JFT Series Technical Manual 7610-002-77-38

Issued: 03-16-2006 Revised: N/A

16

SECTION 2: INSTALLATION/OPERATION INSTRUCTIONS

INSTALLING THE JFT DISHMACHINE (CONTINUED)

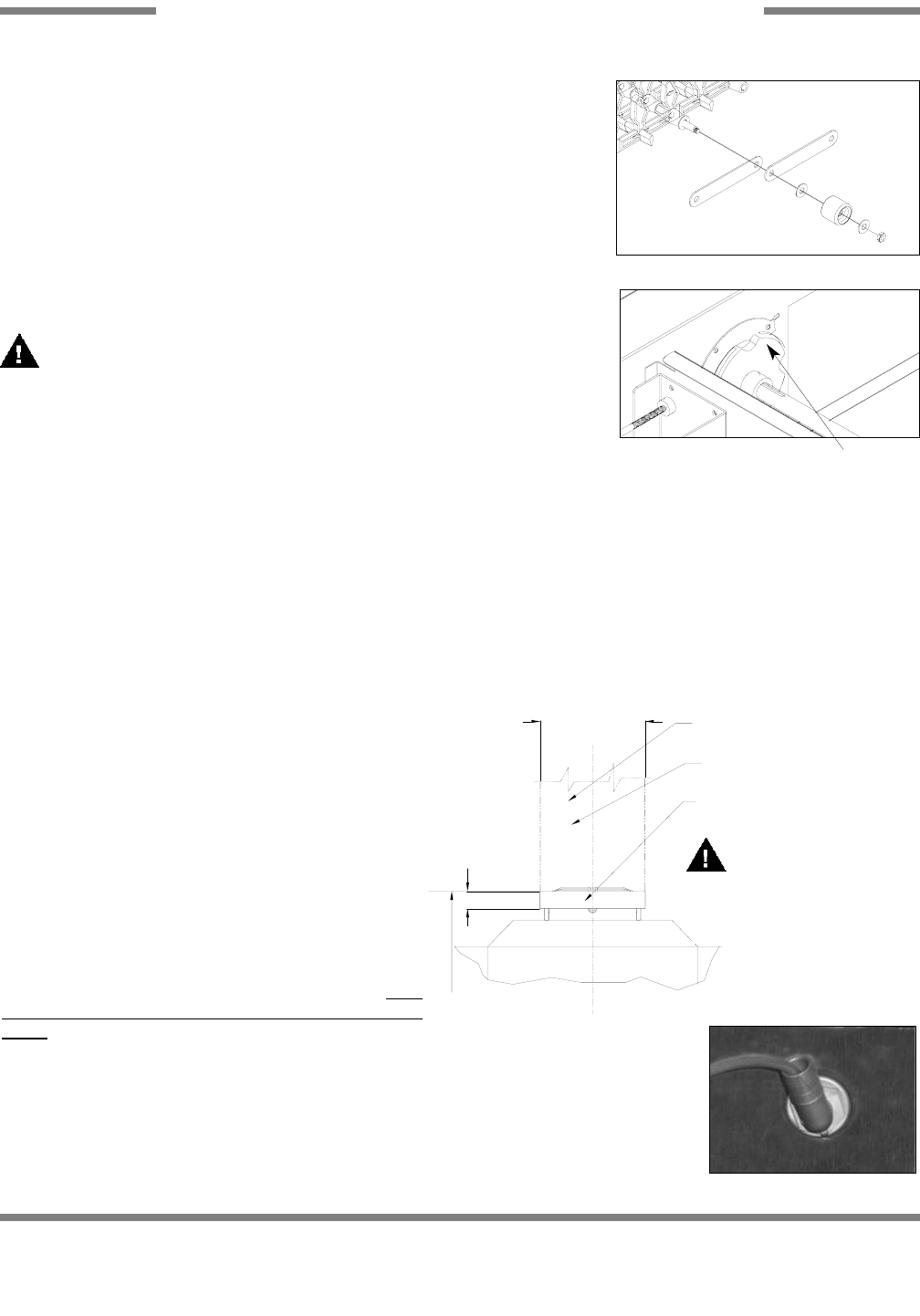

gram to see the order in which the provided washers, wheels, locknuts, and plate

connectors are arranged for proper operation. Continue this process of pulling sec-

tions through and connecting sections until the belt is completely installed. Note:

Take care that the belt wheels are guided correctly at the unload section and fall with-

in the depressions on the drive wheels (Please refer to the page entitled “Unload End

Assembly”). The wheels must be placed on top of the lower belt rails before contin-

uing the process. When the lead end of the transport belt returns back to the load

end of the machine, ensure that it will overlap the last section of the belt added.

Remove as many rod sections of either end as to make the connection between both

ends.

Pay attention to the cross-struts of the machine. Be careful to not place fingers

through the belt! Your hand could be injured.

The dishmachine has two transport speeds. The transport speed can be adjust-

ed during operation from low to high or vice versa by adjusting the conveyor speed

switch located on the electrical cabinet.

BELT TENSION: It must be possible to lift up the belt in the section of the free feed-

ing or discharge zone by approximately 2” to 4”. The tension station can be adjusted

by loosening the three bolts on each of the two slotted adjusting plates. Pull each plate back until all wheels along the plates

perimeter are firmly touching. Tighten the bolts. Visually inspect the belt for parallelism and ensure the plates are evenly tight-

ened by measuring their distance from the runoff sheet or the end plate. Check tension by pulling the belt off of the top rails by

hand. There should be no greater than a 4” separation. If there is, loosen the slotted adjusting plates, remove one rod section

of the belt and repeat the tensioning process.

INSTALLATION OF DRIVE MOTOR CHAIN: Install chain around large gear. Lift gear motor from bottom to apply tension to

drive springs. Install chain over small gear and release gear motor. Drive springs will automatically tighten chain to it’s proper

tension.

VENTILATION OF DISHMACHINE: The dishmachine

should be located with provisions for venting into an ade-

quate exhaust hood or ventilation system. This is essential

to permit efficient removal of the condensation exhaust.

Ensure that the exhaust system is acceptable in accor-

dance with all applicable codes and standards.

This units covered in this manual have the following

exhaust requirements:

FPM (INDIRECT) 1200

The exhaust system must be sized to handle this volume

for the dishmachine to operate as it was designed to.

ELECTRIC HEAT: The thermostats are factory set. They

should not be adjusted except by an authorized service

agent.

CONNECTION FOR THE DETERGENT SUPPLIER: The detergent connection point is at the rear

of the wash section on the machine.

Chemical feeder equipment must not be mounted inside the main control box. Contact your local

chemical distributor for more information regarding chemical feeders.

A.F.F.

6'-10"

3" DEEP

18" I.D. SQUARE

CONDENSATE DUCT PAN MOUNTED ON

TOP OF DISHMACHINE ELECTRICAL

SECTION.

CONDENSATE EXHAUST DUCT.

MINIMUM 18" SQUARE (CROSS SECTION 324

SQ INCHES)

PROVIDED BY HVAC CONTRACTOR

CONDENSATE DUCT TO EXTEND

INTO DUCT PAN

Unload End Assembly - Drive Wheel

Transportation Belt Hardware

NOTE: Damage caused

by steam or moisture

due to improper ventilation

is NOT covered under the

warranty.

Detergent Connection