– 12 –

PL-41059-1

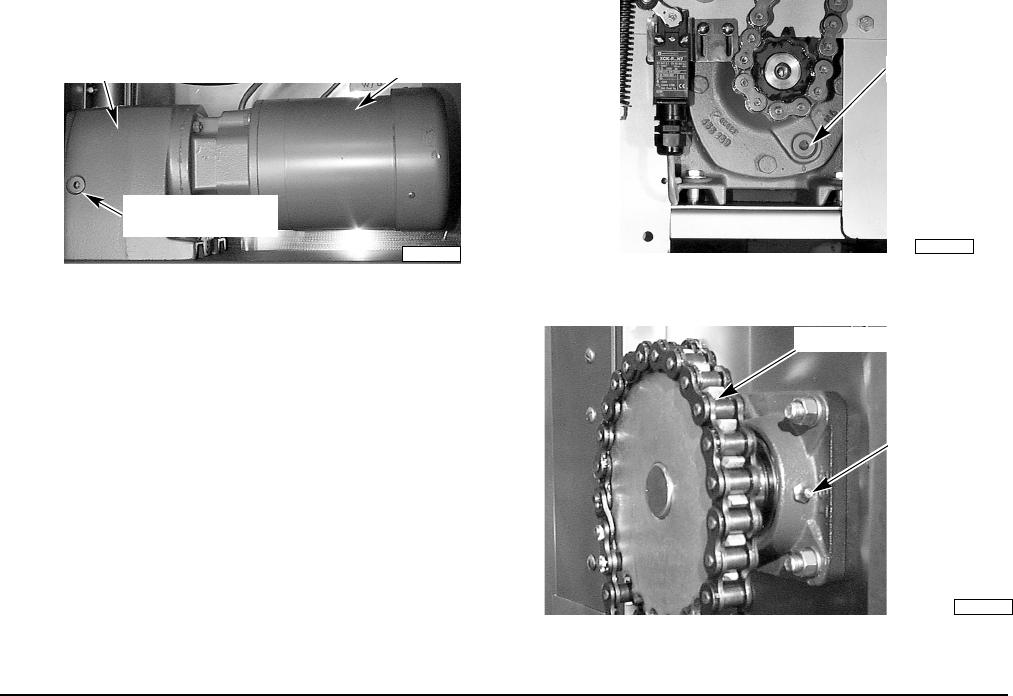

REMOVE PLUG

TO CHECK OIL LEVEL

CONVEYOR MOTOR

GEAR CASE

PL-41060-1

DRAIN PLUG

MAINTENANCE

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY AND PLACE A TAG AT THE

DISCONNECT SWITCH INDICATING THAT YOU ARE WORKING ON THE CIRCUIT BEFORE

PERFORMING ANY MAINTENANCE PROCEDURE.

LUBRICATION

A list of acceptable lubricants, as well as the lubricants themselves, are available from your local Hobart

Service Office.

Line Strainers

Line strainers used in water or steam lines should be cleaned one week after machine installation and

periodically thereafter.

Motors

All motors have sealed bearings and require no lubrication maintenance.

Conveyor Gearmotor

Check the oil level in the conveyor gearmotor at the unload end of the machine every six months by

removing the gear case plug (Fig. 31). The oil level should be at the bottom of the plug hole. The gear

case can be drained from the Drain Plug on the front side (Fig. 32). Use only Mobilgear # 630 to

replenish or replace.

Fig. 31 Fig. 32

Conveyor Drive Chain

Inspect the drive chain (Fig. 33) regularly and

lubricate as required with Grafo Concentrate A

(supplied).

Conveyor Sprocket Bearings

Located at the loading and unloading ends, these

bearings should be lubricated every four months.

Grease fittings (Fig. 33), one at each of the four

bearings, a grease gun, and 4 ounces of Alvania #2

grease are provided for this purpose.

Fig. 33

PL-41058-1

DRIVE CHAIN

GREASE FITTING