52

18) Check for water leaks.

19) Replace the panels in their correct positions.

20) Turn on the power supply.

I. Adjustment of Water Regulating Valve - Water-Cooled Model

The water regulating valve (also called "water regulator") is factory-adjusted. No adjustment

is required under normal use. Adjust the water regulator, if necessary, using the following

procedures.

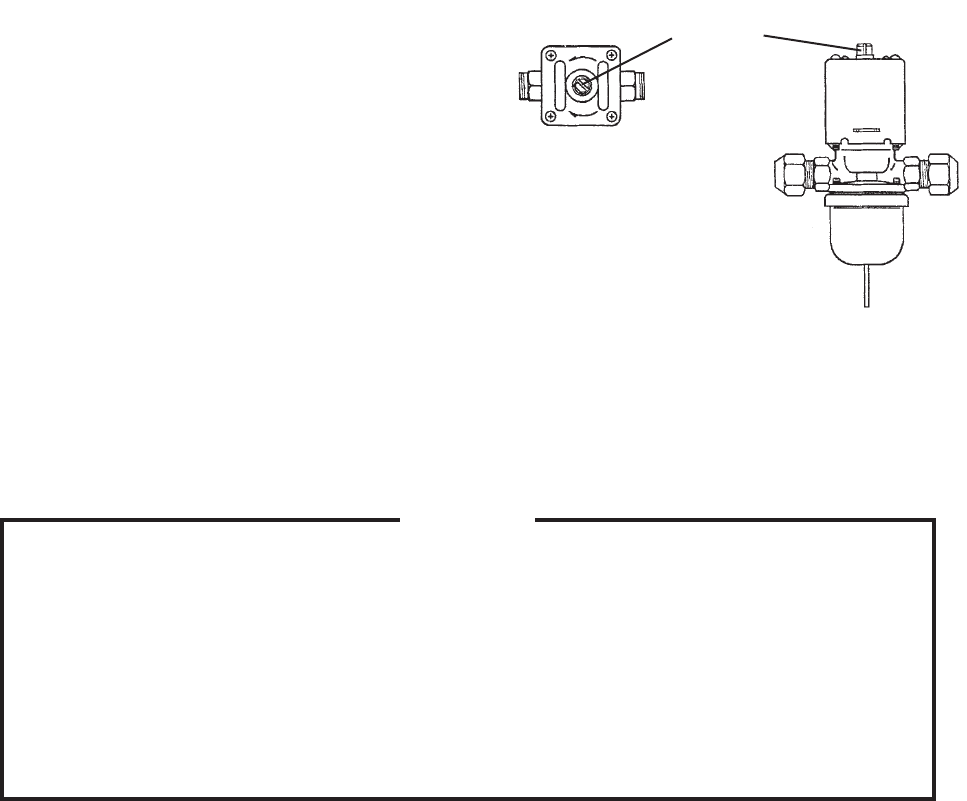

1) Prepare a thermometer to check the condenser drain temperature. Attach a pressure

gauge to the high-side line of the system.

2) Five minutes after a freeze cycle starts,

conrm that the thermometer reads 104°F

to 115°F (40°C to 46°C). If it does not,

rotate the adjustment screw by using a at

blade screwdriver until the temperature is

in the proper range. See Fig. 3. Next, check

that the reference pressure is in the range

indicated in the Head Pressure table in

the Performance Data section. See "III.C.

Performance Data." If it is not in the proper

range, verify the refrigerant charge.

3) Check that the condenser drain temperature is stable.

J. Removal and Replacement of Headmaster (Condensing Pressure

Regulator - C.P.R.) - Remote Air-Cooled Model

CAUTION

1. Always install a new drier every time the sealed refrigeration system is

opened.

2. Do not replace the drier until after all other repair or replacement has been

made. Install the new drier with the arrow on the drier in the direction of the

refrigerant ow.

3. When brazing, protect the headmaster and drier by using wet cloths to

prevent the headmaster and drier from overheating. Do not allow the drier to

exceed 250°F (121°C).

1) Turn off the power supply.

2) Remove the panels from the remote condenser unit.

3) Recover the refrigerant and store it in an approved container.

4) Before heating, break off the stub on the dome to release the dome charge.

5) Disconnect the headmaster.

6) Place the new headmaster in position.

7) Remove the drier, then place the new drier in position.

Fig. 3

Adjustment

Screw

CW – Lower

CCW – Higher

Top View