SECTION 2

INSTALLATION

13

WARNING

DO NOT USE CONDUIT OR GAS LINE

FOR GROUND CONNECTION.

CAUTION

IT IS RECOMMENDED THAT THE OVEN

BE PLACED UNDER A VENTILATION

HOOD FOR ADEQUATE AIR SUPPLY

AND VENTILATION.

ELECTRIC SUPPLY TO BE

PROVIDED BY CUSTOMER

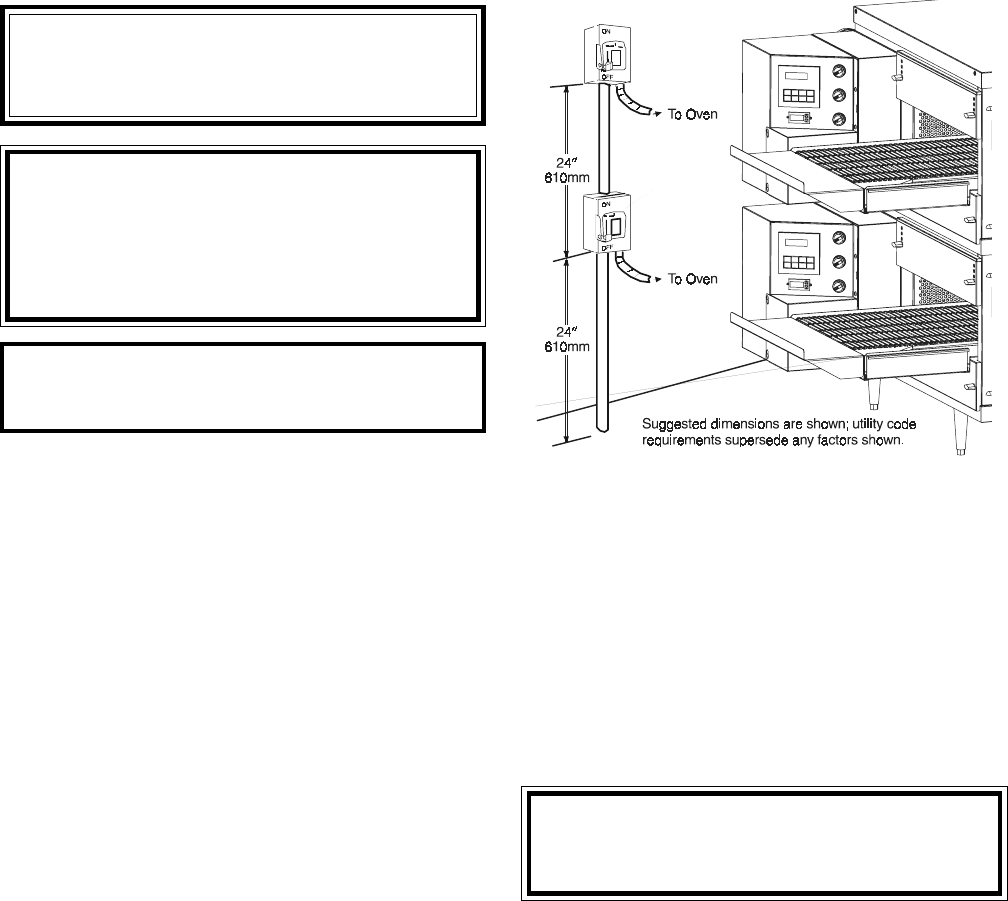

CIRCUIT BREAKER

Separate circuit breaker with lockout/tagout electrical

shutoff for each oven. Wire each oven separately.

15A Amp circuit breaker for 208-240V.

ELECTRICAL SPECIFICATIONS

DOMESTIC: 208V main blower motors, 1 Ph, 1.5 Amp

draw, 50/60 Hz, 208-240V control circuit, 2 pole, 3 wire

system per oven (2 hot, 1 grd).

Do

NOT

use conduit for ground.

or

DOMESTIC or EXPORT: 240V main blower motors, 1 Ph,

1.5 Amp draw, 50/60 Hz, 208-240V control circuit, 2 pole,

3 wire system per oven (2 hot, 1 grd).

230V main blower motors, 1 Ph, 1.5 Amp draw, 50/60 Hz,

208-240V control circuit, 2 pole, 3 wire system per oven

(2 hot, 1 grd).

Do

NOT

use conduit for ground.

UTILITY ROUGH-IN DIMENSIONS AND POSITIONING

FOR PS520-SERIES OVENS

POWER RATING

40,000 BTU/hr (11.7 kW/hr.

SUPPLY WIRE

Supply wire size must be in accordance with the National

Electrical Code (current edition) and must be in compli-

ance with local codes.

SUGGESTED

If space permits, service should be located near the

control console end of the oven(s) to allow convenient

access to safety switches.

CAUTION

UNIT MUST HAVE AIR VENT PLATES IN-

STALLED OR WARRANTY WILL BE VOID.

II. VENTILATION GUIDELINES

A mechanically driven ventilation system is required for the

PS520 Series Middleby Marshall conveyorized gas ovens.

Local codes and conditions vary greatly from one area to

another and must be complied with. Following are the

suggested requirements for good ventilation. Please re-

member these are recommendations or guidelines, you

may have a special condition or problem that will require

the services of a ventilation engineer or specialist. Proper

ventilation is the oven owner’s responsibility. Improper

ventilation can inhibit oven performance.

Please Note: There are now two “stand off”

‘C’ Channels and the “plate” for “Double

and Triple Ovens” that must be installed in

the field.

Figure 2-9. Typical PS520-Series Oven(s)

Installation