Flake Ice Machines Refrigeration System

Page F9

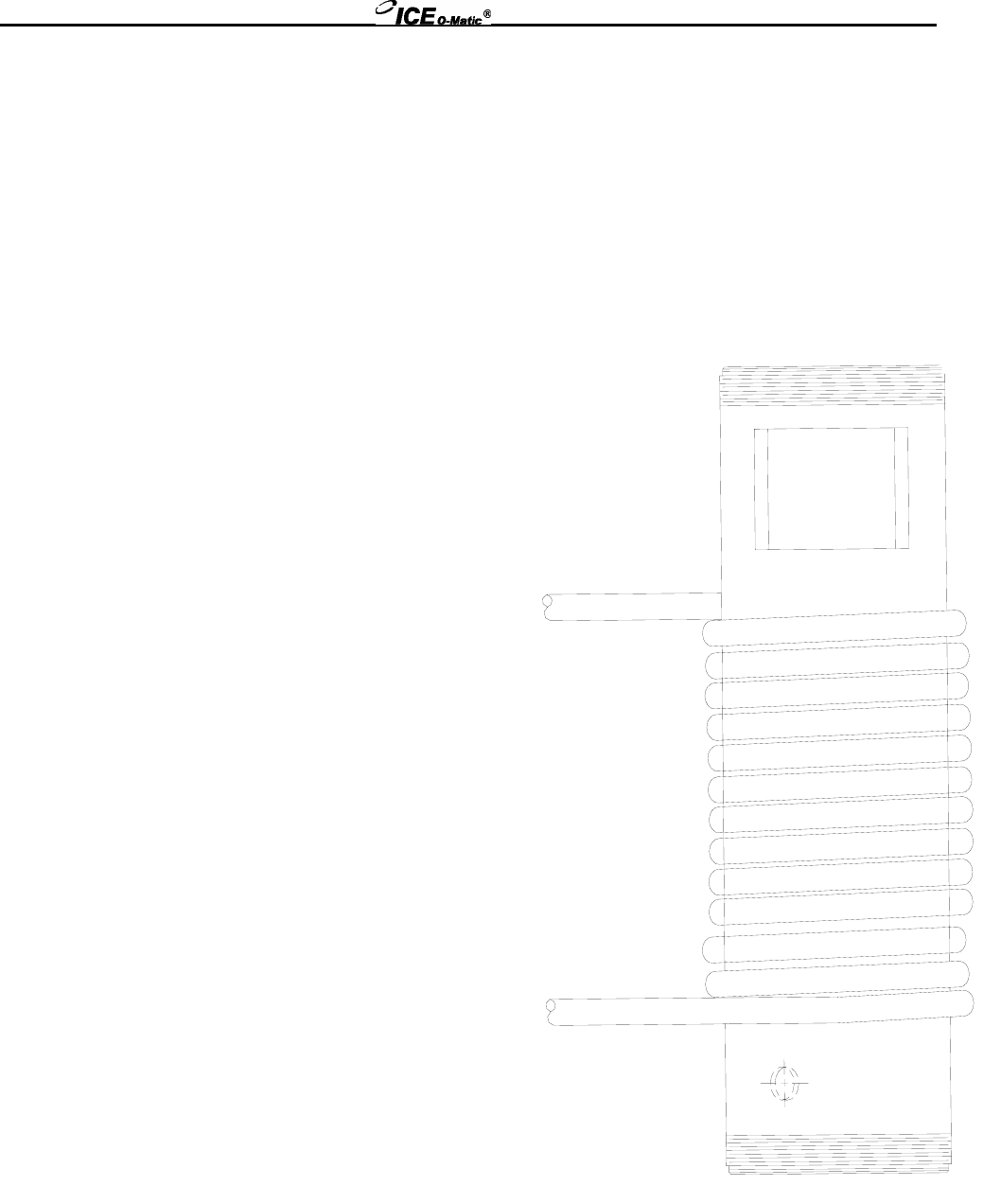

Evaporator

When water fills the evaporator, liquid refrigerant is circulated through the tubing wrapped

around the evaporator. As the liquid refrigerant in the tubing vaporizes, it absorbs heat from

the water, causing it to freeze. The evaporator should be completely flooded with refrigerant

while the machine is making ice.

A flooded evaporator will build ice evenly in the evaporator. A starved evaporator will

produce less ice and the ice will be wetter than normal. Most problems with ice quality or

“freeze ups” are not related to a defective evaporator. Use the Troubleshooting Trees in

Section C for additional help.

If the evaporator is flooded but the suction

pressure is lower than normal and the ice

production is slow, it is possible that the

evaporator has a restriction. If the evaporator is

flooded but the suction pressure is higher than

normal and ice production is slow, it is possible

that the evaporator has coil separation.

Evaporator coil separation is the separation of

the refrigerant tubing from the evaporator barrel.

This is rare but may occur from time to time.

Usually all of the following symptoms will be

present.

• Higher than normal suction pressure.

• Cold or frosted compressor suction line.

• Slow ice production and/or wet ice.

If the coil is separated, the evaporator must be

replaced. If the outlet of the evaporator is not

frosted, the problem is not with coil separation.

(Refer to the Troubleshooting Trees in Section C

As liquid refrigerant leaves the evaporator, it

changes to a low pressure vapor before

returning to the compressor.

Important!

Liquid refrigerant must not return to the

compressor or damage may result. Frost on the

suction line at the inlet of the compressor

indicates liquid may be returning to the

compressor. Check for frost during the freeze

cycle. If liquid refrigerant is returning to the

compressor, the problem must be located and corrected.