Flake Ice Machines Electrical System

Page G4

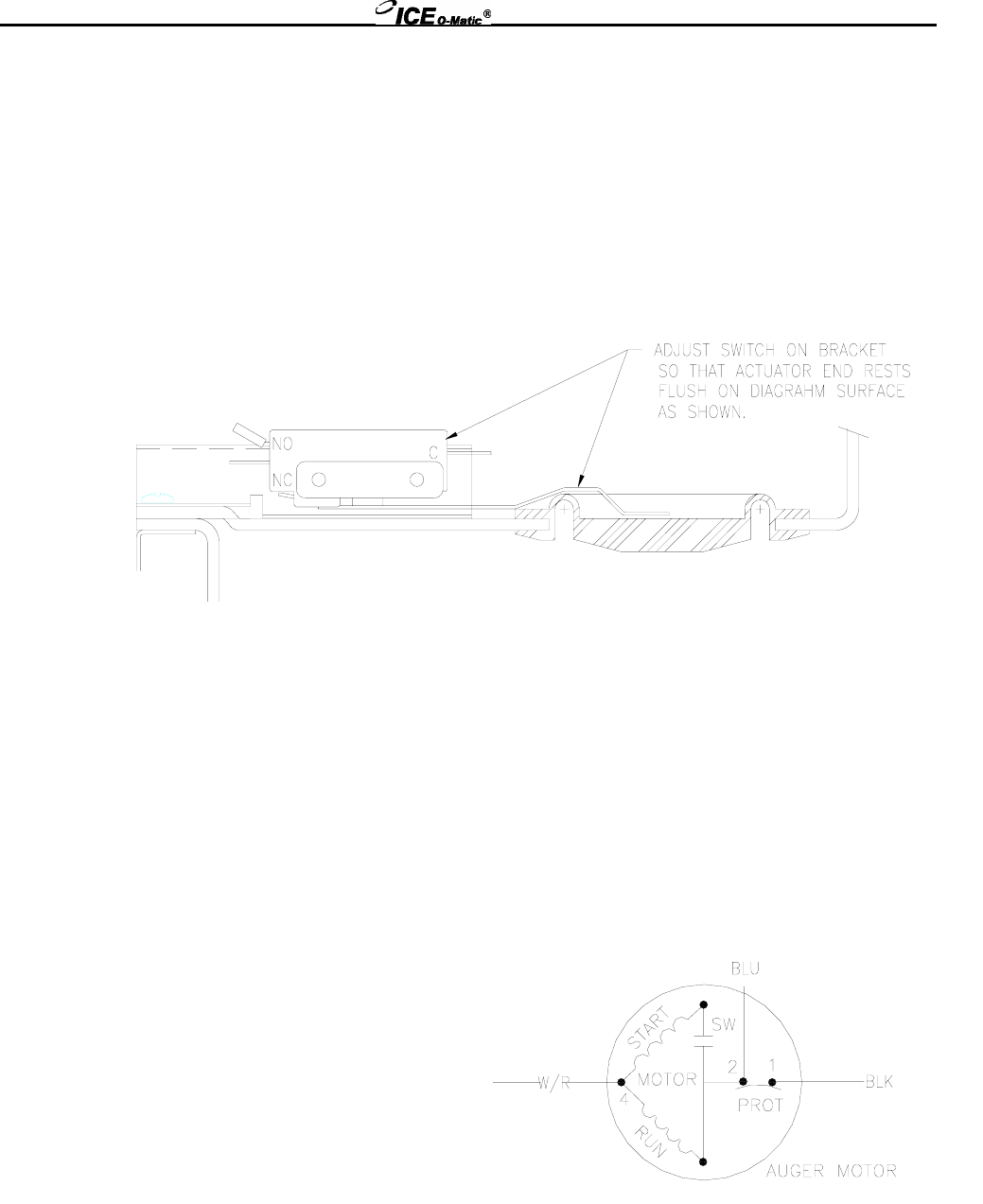

Mechanical Bin Control

The mechanical bin control is located in the top panel of the ice bin on the EF Series and on

the top of the down chute on the EMF Series. When ice fills the down chute on the EMF

Series units, or ice fills the bin on EF Series units a rubber diaphragm pushes up against a

switch.

To check the bin switch, push up on the diaphragm or switch arm raising it approximately 1/8

inch. This movement should actuate (open) the switch. The switch should close when

returned to the normal position. The switch can be adjusted by loosening the adjusting

screws and moving it to the proper position.

Important! The secondary bin switch should only be utilized as a safety. If the machine is

shutting off on the secondary control, the primary control should be adjusted.

Auger Motor Relay

The auger motor relay is used on modular models to energize the auger motor, preventing

excessive current through the bin control. When power is supplied to the coil of the relay, the

normally open contacts close, energizing the auger motor.

Auger Motor

The auger drive motor is used to turn the gear reducer via a V-Belt. The auger motor should

turn counter clockwise when facing the pulley end of the motor.

The auger motor uses an internal overload

protector, which opens if the motor is under

excessive load. If the overload protector

opens, the entire machine will shut off and

will restart when the overload cools and

resets. Problems with the drive system such

as a dirty evaporator or bad bearings are

usually the cause of the overload protector

tripping. This can be checked by reading the

auger motor amp draw. A fluctuation of more

than 4/10 of an amp indicates there may be a

problem in the drive system. See the Troubleshooting Trees on Page C9. Note: When

replacing an auger motor, make sure the new motor is wired properly.