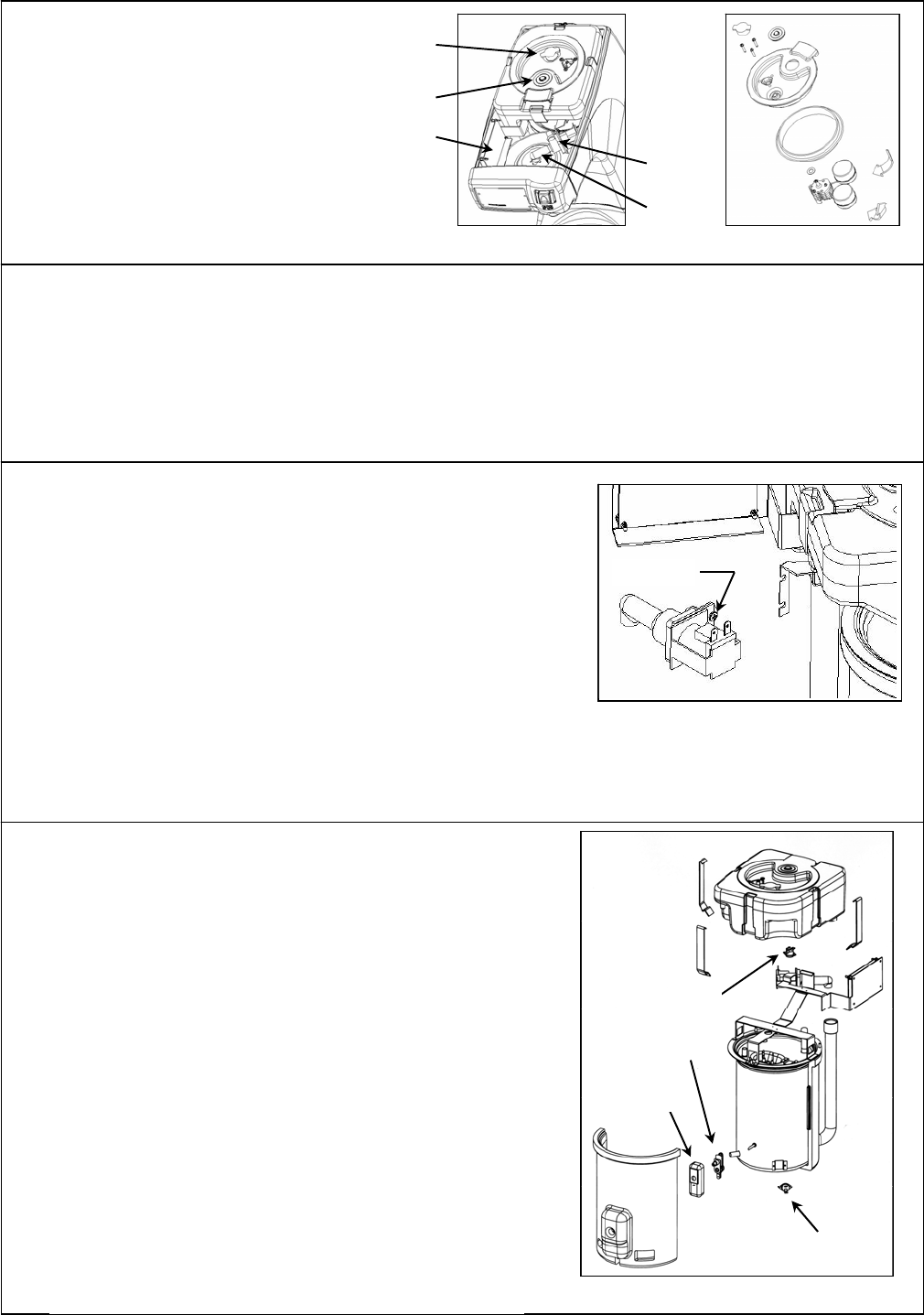

D. SERVICING THE MECHANICAL FLOATS

Resetting the Safety Float

1. Remove cover from cabinet.

2. Press down on the safety float

re-set button (see figure 8).

Float arm inspection

1. Remove float cap from top

reservoir.

2. Float arms should move up and

down freely and should not bind

or catch (see figure 9).

E. INSPECT AND REPLACE CIRCUIT BOARD FUSE

1. Disconnect power cord from electrical outlet.

2. Remove cover from cabinet.

3. Locate fuse at the lower right side of the circuit board (see

figure 8) and inspect the fuse filament for breakage.

4. If fuse appears to have blown, carefully remove it from the

circuit board and check it for continuity.

5. If fuse is blown, replace it with a 25 volt, 5 AMP, slow blow

fuse.

F. INSPECT AND REPLACE DUMP SOLENOID VALVE

1. Disconnect power cord from electrical outlet.

2. Remove cover from cabinet.

3. Locate dump solenoid (see figure 8) and visually inspect clear

solenoid valve body for mineral build up or debris.

4. If build up or obstruction has occurred, remove the hot tank assembly

from the outer cabinet (see section C).

5. Remove both sets of wires from the solenoid valve.

6. Remove from the solenoid valve both the silicone tube from the hot

tank and the angled silicone tube going to the spray head.

7. Remove the dump solenoid by loosening the two screws that hold it to

the bracket assembly. Once the screws have been loosened, the

solenoid valve can be removed from the bracket slots (see figure 10).

8. If replacement is required, assemble a new or refurbished dump

solenoid valve in the reverse order.

G. THERMOSTAT REPLACEMENT

Primary Thermostat (see figure11)

1. Disconnect the power cord from both the electrical outlet

and the IEC plug located at the rear of the brewer (see

figure 5).

2. Remove the hot tank assembly from the outer cabinet (see

section C).

3. Remove both wires from the anti boil thermostat.

4. Loosen tie wire and remove the rear half of the insulation

from the hot tank.

5. Using an 11/32

inch nut driver, remove nut from thermostat

threaded weld stud. Nut secures thermostat and cover.

6. Remove thermostat cover.

7. Remove thermostat from threaded weld stud.

8. Remove both wires from thermostat.

9. Replace using the reverse order as above.

NOTE: When threading the nut back to the weld stud (the

reverse of step 5) a torque value of 18 inch pounds must be

applied for proper assembly.

A

nt

i

-Boil Thermostat (see figure 11)

1. Follow steps (1-4) from Primary Thermostat.

2. Using a ¼ inch nut driver remove both screws from bracket.

3. Replace using the reverse order.

Figure 9

Mechanical Float Cap Assembly

Figure 10

Dump Solenoid Valve

Loosen Solenoid

Screws (2)

Limite

r

Control

Primar

y

Thermostat

Primary Thermostat

Cove

r

A

nti-Boil

Thermostat

Figure 11

Thermostat Locations

Figure 8

Open Cover

Safety float

re-set button

Air filte

r

Circuit Board

Solenoid

Valve

Spray Head

Tube