6

1. The first step in pressure canning is to assemble the can-

ning equipment. Be sure your canner is thoroughly cleaned

and working properly. Before each canning season, check

the dial gauge for accuracy (see page 8, step 11). Also check

the sealing ring, overpressure plug, and the rubber gasket

of the air vent/cover lock. Replace these parts when they

become hard, deformed, cracked, worn, pitted, or unusually

soft (see page 8, step 13).

2. Check Mason jars for nicks, cracks, and sharp edges.

Check screw bands for dents or rust. Use only jars, lids,

and bands in perfect condition so an airtight seal may be

obtained.

Wash and rinse jars, lids, and bands. Pour hot water into jars

and set aside until needed. Follow closure manufacturer’s

directions for bands and lids.

3. Select fresh firm food. Sort food according to size. Clean

food thoroughly. Prepare according to recipe. Fill hot Mason

jars promptly with food and liquid to recommended level. Allow

½-inch headspace for fruits. ALL vegetables and meats require

1-inch headspace due to expansion during processing.

Work out air bubbles with a clean nonmetallic spatula. Wipe

sealing edge clean with a damp cloth.

Adjust bands according to closure manufacturer’s direc-

tions.

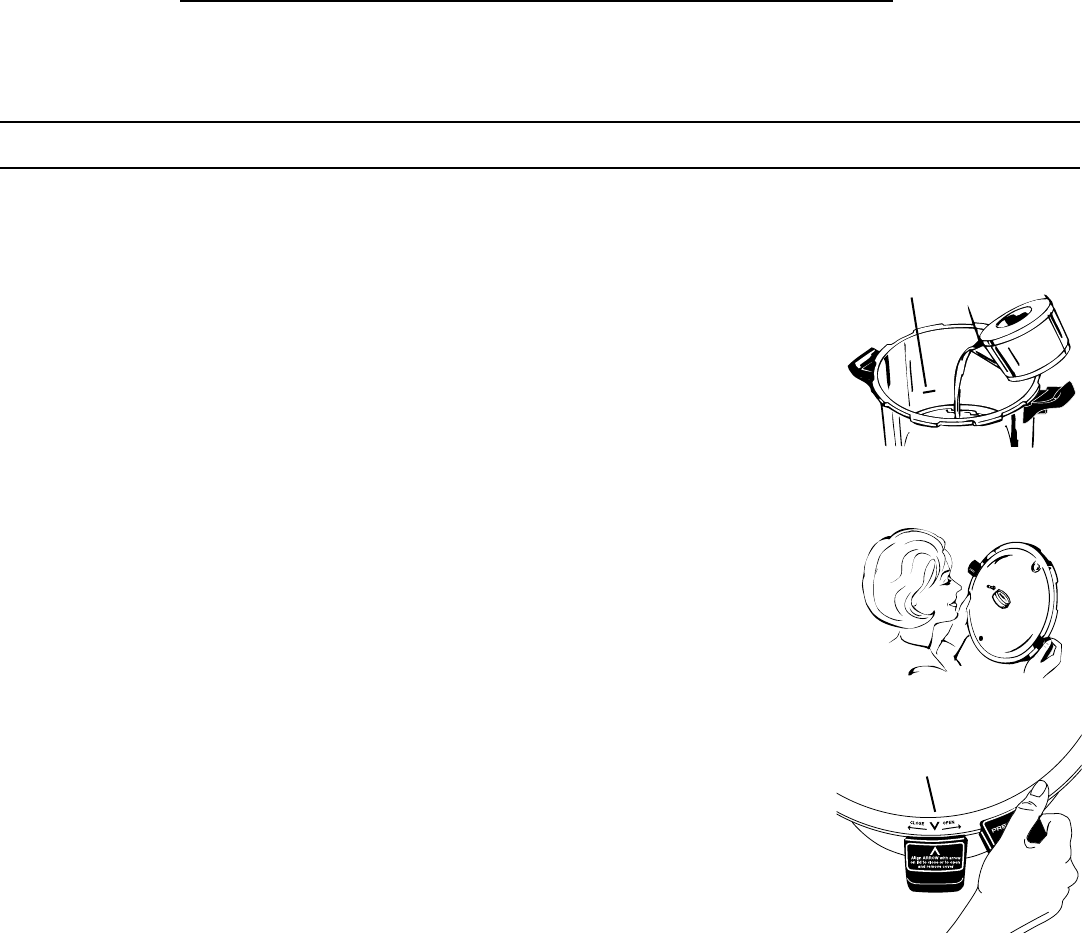

4. P l a c e 3 q u a r t s o f

boiling water, canning

rack, and jars in canner.

To prevent water stains

on jars, add 2 tablespoons

white vinegar to water in

canner. Always use canning

rack. Jars may break if

set directly on bottom of

canner.

5. Look through the vent

pipe to be certain it is open

before placing cover on

canner. To clean the vent

pipe, draw a pipe cleaner

or small brush through the

opening.

6. Place cover on can-

ner, aligning the V mark on

the cover with the

V

mark

on the body handle and

lock securely by turning in

the direction indicated to

close (clockwise). Cover

handles must be centered

over body handles. Do not

force beyond this posi-

tion.

As a safeguard against using canned foods which may be affected with spoilage that is not readily detected, boil all low acid foods

and tomatoes for 10 minutes at altitudes below 1,000 feet. Extend the boiling time by 1 minute for each 1,000 foot increase in

altitude.

Many times odors that cannot be detected in the cold product will become evident by these methods. If, after boiling, food does

not smell or look right, discard it without tasting.

MASON JARS: While there are many styles and shapes of glass jars on the market, only Mason jars are recommended for home

canning. Mason jars are available in ½ pint, pint, and quart capacities with threads on which a cap may be screwed. See the chart

below for the jar capacity of your canner. Additional information may be obtained from the manufacturers of Mason jars.

CLOSURES FOR MASON JARS: The two-piece vacuum cap consists of a flat metal lid held in place with a screw band. A rubber

compound on the underside of the lid forms a seal during processing. Follow the closure manufacturer’s directions for using the

two-piece cap and for testing for a proper seal. If the closure has not sealed, completely reprocess or use the food immediately.

Refer to the closure manufacturer’s directions for additional information.

CANNER JAR CAPACITIES FOR PRESSURE CANNING

(MAXIMUM CAPACITY)

MODEL NO. beginning with ½ PINT 1 PINT 1 QUART

0175 12 10 7

0178 24 20 7

Please note: To double deck pint and half pint jars, see page 19.

How To PRessuRe Can foods

IMPORTANT: Read carefully. Do not attempt to use your canner before reading these instructions.

Follow these step-by-step instructions for pressure canning in your canner. Prepare food according to the directions in specific

recipe.

3-quart water line

Align the V mark on the

cover with the

V

mark on

the body handle.