Impinger X2 – Digital Service Manual – Dom & Int’l

15

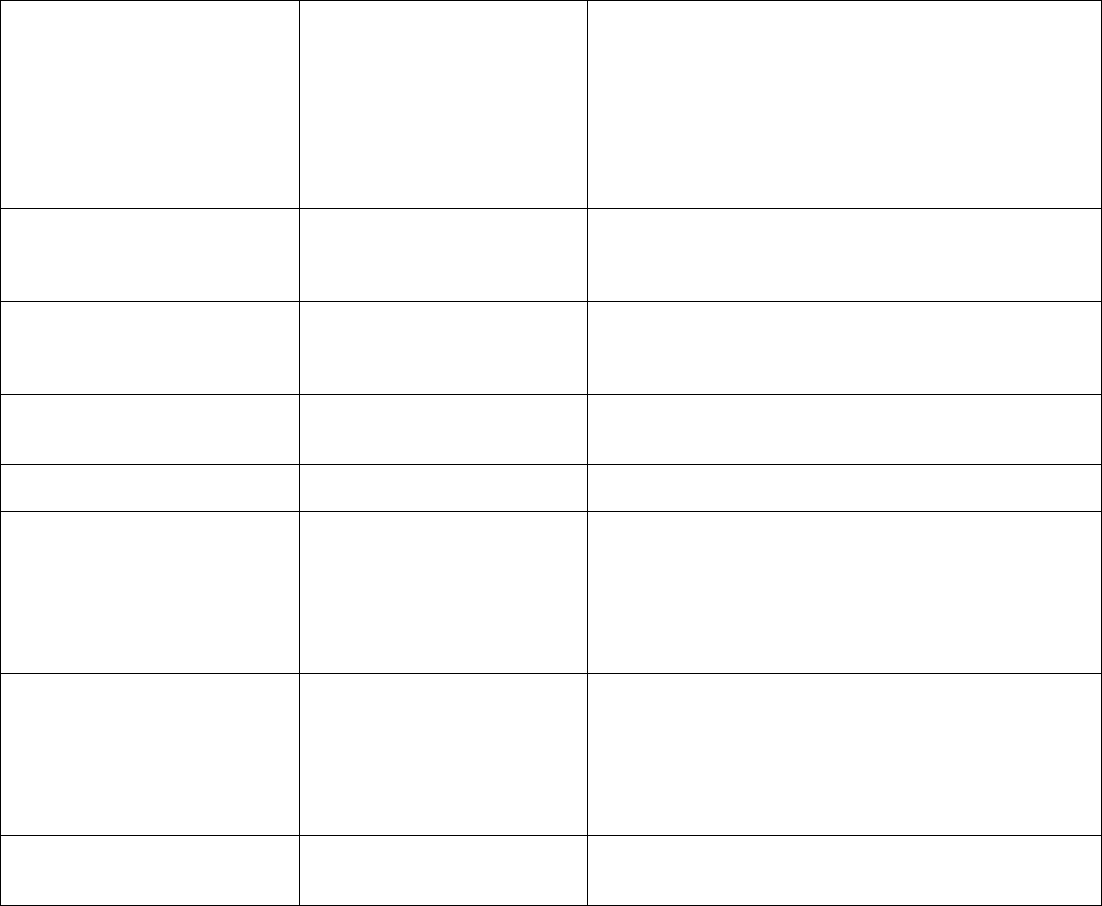

present, trace wiring back to the reversing switch. If

voltage is present, check motor windings for opens or

shorts.

WITH POWER OFF: Check the motor windings as

follows:

Grey to Black - 114 ohm approx.

Grey to Brown - 114 ohm approx.

Brown to Black - 228 ohm approx.

If any of the above fail, replace motor.

Capacitor, conveyor motor Check for shorts or grounds. Replace capacitor as

needed.

WARNING: Capacitor has a stored charge, discharge

before testing.

Conveyor Check for any mechanical problems in the conveyor

assembly. Check for damaged or torn belting. Check

conveyor shaft bearings for damage or excessive wear.

Repair or replace conveyor components as needed.

Oven control If there is voltage supplied to the motor, and the motor,

capacitor, and reversing switch check good, replace the

oven control.

Conveyor motor runs, but there

is no speed display

NOTE: Display will indicate

“STALL”

Oven control Check output voltage from oven control to hall effect

sensor (sensor is located in conveyor motor). Measure

voltage at the motor connector, red wire and yellow

wire. Voltage should be approx. 10VDC. If no voltage is

present, trace wiring back to the oven control. If there is

no voltage output present at the oven control, replace

the oven control.

Motor, conveyor If there is voltage supplied to the hall effect sensor,

check for a frequency output from the hall effect

sensor. Measure frequency across the yellow and white

wires at the motor connector. Frequency readings

should be between 15 Hz-500 Hz. If these readings are

not achieved, replace conveyor motor. If these readings

are achieved, proceed.

Oven control If the hall effect sensor readings are correct, but there

is no speed indicated on the display, replace the

control.