– 14 –

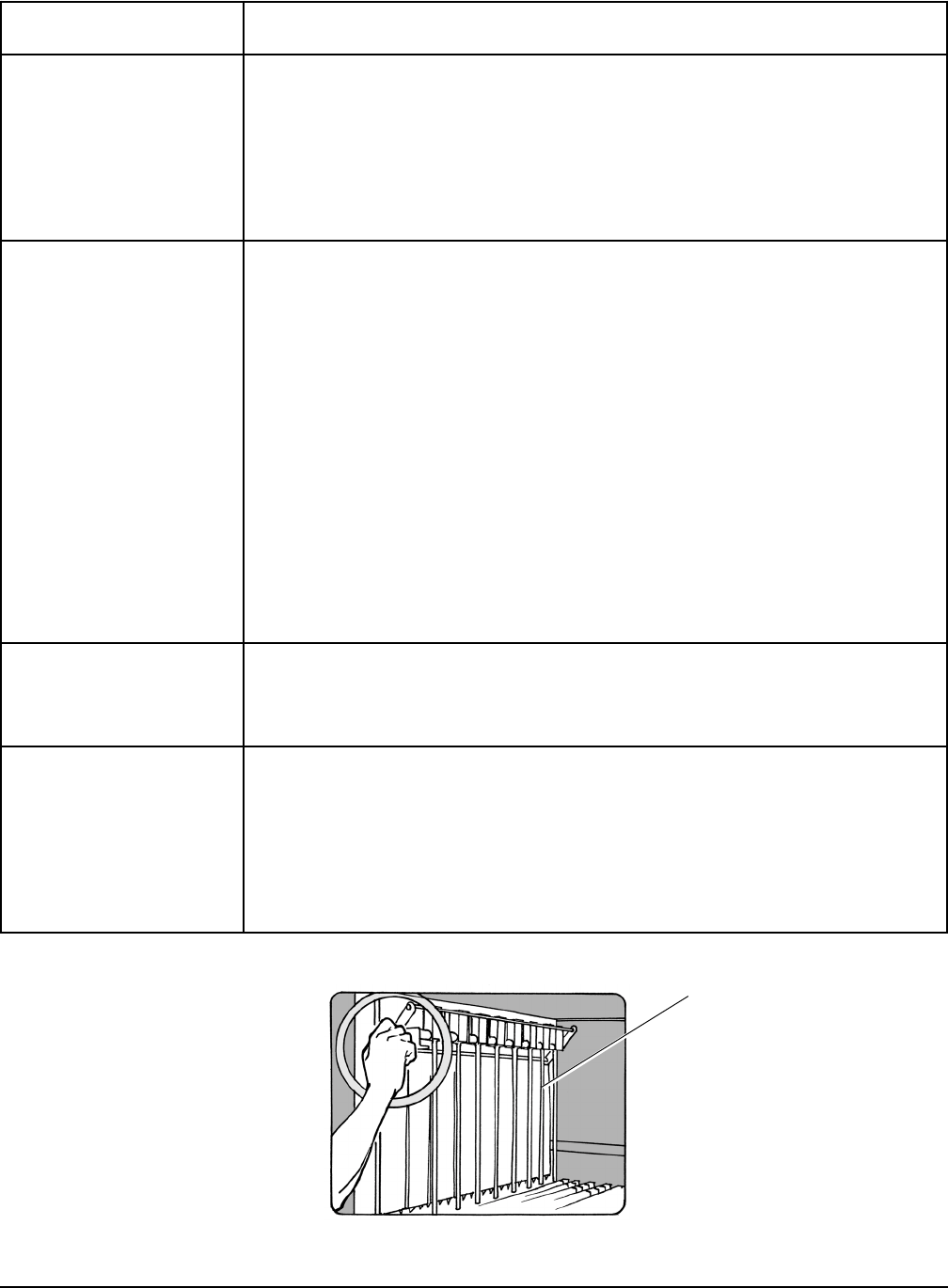

Fig. 35

Rinse Actuator

SYMPTOM POSSIBLE CAUSE

Leaking Valve (Except

Solenoid Type) Supplied

by Others

1.

2.

Foreign material preventing proper valve operation. A critical period is

soon after installation when pipe compound or metal shavings may

lodge at the valve seat. Shut off supply line. Unscrew and lift bonnet

from valve body. Clean valve and reassemble.

If problem is with a solenoid valve, it is recommended that you contact

your local Hobart service office.

Spotting of Silverware,

Glasses, and Dishes.

1.

2.

3.

4.

5.

6.

7.

8.

Improperly loaded dishes.

Incorrect final rinse water temperature (minimum 180°F).

Loss of water pressure due to pump obstruction.

DISCONNECT ELECTRICAL POWER SUPPLY(IES) AND PLACE A

TAG AT THE DISCONNECT SWITCH TO INDICATE YOU ARE

WORKING ON THE CIRCUIT. Drain tank(s) and check for any

obstructions at the pump intake.

Clogged wash arm nozzles.

Improper water hardness (4 – 6 grains / gallon is the recommended

range).

Incorrect detergent for water type.

Clogged rinse nozzle(s).

Misaligned rinse arms. Rinse arms should be positioned so that they

align in hub on chamber wall.

Inadequate Rinse. 1.

2.

3.

Dirty line strainer causing reduced water flow. Turn off water supply.

Low supply line pressure.

Clogged rinse nozzle(s).

Continuous Rinse

Operation (on machines

equipped with Rinse

Actuators, Fig. 35).

1.

2.

3.

Rinse Actuator (Fig. 35) not moving freely.

DISCONNECT ELECTRICAL POWER SUPPLY(IES) AND PLACE A

TAG AT THE DISCONNECT SWITCH TO INDICATE YOU ARE

WORKING ON THE CIRCUIT. Check actuator for movement.

Rinse actuator switch failed. Contact Hobart Service

Rinse valve failed or jammed open. Contact Hobart Service.