Continuous Flow Icemaker Service Manual

© 2004-2005, IMI Cornelius Inc. - 21 - Publication Number: 630460174SER

TROUBLESHOOTING

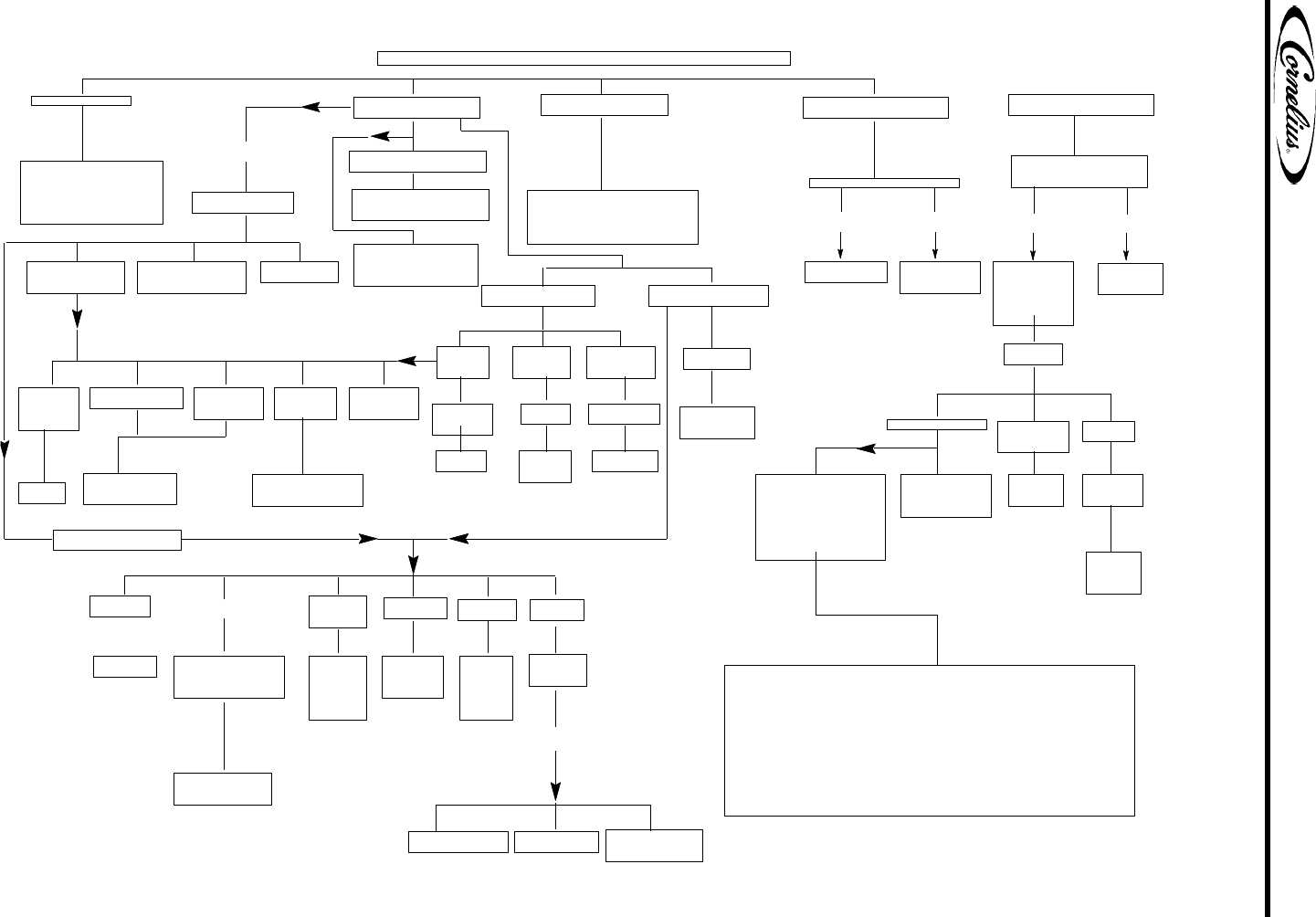

TROUBLESHOOTING CHART - ICEMAKER NOT OPERATING

NO POWER

Check electrical wiring in con

trol box for loose connec

tions.

Check for failed service

switch or relay.

Check power to machine.

ICEMAKER RUNS BUT

DOES NOT MAKE ICE

Condenser fan running

but compressor not running

Check line voltage.

Check compressor winding

& components.

LOW WATER SAFETY

SWITCH OPEN

Remote condenser

not running.

Evaporator water tube

may have an air bubble.

Clear air bubble from

tube.

Check power

to condenser.

Check electrical

wiring in control box

for loose connections.

High pressure

switch open or

cycling on and off.

Check that water is turned on.

Check for restriction in water line.

Check incoming water pressure

(minimum 10 lbs.).

Check water safety switch.

ICEMAKER OPERATING BUT

SOFT ICE

Check bin switch

Clean all related

drain lines.

Refer to guide

to Good Ice in

service manual.

GEARMOTOR OVERLOAD

TRIPPED

Check water level control

and evaporator water tube

for lime build up restriction.

CAUTION

Clear ice from

evaporator and

auger before re

setting over

load.

CLEAN

see

instructions.

Reset

overload.

Icemaker runs

Reset but

motor does

not run.

Will not

reset.

Overload

hot try

again.

Will not

reset

replace

overload

Check

gearmotor

circuit.

Short run trips

again in 2 min

utes. Check gear

motor circuit.

IMPORTANT

Icemaker runs when reset

but problem has not been

found.

Continue checking for

overload as follows to

guard against future

problems

Low suction pressure

(20 lbs. or below).

TXV bulb

lost charge.

Replace valve

evacuate and

recharge.

High suction pressure

(30 lbs. or above).

Suction line

not

insulated.

Bulb

uninsulated.

Clean and

insulate.

TXV not

operating

properly.

Bulb

loose.

Clean

and

tighten.

Head

Pressure

high.

Valve

stuck

open.

Replace

valve.

Condenser

dirty or

restricted.

Condenser

fan not

running.

Too much

refrigerant in

system.

Non-condensible

in system.

Discharge

king valve

partially

closed.

Open

valve

Evacuate and

recharge system.

Clean condenser.

Check electrical circuit

to fan motor.

Check fan motor.

Low pressure switch open

or cycling on and off.

Low on

refrigerant.

Plugged

liquid line

dryer.

Restricted

liquid line.

Plugged or

faulty TXV.

Icemaker

froze up.

Check if

auger is

turning.

Replace

valve.

Evacuate

and

recharge

system.

Check for

kinks or

damage to

liquid line.

Replace

dryer.

Evacuate

and

recharge

system.

LAC not operating

properly (minimum

discharge pressure

180 lbs.).

Check for

leaks.

Replace LAC valve,

evacuate and

recharge system.

Check drive on

gearmotor.

Check gears in

gearbox.

Check if extruding

head is down in

evaporator tube.

OVERLOAD GUIDE

ELECTRICAL

High or low voltage weak power lines can cause overloads on icemaker restarts

High running current. Check motor circuits and start relay - Auger delay failed.

ICEMAKER

Mechanical parts worn. Scored evaporator or auger. Worn thrust bearing.

Ice maker not turning off. Failed ice level control.

Over compression. Low water inlet temperature. Restriction in water line from

reservoir.

REFRIGERANT

Contaminated charge or bad compressor.

Low charge or gas leak.

Low suction pressure. Improper expansion valve sensing bulb. Location or insulation

and/or defective expansion valve

No

Remote condenser

units only

Remote condenser

units only

No

Ye s

Ye s

No