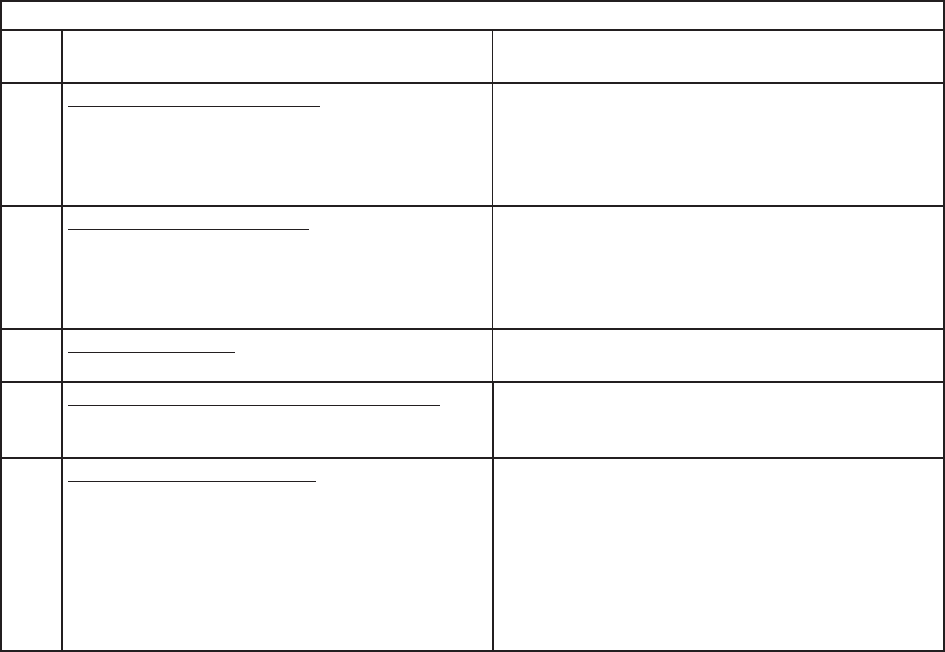

28

Error Codes

Error

Code

Problem Corrective Action/Reset Details

EE

(E5)

High Evaporator Temperature

If evaporator temperature 140°F (60°C) or higher

for 5sec., unit stops.

Check for harvest problem (stuck HGV or control

board relay), hot water entering unit, or shorted

thermistor.

Press the "RESET" button to reset.

EE

(E9)

Condenser Thermistor Error

If condenser thermistor is open or shorted for

2sec., unit stops.

Note: IM-500SAA does not utilize a condenser

thermistor, therefore E9 error will not occur.

Replace condenser thermistor.

EE

(EA)

Control Board Error

If model data IC is defective, unit stops.

Replace control board.

EE

(EC)

Evaporator (Cube Control) Thermistor Error

If evaporator thermistor is open or shorted for

2sec., unit stops.

Replace evaporator thermistor.

EE

(Ed)

Water Regulating Valve Error

If water regulating valve thermistor detects a

temperature below the water regulating valve

error detection temperature (Control Board

Setting 36), error is displayed but unit continues

to operate.

Note: IM-500SAA does not utilize a water

regulating valve, therefore Ed error will not occur.

Check water regulating valve.

Press the "RESET" button to reset.

H. Quick Adjustments

1. Dimple Diameter

The factory set dimple diameter is 3/16" (5 mm). NOTICE! Do not decrease the dimple

diameter below 3/16" (5 mm).

a) To increase dimple diameter:

1) Remove front panel.

2) Press the "SERVICE 1" button to view the current freeze cycle termination temperature

setting.

3) Press the "SERVICE 1" button to raise freeze cycle termination temperature setting

(Control Board Setting 2). Temperature setting rises in .5°C increments. The "." in the

lower, right corner of the display indicates .5°C. Default is -18.5°C. For reference, raising

freeze cycle termination temperature setting to -13°C will result in a dimple diameter of

approximately 3/8" (10mm).

4) Once the display returns to "on" (20 seconds), the new setting is saved.

b) To decrease dimple diameter:

1) Remove front panel.

2) Press the "SERVICE 2" button to view the current freeze cycle termination temperature

setting.