5-1

Before testing any of the components, perform

the following checks:

• The most common cause for control failure is

corrosion on connectors. Therefore, discon-

necting and reconnecting wires will be nec-

essary throughout test procedures.

Refer to page 4-4 for the procedure for servic-

ing a thermistor.

1. Run the diagnostics tests (see page 6-1)

and test the thermistors in steps 01 and

02.

NOTE: For accurate temperature/resistance

readings, continue with the remaining steps to

check the resistance of the thermistor(s).

2. Unplug the refrigerator or disconnect the

power.

3. Disconnect the thermistor wire connector

from the main harness.

4. Set the ohmmeter to the R x 1K scale.

5. Insert the test probes into the two connec-

tor pins of the thermistor connector.

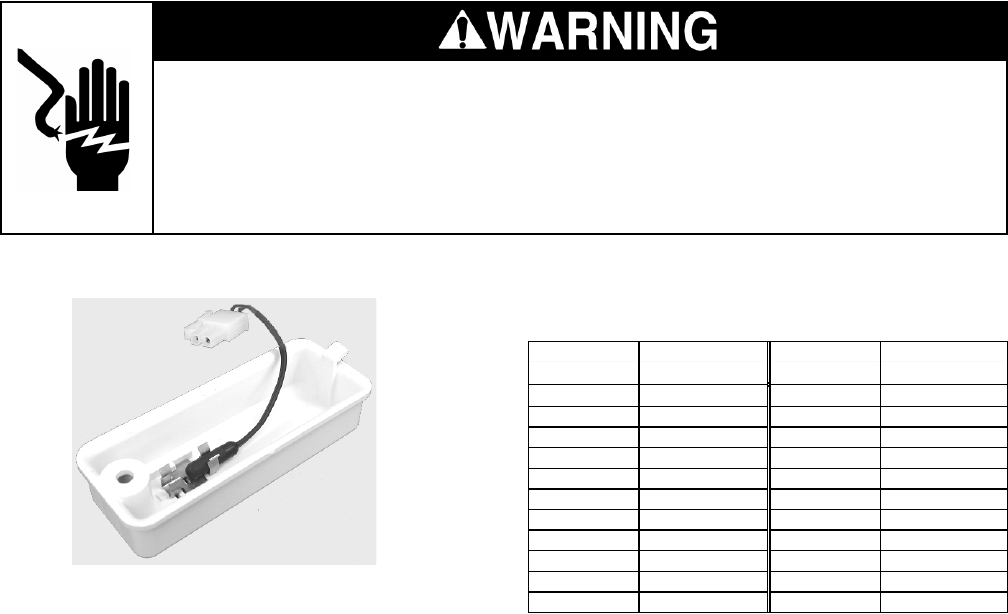

THERMISTOR

NOTE: If the resistance of the thermistor(s)

was normal, perform the following voltage test.

1. Set the voltmeter to read a maximum

voltage of 10 volts DC.

2. Connect power to the refrigerator and

allow it to enter the “cooling” mode.

3. With the thermistor disconnected and the

refrigerator in the cooling mode, touch the

voltmeter test probes to the thermistor

main harness connector pins. The meter

should indicate approximately 5 volts DC.

If the voltage was not present, check for a

thermistor output at the main control board

(see page 5-5).

6. Depending on the temperature, the meter

should indicate within the approximate

range, as shown in the chart below.

• Check all connections before replacing com-

ponents, looking for broken or loose wires,

failed terminals, or wires not pressed into

connectors far enough.

• Resistance checks must be made with power

cord unplugged from outlet, and with wiring

harness or connectors disconnected.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all panels before operating.

Failure to do so can result in death or electrical shock.

TEMPERATURE RESISTANCE TEMPERATURE RESISTANCE

(°°

°°

F)

OHMS (APPROX.)

(°°

°°

F)

OHMS (APPROX.)

–5 25900-27500 45 5930-6300

0 22100-23500 50 5190-5510

5 18900-20000 55 4550-4830

10 16200-17200 60 4000-4240

15 13900-14800 65 3520-3730

20 12000-12800 70 3100-3300

25 10400-11000 75 2740-2910

30 8990-9550 80 2430-2580

32 8750 85 2160-2290

35 7800-8290 90 1920-2030

40 6800-7220

COMPONENT TESTING