Tempstar LT/NB/S/SDS Technical Manual 7610-011-86-35

Issued: 12-07-2007 Revised: N/A

SECTION 2: INSTALLATION/OPERATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS

9

VISUAL INSPECTION: Before installing the unit, check the container and machine for damage. A damaged container is an indi-

cator that there may be some damage to the machine. If there is damage to both the container and machine, do not throw away

the container. The dishmachine has been inspected and packed at the factory and is expected to arrive to you in new, undamaged

condition. However, rough handling by carriers or others may result in there being damage to the unit while in transit. If such a sit-

uation occurs, do not return the unit to Jackson; instead, contact the carrier and ask them to send a representative to the site to

inspect the damage to the unit and to complete an inspection report. You must contact the carrier within 48 hours of receiving the

machine. Also, contact the dealer through which you purchased the unit.

UNPACKING THE DISHMACHINE: Once the machine has been removed from the container, ensure that there are no missing

parts from the machine. This may not be obvious at first. If it is discovered that an item is missing, contact Jackson immediately to

have the missing item shipped to you.

LEVEL THE DISHMACHINE: The dishmachine is designed to operate while being level. This is

important to prevent any damage to the machine during operation and to ensure the best results

when washing ware. The unit comes with adjustable bullet feet, which can be turned using a pair of

channel locks or by hand if the unit can be raised safely. Ensure that the unit is level from side to

side and from front to back before making any connections.

PLUMBING THE DISHMACHINE: All plumbing connections must comply with all applicable local, state, and national plumbing

codes. The plumber is responsible for ensuring that the incoming water line is thoroughly flushed prior to connecting it to any com-

ponent of the dishmachine. It is necessary to remove all foreign debris from the water line that may potentially get trapped in the

valves or cause an obstruction. Any valves that are fouled as a result of foreign matter left in the water line, and any expenses

resulting from this fouling, are not the responsibility of the manufacturer.

CONNECTING THE DRAIN LINE: The drain for the Tempstar models covered in this manual are gravity discharge drains. All pip-

ing from the 1 1/2” FNPT connection on the wash tank must be pitched (1/4” per foot) to the floor or sink drain. All piping from the

machine to the drain must be a minimum 1 1/2” I.P.S. and shall not be reduced. There must also be an air gap between the machine

drain line and the floor sink or drain. If a grease trap is required by code, it should have

a flow capacity of 5 gallons per minute.

