PAGE 36 — STXD6i RIDE-ON TROWEL• OPERATION MANUAL — REV. #0 (03/23/12)

TROUBLESHOOTING

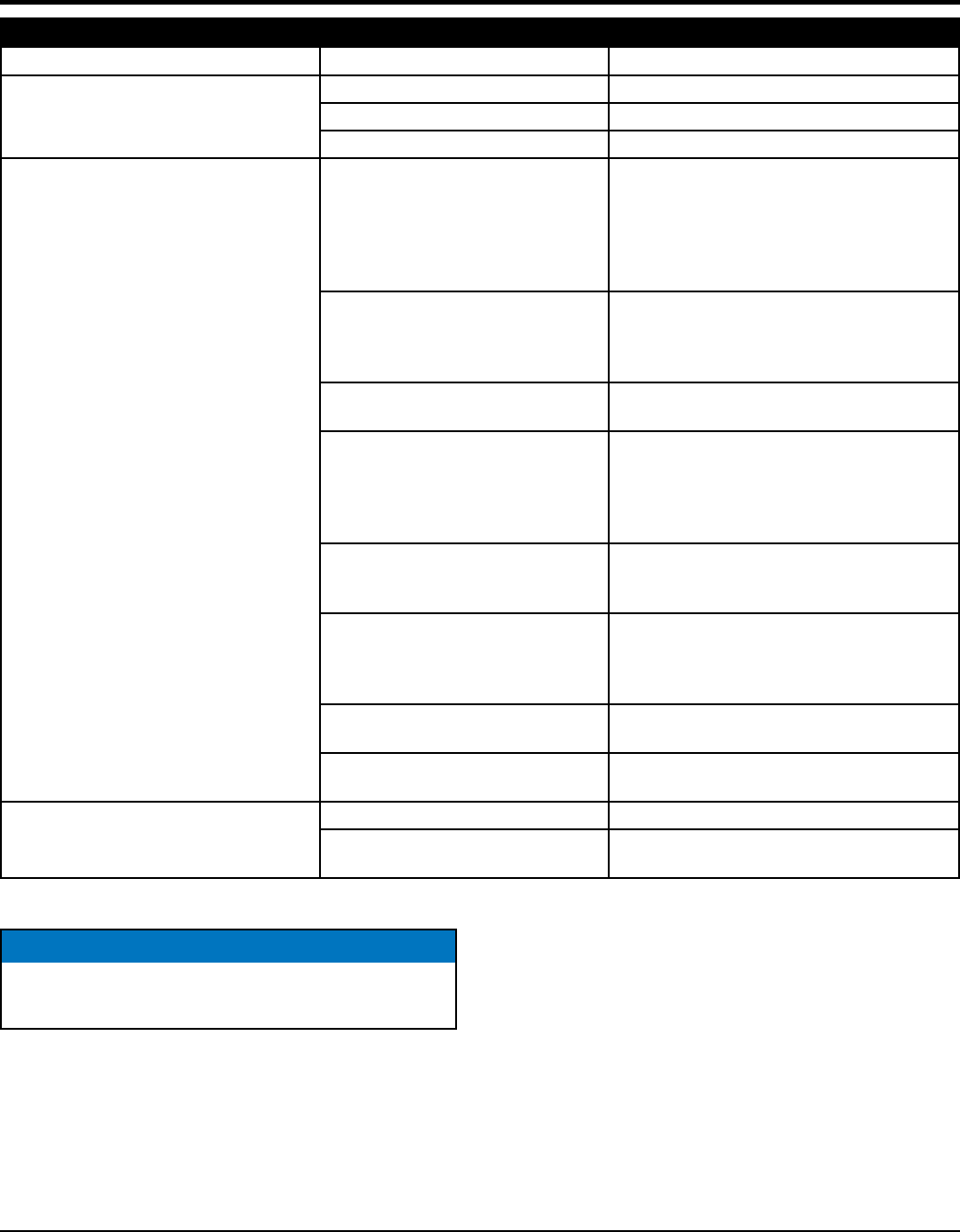

Troubleshooting (Ride-On Hydraulic Trowel)

Symptom Possible Problem Solution

Safety stop switch not functioning.

Other problems? Consult engine manufacturer’s manual.

Loose wire connections? Check wiring. Replace as necessary.

Bad contacts? Replace seat cushion (contains the switch).

If trowel “bounces, rolls concrete, or makes uneven

swirls in concrete”..

Blades?

Make certain blades are in good condition, not

excessively worn. Finish blades should measure no

less than 2"" (50mm) from the blade bar to the trailing

edge, combo blades should measure no less that 3.5""

(89mm). Trailing edge of blade should be straight and

parallel to the blade bar.

Spider?

Check that all blades are set at the same pitch angle

as measured at the spider. A fi eld adjustment tool is

available for height adjustment of the trowel arms (see

Optional Equipment)..

Bent trowel arms?

Check the spider assembly for bent trowel arms. If one

of the arms is even slightly bent, replace it immediately.

Trowel arm bushings?

Check the trowel arm bushings for tightness. This can

be done by moving the trowel arms up and down. If

there is more than 1/8"" (3.2 mm) of travel at the tip of

the arm, the bushings should be replaced. All bushings

should be replaced at the same time.

Thrust collar?

Check the fl atness of the thrust collar by rotating it on

the spider. If it varies by more than 0.02"" (0.5 mm)

replace the thrust collar.

Thrust collar bushing?

Check the thrust collar by rocking it on the spider. If it

can tilt more than 1/16"" (1.6 mm) [as measured at the

thrust collar O.D.], replace the bushing in the thrust

collar.

Thrust bearing worn?

Check the thrust bearing to see that it is spinning freely.

Replace if necessary.

Blade pitch?

Check blades for consistent pitch. Adjust per

Maintenance Section instructions if necessary.

Machine has a perceptible rolling motion while

running.

Spider Finger Screws? Adjust per procedure in Maintenance Section.

Yoke?

Check to make sure that both fi ngers of the yoke press

evenly on the wear cap. Replace yoke as necessary.

NOTICE

Refer to MQ Setup/Inspection/Test Procedures Manual

for Troubleshooting Details.