9

Figure #5

If locking arm fails to hook locking pin, turn cam-lock counter-clockwise one completes turn and repeat the

procedure like Figure #3

LEVEL FLOOR

It is very important that the existing floor be level If it is not level the insulated floor panels must be leveled by

shimming between the existing floor and the floor panels. Assembling a walk-in of any type on an uneven or

unleveled floor without some sort of shimming of grouting is not practical, not advisable and will never result in

a satisfactory installation.

Leveling of floor type walk-in floor panels should be accomplished by the use of a sand leveling bed or the use

of shim stock. Shim stock can be rot resistant wood, strips of galvanized sheet metal, etc. Shims under floor

panels must be no further than 18” on center in both length and width so as to property support the floor

panels when the walk-in is assembled and the product load is in place. Shimming just the outer edges of just

the corners of the floor panels will result in broken panels and/or separation of the metal liners from the foam.

CAULKING

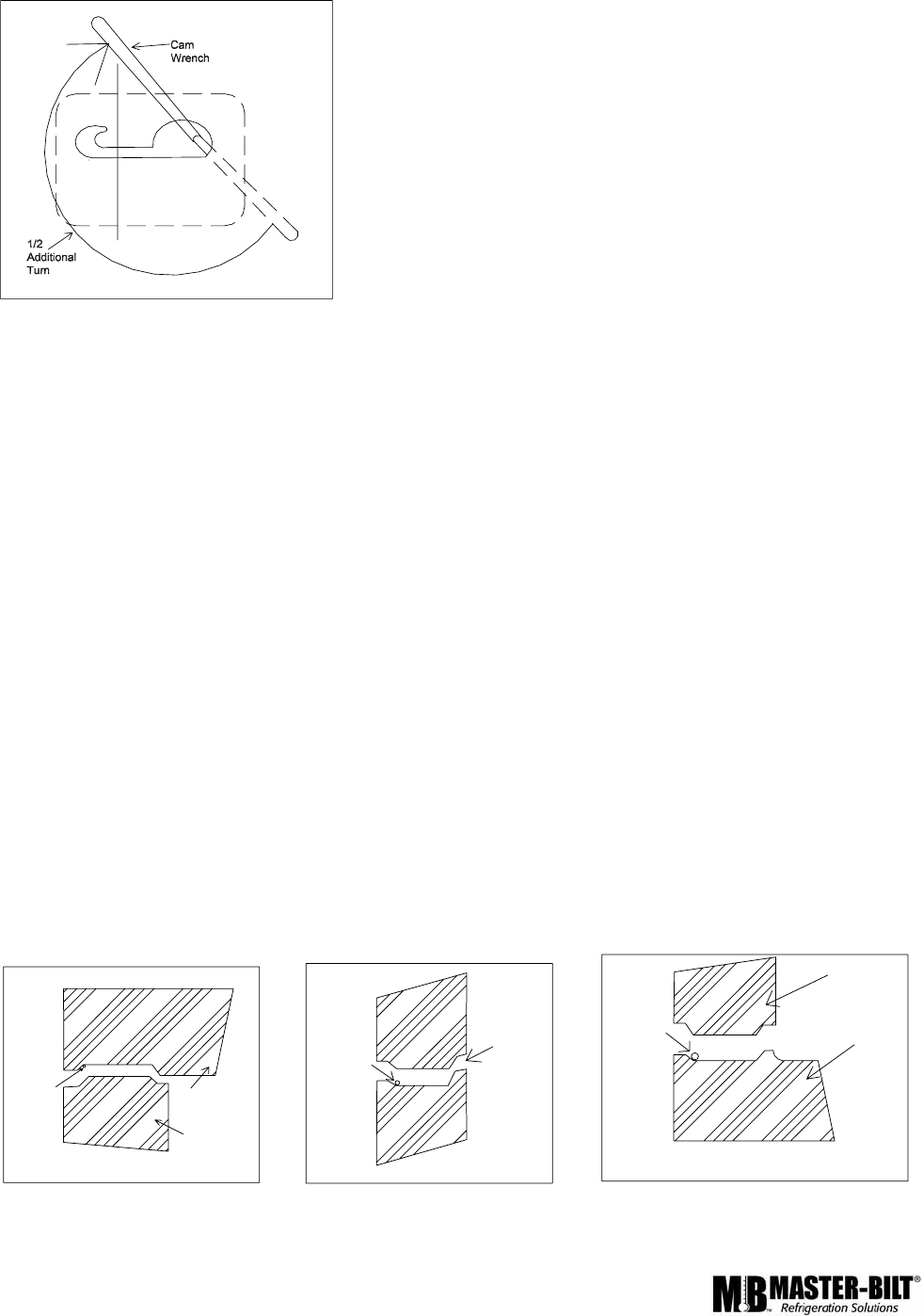

Caulking is recommended in all panel joints as shown in Figure #6, #7, and #8. Caulk should be of high-

grade outdoor type odorless compound. Approximately one tube of caulk is repaired for every 60 square feet

of panel surface.

It should be noted that on walk-ins subject to external weather conditions, the caulking of roof joints does not

seal the roof against water penetration. Therefore, a weather protective roof must be installed atop the

insulated roof panels.

Caulking

Roof

panel

wall

panel

Caulking

Joining

seam

of

like

panels

Caulking

Wall Panel

Floor Panel

Figure # 6 Figure # 7 Figure # 8

Roof to Wall Caulking Detail Like Panel To Like Panels Caulking Details Floor to Wall Caulking Detail