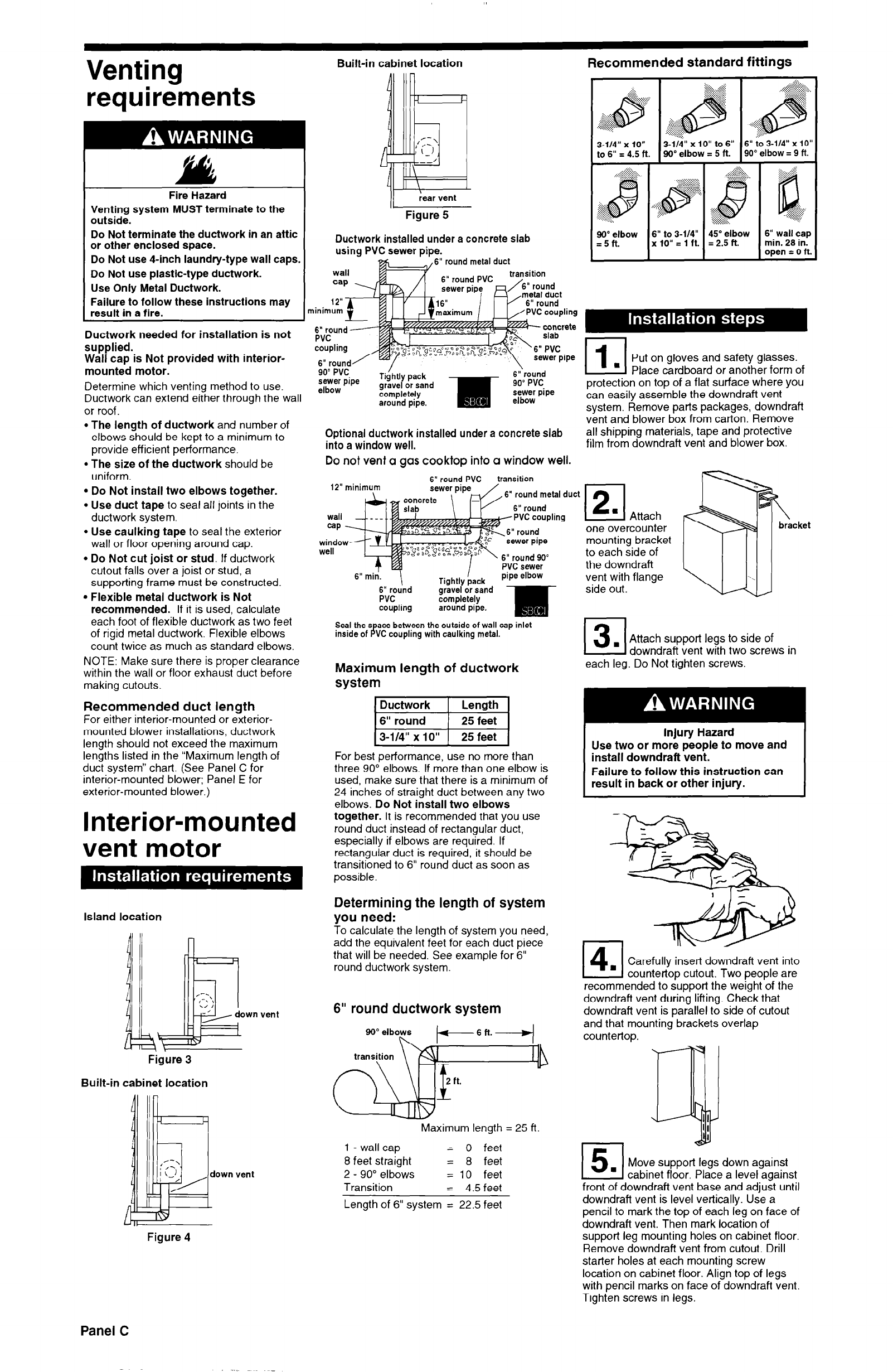

Venting

requirements

Built-in cabinet location

Recommended standard fittings

3-,,4” x ,o” =II

3.114 x 10” to 6” 6” to 3-114” x IO”

to 6” = 4.5 ft.

90” elbow = 5 ft.

90” elbow = 9 ft.

:.-;-.

. . . . . . . . . . . . . -.

..:.:.:.:.:.

-.-

. . . . . . . . . . . . . . . .