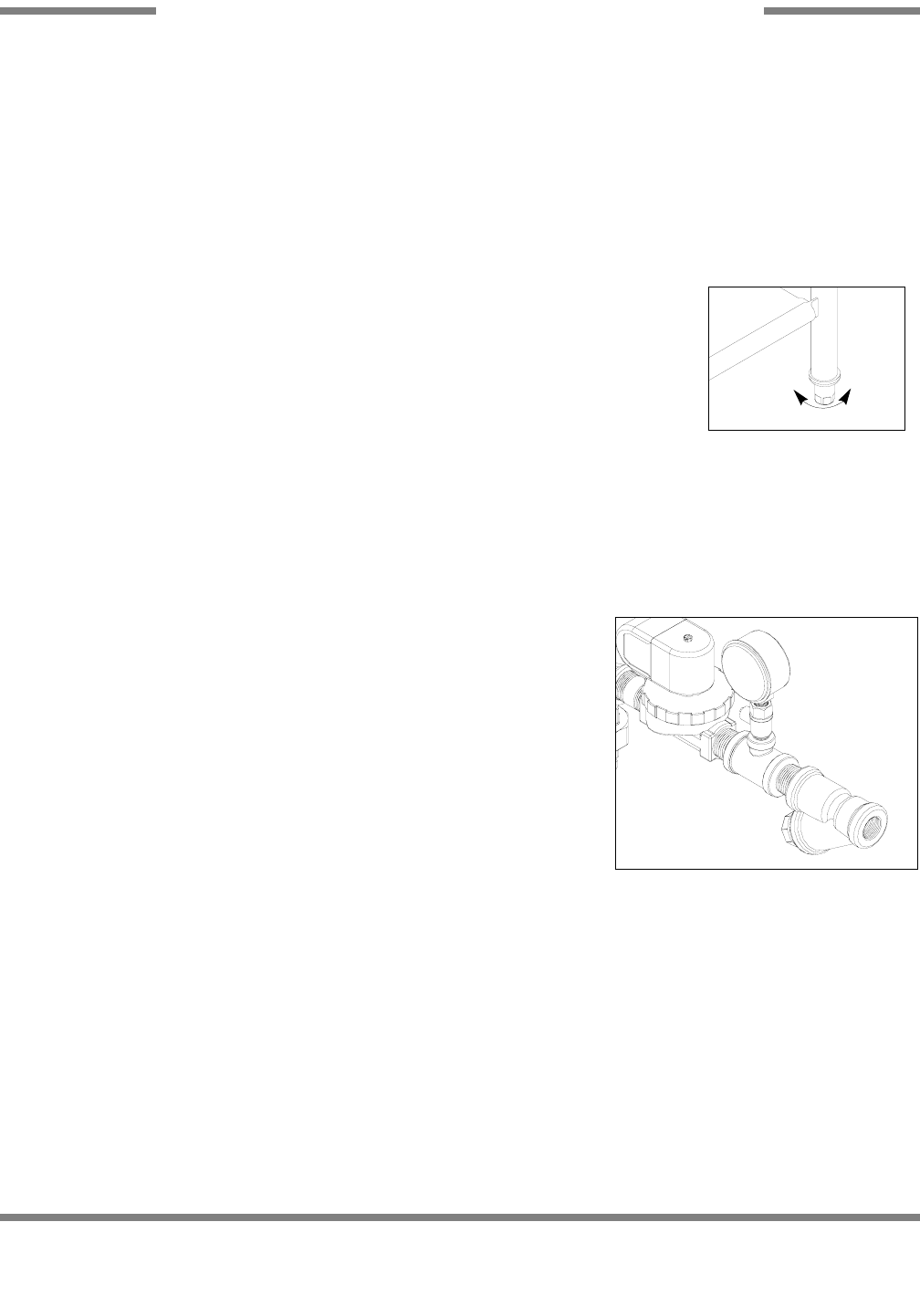

WATER SUPPLY CONNECTION: Ensure that you have read the section entitled

“PLUMBING THE DISHMACHINE” above before proceeding. Install the water supply

line (3/4” pipe size minimum) to the dishmachine line strainer using copper pipe. It is

recommended that a water shut-off valve be installed in the water line between the

main supply and the machine to allow access for service.

The water supply line is to be capable of 20 ±5 PSI “flow” pressure at the recom-

mended temperature indicated on the data plate.

In areas where the water pressure fluctuates or is greater than the recommended pres-

sure, it is suggested that a water pressure regulator be installed. The Tempstar models

covered in this manual come with water pressure regulators as standard equipment.

Please notify Jackson immediately if this component is not present on your machine.

Do not confuse static pressure with flow pressure. Static pressure is the line pressure in a “no flow” condition (all valves and ser-

vices are closed). Flow pressure is the pressure in the fill line when the fill valve is opened during the cycle.

It is also recommended that a shock absorber (not supplied with the Tempstar model) be installed in the incoming water line. This

prevents line hammer (hydraulic shock), induced by the solenoid valve as it operates, from causing damage to the equipment.

STEAM LINE CONNECTION: The steam machines come with lines by which the source steam needs to be connected. Connect

all steam lines to the machine as all applicable codes provide. See machine data plate for information concerning steam flow pres-

sure.

CHEMICAL DISPENSING EQUIPMENT: The Tempstar LT machine requires that a separate chemical feeder be connected to it to

provide the required detergent and sanitizer. This feeder needs to be able to operate against a head of 25 PSI and provide 1.79

ml of a 10% Chlorine sanitizer per minute.

Frame with Adjustable Foot

Raise

Lower

Incoming Plumbing Y-strainer Connection