17

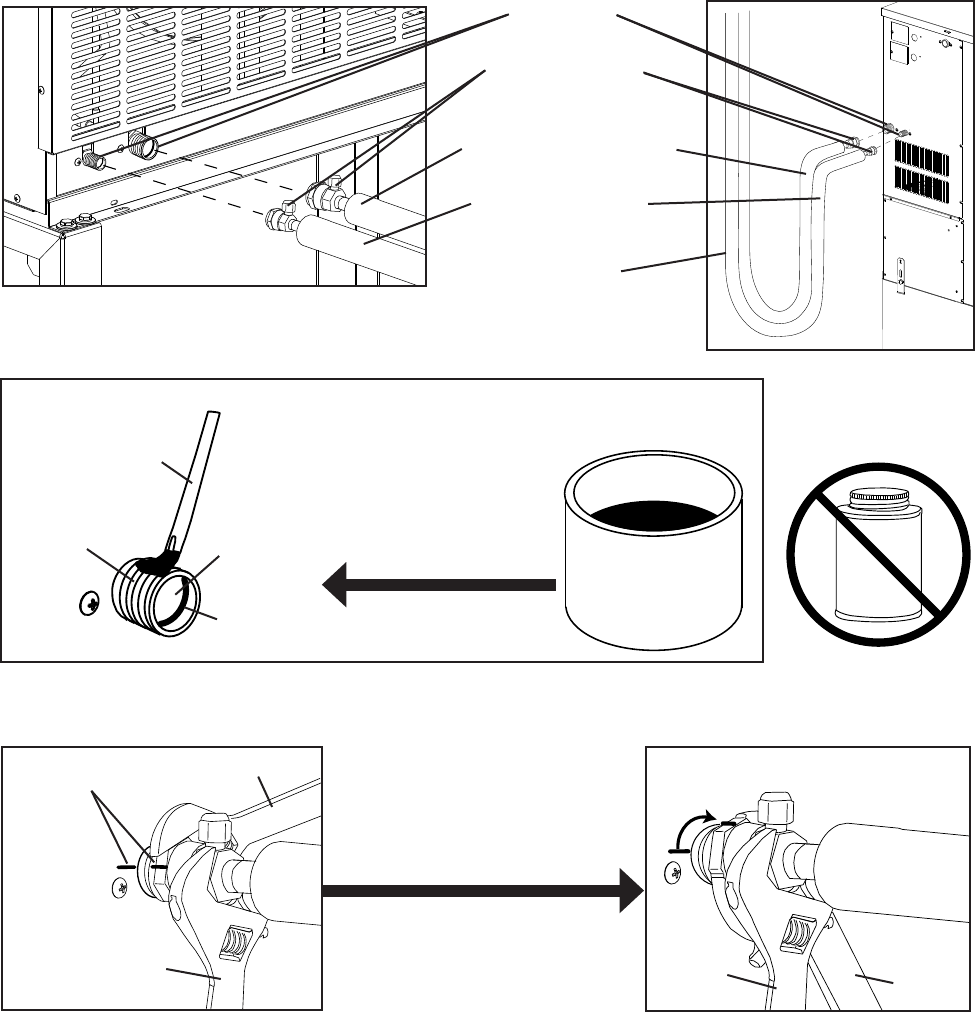

c. Make sure the male tting and female coupling are properly aligned, then start the

connection by hand to ensure that it is not cross threaded.

d. Tighten the connection with a wrench until it is tight. At this point, the nut has

covered most of the threads on the male tting.

e. Mark a reference line on the female coupling and the remote condenser unit or

icemaker panel. Using a backup wrench on the back of the female coupling, tighten

the six-sided nut of the female coupling an additional 1/6 turn. See Fig. 8.

Fig. 6

THREAD

SEALANT

Threads

Diaphragm

O-Ring

Fig. 7

Fig. 8

POLYOL

ESTER

(POE) OIL

Brush

Male Fitting

Apply POE Oil to

Entire Male Fitting

DO NOT USE

THREAD SEALANT

Backup

Wrench

Reference Line

1/6 Turn

Wrench

Wrench

Backup

Wrench

After Tight, Tighten an

Additional 1/6 Turn

Female Coupling

3/8" OD Discharge Line

(Insulated)

Remote Condenser Unit

1/4" OD Liquid Line

(Insulated)

Icemaker

Male Fitting

Service Loop