Impinger I – 1400 Series Advantage Service Manual - Dom & Int’l

14

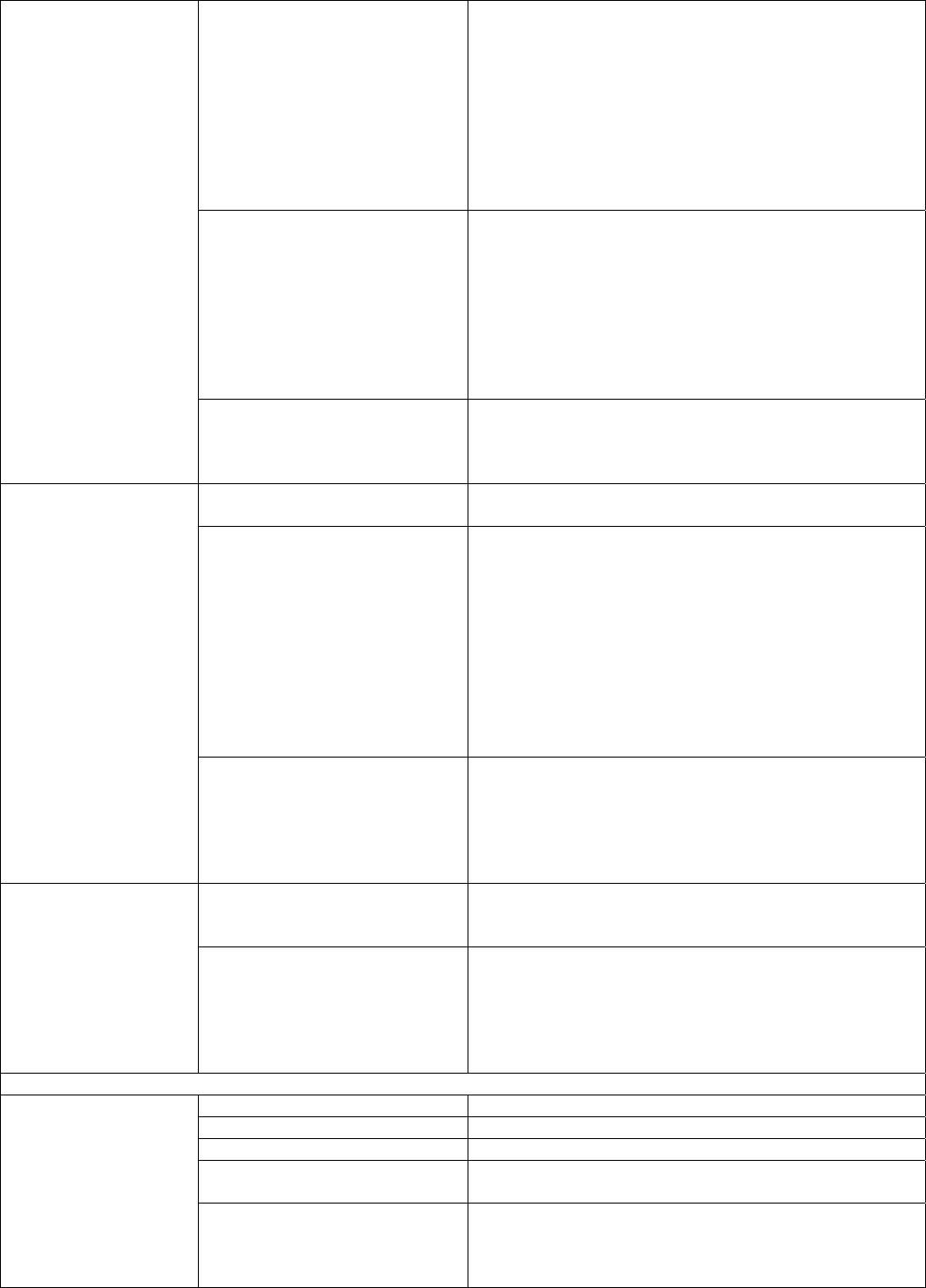

DC Motor Control Board Check for 120 VAC input to the control board at

terminals L1 and L2. If not present, check the oven

fan switch and wiring back to 3 amp fuse and then

back to power source if necessary. If 120 VAC is

present at L1 and L2, check both fuses on control

board (4A line) and (1A armature), check the VDC

output at terminals A+ and A-. If 120 VAC is present

at terminals L1 and L2, and DC voltage is present A+

and A-, but motor does not run, check gear motor as

follows.

Conveyor Gear Motor If DC voltage is present at A+ and A-and the motor

does not run, first check the mini breaker and then the

conveyor. Refer to the next possible cause. Check the

leads to the motor for evidence of any shorts or

opens, and each lead to ground. If the motor fails the

above tests, replace motor. From the top of the motor,

rotate motor shaft to determine if there is a locked

rotor or a locked gear box (use care so magnet and

the H.S. board are not damaged). Replace as needed.

Conveyor Check for any mechanical mis-alignment . Also check

for worn bearings. A conveyor belt that is over

tightened may cause excessive bearing wear and

sometimes, irregular speed.

Power Supply Check power supply at the DC control board for the

120 VAC at board terminals L1 and L2

D.C. Motor Control Board Place the test meter probes on terminals A+ and A- .

(With speed potentiometer set to maximum speed (

Approx. 2 min.) The meter reading should be

approximately 100 VDC (±3%). The board output is

steady. If the board voltage output is unsteady beyond

limits (±3%) then the board is probably bad. Always

check the speed pot. , be sure it is okay before

changing a board. This test is not always 100%

accurate as this test is not performed at operating

speeds. However, this test is the best method

currently available.

Conveyor speed

varying or intermittent

DC Gearmotor If the DC control board is steady then the problem

may be the motor or gearbox. Check the brushes in

the motor for excessive arching and/or unusual wear.

Check the motor and gearbox from instruction located

on page 14 under "possible cause" Listing "conveyor

gear motor."

Magnet Check to insure that the magnet (cemented to shaft of

conveyor drive motor) has not been damaged, or

come loose from motor shaft. Replace as needed.

Hall Effect Sensor Check for any physical damage to Hall Effect Sensor

(mounted on conveyor drive motor Check all wiring

and connections for damage. Check all connections

for tightness or proper location and check all wiring for

visible damage. Replace as needed. Connect new

Hall Effect to system and check for steady operation.

MODELS 1456 - 1457-1474-1475-1476

Gas Supply Check for adequate gas supply to oven.

Manual Gas Shut-Off Valve Check to see that manual shut-off valve is open.

Fan Switch Check to see that the fan switch is on.

Main Oven Fan Check if main oven fan is operating. If not, refer to

"Oven fan will not run."

Oven will not heat

Air Pressure Switch Check for supply voltage on both sides of switch. If

voltage present on one side only, check for air tube

blockage or misalignment, adjust air switch. Replace

as needed.