an NSF

approved sealer between table and tank lip to prevent leakage.

Fasten the tables to the tank lip with truss head screws. Dish

tables are not required with model AM14F.

High-temperature or gas heat dishwashers will probably require

a hood or vent over the dishwasher in order to meet local codes.

Low-temperature chemical sanitizing machines or low usage

electric heat dishwashers may not require individual venting of

the machine if the room is amply exhausted. Refer to pages 9

and 10 for venting and hood requirements.

WATER REQUIREMENTS

Proper water quality can improve ware washing performance by reducing spotting, lowering chemical

supply costs, enhancing effectiveness of labor, and extending equipment life. Local water conditions

vary from one location to another. The recommended proper water treatment for effective and efficient

use of this equipment will also vary depending on the local water conditions. Ask your municipal water

supplier for details about local water specifics prior to installation.

Recommended water hardness is 4 – 6 grains of hardness per gallon. Chlorides must not exceed 50

parts per million. Water hardness above 6 grains per gallon should be treated by a water conditioner

(water softener or in-line treatment). Water hardness below 4 grains per gallon also requires water

treatment to reduce potential corrosion. Water treatment has been shown to reduce costs associated

with machine cleaning, reduce deliming of the dishwasher, reduce detergent usage, and reduce

corrosion of metallic surfaces in the booster water heater and dishwasher.

Sediment, silica, chlorides, or other dissolved solids may lead to a recommendation for particulate

filtration or reverse osmosis treatment.

If an inspection of the dishwasher or booster heater reveals lime build-up after the equipment has been

in service, in-line water treatment should be considered, and, if recommended, should be installed and

used as directed. Contact your Hobart Service office for specific recommendations.

PLUMBING CONNECTIONS

WARNING:

PLUMBING CONNECTIONS MUST COMPLY WITH APPLICABLE SANITARY, SAFETY,

AND PLUMBING CODES.

DRAIN CONNECTION

The drain connection is made using 2" pipe.

If a right hand drain is desired on a machine with electric heat, it can be changed from the standard

left-hand by removing the pipe plug from the drain valve and reinstalling it in the opposite end of the

drain valve. Machines with gas heat must have the drain connected on the right side.

If a grease trap is required by code, it should have a minimum flow capacity of 42 gallons per minute.

Fig. 2