5

GB

PLEASE PHONE US TO REGISTER YOUR APPLIANCE AND ACTIVATE YOUR PARTS GUARANTEE ON 08448 24 24 24

Fig. B Fig. C

Moving the Cooker

Gas connection

The cooker should

be connected to the

gas-supply by a

corgi registered

installer. During

installation of this

product it is

essential to fit an

approved gas tap to

isolate the supply

from the appliance

for the convenience of any subsequent removal or

servicing. Connection of the appliance to the gas

mains or liquid gas must be carried out according to

the prescribed regulation in force, and only after it is

ascertained that it is adaptable to the type of gas to

be used. If not, follow the instructions indicated in

the paragraph headed “Adaptation to different gas

types”. In the case of connection to liquid gas, by

tank, use pressure regulators that conform to the

regulation in force. The gas supply must be

connected to the left of the appliance. Be sure that

the hose does not pass through the rear of the

cooker touching hot parts.

!!

!!

! make sure the supply pressure conforms with the

values shown in the table entitled “Caracteristics of

the burners and nozzles”.

When the cooker is installed betweenWhen the cooker is installed between

When the cooker is installed betweenWhen the cooker is installed between

When the cooker is installed between

cabinets (recessed), the gas connectioncabinets (recessed), the gas connection

cabinets (recessed), the gas connectioncabinets (recessed), the gas connection

cabinets (recessed), the gas connection

must be effected by an approved flexiblemust be effected by an approved flexible

must be effected by an approved flexiblemust be effected by an approved flexible

must be effected by an approved flexible

hose with bayonet fittinghose with bayonet fitting

hose with bayonet fittinghose with bayonet fitting

hose with bayonet fitting

(BS 669 Current Edition). The gas inlet for(BS 669 Current Edition). The gas inlet for

(BS 669 Current Edition). The gas inlet for(BS 669 Current Edition). The gas inlet for

(BS 669 Current Edition). The gas inlet for

the cookers is a threaded G 1/2 gas femalethe cookers is a threaded G 1/2 gas female

the cookers is a threaded G 1/2 gas femalethe cookers is a threaded G 1/2 gas female

the cookers is a threaded G 1/2 gas female

fitting.fitting.

fitting.fitting.

fitting.

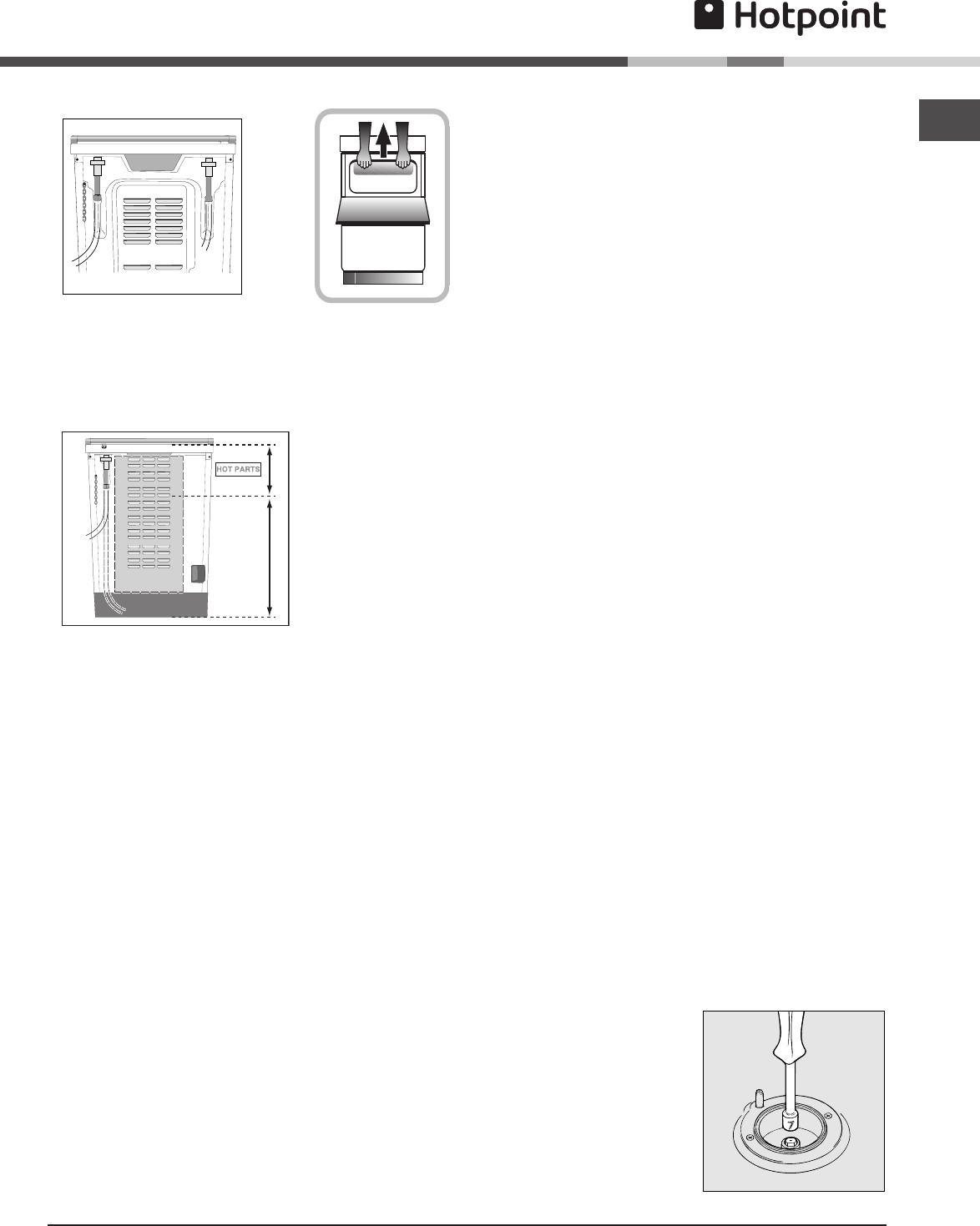

HOT PARTS

600 mm

Connecting the gas supply

To make the connection, a flexible hose should be

used corresponding to the current gas regulations

which are:

• the hose must never be at any point in its

lenght in contact with the “hot” parts

of the cooker;

• the hose must never be longer than 1,5

metre;

• the hose must not be subject to any tension

or torsional stress and it must not

have any excessively narrow

curves or bottlenecks;

• the hose must be easy to inspect along its

entire length to check its condition;

• the hose must always be in good condition,

never attempt to repair.

!!

!!

! the installation must comply with gas safety

(installation and use) regulations 1984. In all cases

for the above, by low, a qualified, corgi approved

engineer must be called for installation.

Disposing of the appliance

When disposing of the appliance please remove the

plug by cutting the mains cable as close as

possible to the plug body and dispose of it as

described above.

Adapting the cooker to different types of gas

In order to adapt the cooker to a different type of

gas with respect to the gas for which it was

produced (indicated on the label attached to the lid),

follow these steps:

a)a)

a)a)

a) replace the hose holder mounted on the

appliance with that supplied in the bag of “cooker

accessories”.

b)b)

b)b)

b) Replacing the burner nozzles on the hob:

•remove the grids and slide the burners from their

housings;

• unscrew the nozzles

using a 7 mm socket

spanner, and replace

them with nozzles for

the new type of gas

(see table 1 “Burner and

nozzle characteristics”).

•replace all the

components by

repeating the steps in

reverse order.

Installation