Impinger I – 1400 Series Advantage Service Manual – Dom & Int’l

5

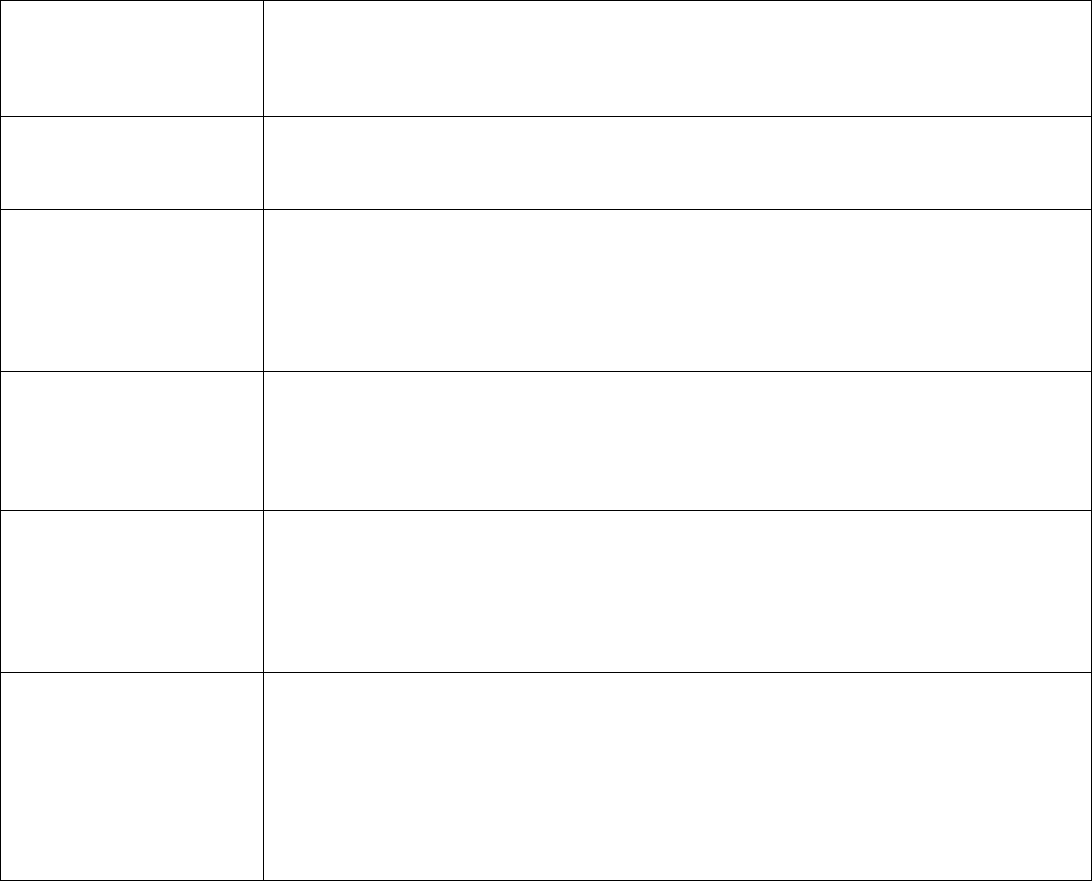

SEQUENCE OF OPERATIONS

MODEL 1456 / 220-240 VAC / 50 HZ / NATURAL GAS

MODEL 1457 / 220-240 VAC / 50 HZ / L.P. GAS

MODEL 1474 / 220-240 VAC / 50 HZ / NATURAL GAS

MODEL 1475 / 220-240 VAC / 50 HZ / L.P. GAS

MODEL 1476 / 220-240 VAC / 50 HZ / TOWN GAS

POWER SUPPLY Electrical power is to be supplied to the oven by a three-conductor service.

Brown conductor is hot.

Blue conductor is neutral.

Green conductor is ground.

CONTROL BOX AUTO

COOL DOWN

When the temperature in the control box reaches 120°F ± 3° (48.9°C ± 1.7°C), the cooling

fan thermostat will switch power to the control box cooling fan. The thermostat will interrupt

power to the cooling fan when the control box temperature falls to 100°F ± 3° (37.0°C ±

1.7° C).

MAIN FAN CIRCUIT Electrical power is permanently supplied to the normally open contacts of the double pole

main fan relay, the cooling fan thermostat and, through a 3A fuse to the normally open

double pole main fan switch. Closing the oven fan switch supplies line voltage to the

primary of the control circuit step down transformer. The transformer steps the voltage

down to 120 VAC for the control circuit. 120 VAC is supplied to the coil of the double pole

main fan relay. The coil of the relay is energized. The normally open contacts now close,

energizing the main fan motor through one 10A fuse, and the cooling fan motor.

BURNER CIRCUIT Closing the oven fan switch supplies line voltage through the main fan air pressure switch,

through the gas pressure proving switch, through the normally closed Hi-Limit Thermostat,

to the ignition control. The combustion motor is now energized The normally open

combustion air switch closes upon sensing air. After a pre-purge period of between 30 and

60 seconds, the spark generator and the main gas valve are energized. Ignition should

now occur, after proving, gas control relay is energized.

TEMPERATURE

CONTROL

Closing the oven power switch supplies 120 VAC (through the step-down transformer) to

the temperature control board. The temperature dial is adjusted to desires temperature.

The thermocouple will provide varying millivolts to the temperature controller. The

temperature controller supplies120 VAC through contact of gas control relay to the

solenoid valve at intervals to maintain desired temperature. The ready lamp is energized

with the solenoid valve (an electronic flame monitor proves main flame operation in the

1474, 1475, 1476 models.)

CONVEYOR DRIVE Closing the on/off switch supplies 120 VAC (through the step down transformer) to the

conveyor control board. AC volts are converted to DC volts and are supplied to the

conveyor motor at terminals A+ and A-. Adjustment of the speed control potentiometer will

change resistance at terminals P1 & P2 varying the DC voltage to the motor. The speed of

the conveyor motor will increase or decrease as the DC voltage from the board increases

or decreases respectively.

NOTE: The conveyor control uses a sensor and magnet, mounted on the conveyor motor

that senses the motor speed. Any change in motor load (± RPM) is detected by the sensor

and the voltage to the motor is adjusted accordingly.