90” elbow

6” to 3.114” 45” elbow

6” wall cap

= 5 ft.

x 10” = 1 ft. = 2.5 ft.

min. 28 in.

open = 0 ft.

Fire Hazard

Venting system MUST terminate to the

outside.

Do Not terminate the ductwork in an attic

or other enclosed space.

Do Not use 4-inch laundry-type wall caps.

Do Not use plastic-type ductwork.

Use Only Metal Ductwork.

Failure to follow these instructions may

result in a fire.

I/ iear vent

Figure 5

Ductwork installed under a concrete slab

using PVC sewer pipe.

6” round metal duct

Ductwork needed for installation is not

supplied.

Wall cap is Not provided with interior-

mounted motor.

Determine which venting method to use.

Ductwork can extend either through the wall

or roof.

l

The length of ductwork and number of

elbows should be kept to a minimum to

provide efficient performance.

l

The size of the ductwork should be

uniform.

l

Do Not install two elbows together.

l

Use duct tape to seal all joints in the

ductwork system.

l

Use caulking tape to seal the exterior

wall or floor opening around cap.

l

Do Not cut joist or stud. If ductwork

cutout falls over a joist or stud, a

supporting frame must be constructed.

. Flexible metal ductwork is Not

recommended. If it is used, calculate

each foot of flexible ductwork as two feet

of rigid metal ductwork. Flexible elbows

count twice as much as standard elbows.

NOTE: Make sure there is proper clearance

within the wall or floor exhaust duct before

making cutouts.

Recommended duct length

For either interior-mounted or exterior-

mounted blower installations, ductwork

length should not exceed the maximum

lengths listed in the “Maximum length of

duct system” chart. (See Panel C for

interior-mounted blower; Panel E for

exterior-mounted blower.)

II

.

Put on gloves and safety glasses.

Place cardboard or another form of

protection on top of a flat surface where you

can easily assemble the downdraft vent

system. Remove parts packages, downdraft

vent and blower box from carton. Remove

all shipping materials, tape and protective

film from downdraft vent and blower box.

90” PVC

sewer pipe

elbow

Tig/htly pack

gravel or sand

completely

around pipe.

6”round

90” PVC

sewer pipe

elbow

Optional ductwork installed under a concrete slab

into a window well.

Do not vent a gas cooktop into a window well.

6” round PVC

transition

6” round metal duct

(2

. Attach

one overcounter

mounting bracket

to each side of

the downdraft

vent with flange

side out.

6” mii.

6” round

PVC

coupling

Tightly back

pipe elbow

gravel or sand

completely

around pipe.

Attach support legs to side of

downdraft vent with two screws in

Seal the s ace between the outside of wall cap inlet

inside of B VC coupling with caulking metal.

each leg. Do Not tighten screws.

Maximum length of ductwork

system

For best performance, use no more than

three 90” elbows. If more than one elbow is

used, make sure that there is a minimum of

24 inches of straight duct between any two

elbows. Do Not install two elbows

together. It is recommended that you use

round duct instead of rectangular duct,

especially if elbows are required. If

rectangular duct is required, it should be

transitioned to 6” round duct as soon as

possible.

Injury Hazard

Use two or more people to move and

install downdraft vent.

Failure to follow this instruction can

result in back or other injury.

Interior-mounted

vent motor

Determining the length of system

you need:

To calculate the length of system you need,

add the equivalent feet for each duct piece

that will be needed. See example for 6”

round ductwork system.

Island location

I - I

14

. Carefully insert downdraft vent into

countertop cutout. Two people are

recommended to support the weight of the

downdraft vent during lifting. Check that

downdraft vent is parallel to side of cutout

and that mounting brackets overlap

countertop.

wn

vent

6” round ductwork system

Maximum length = 25 ft.

1 - wall

cap

= 0 feet

8 feet straight = 8 feet

2 - 90” elbows = 10 feet

Transition

= 4.5 feet

Figure 3

Built-in cabinet location

15)

’

Move support legs down against

cabinet floor. Place a level against

front of downdraft vent base and adjust until

downdraft vent is level vertically. Use a

pencil to mark the top of each leg on face of

downdraft vent. Then mark location of

support leg mounting holes on cabinet floor.

Remove downdraft vent from cutout. Drill

starter holes at each mounting screw

location on cabinet floor. Align top of legs

with pencil marks on face of downdraft vent.

Tighten screws in legs.

Length of 6” system = 22.5 feet

Figure 4

Panel C