Instructions for the installer

60

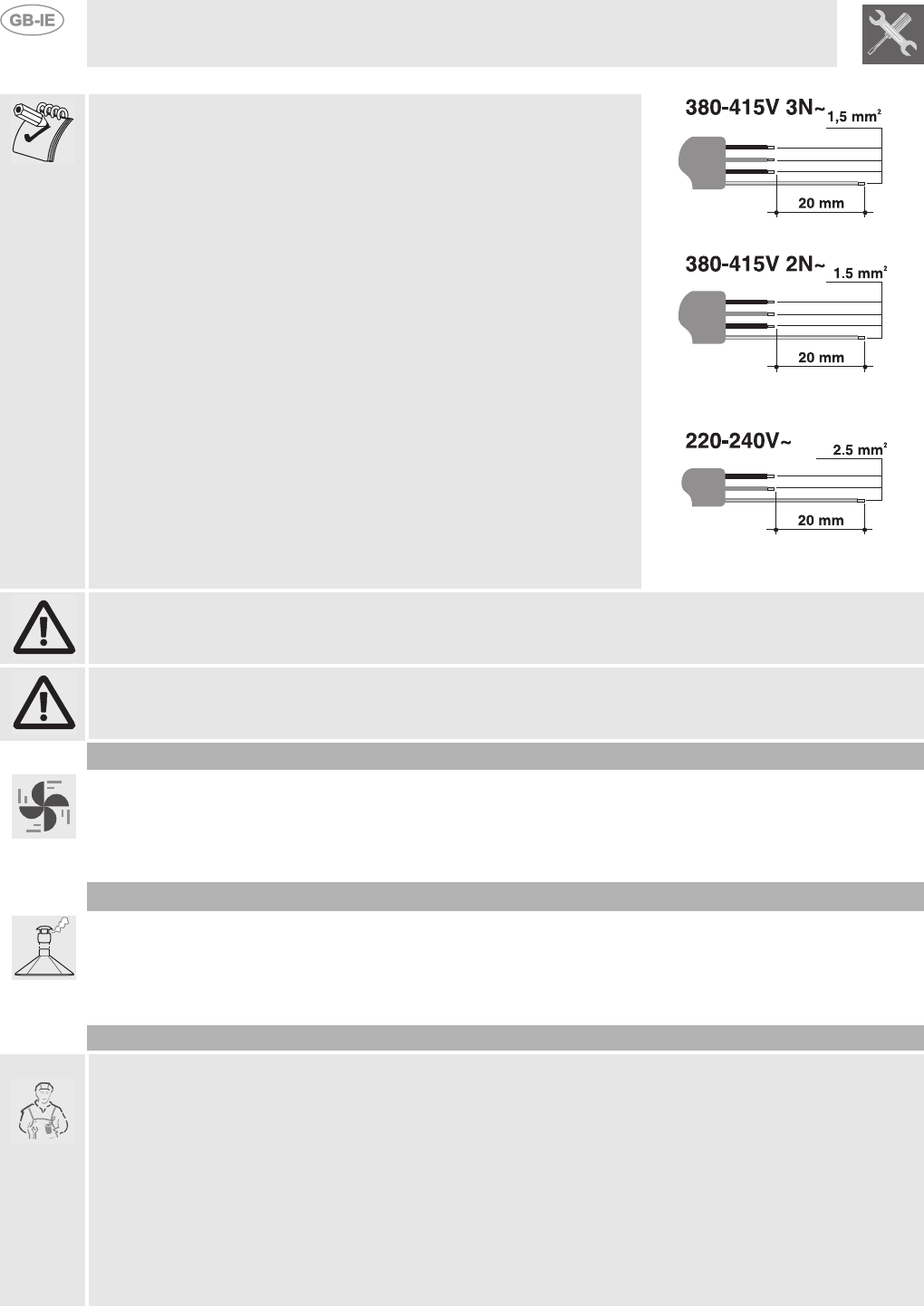

For operation on 380-415V 3N~: use an H05V2V2-F type five-core

cable (5 x 1.5 mm

2

).

For operation on 380-415V 2N~: use an H05V2V2-F type four-core

cable (4 x 1.5 mm

2

).

For operation on 220-240V~: use an H05V2V2-F type three-core

cable (3 x 2.5 mm

2

).

The earth wire (yellow-green) must be at least 20 mm longer than

the other wires at the end for connection to the appliance.

WARNING: The values indicated above refer to the cross-section of the internal conductor.

THE MANUFACTURER DECLINES ALL RESPONSIBILITY FOR DAMAGE TO PERSONS OR THINGS

CAUSED BY NON-OBSERVANCE OF THE ABOVE PRESCRIPTIONS.

16.2 Ventilation requirements

The room containing the appliance should have an air supply in accordance with the standards in force.

The room where the appliance is installed must have enough air flow as required for the regular

combustion of gas and by the necessary air exchange of the same room. The air vent, protected by

grills, must be suitably dimensioned in compliance with the current regulations and positioned so that no

part of it is obstructed.

16.3 Extraction of the products of combustion

Extraction of the products of combustion must be ensured by means of hoods connected to a natural

draught chimney whose efficiency is assured or via forced extraction. An efficient extraction system

requires precision planning by a specialist qualified in this area and must comply with the positions and

distances indicated by the regulations. When the job is complete, the installer must issue a certificate of

conformity.

16.4 Connection to gas

Installation of the UNI-CIG 7140 compliant rubber hose must be carried out so that

the hose length is no greater than 1.5 metres. Make sure that the hose does not

come into contact with moving parts or is squashed. The inside diameter of the hose must be 8 mm for

LPG.

LIQUID and 13 mm for METHANE GAS and TOWN GAS.

Verify that all the follow conditions are met:

• the hose is fixed to the hose connection with safety clamps;

• no part of the hose is in contact with the hot walls (max. 50 °C);

• the hose is not under traction or tension and has no tight curves or twists;

• the hose is not in contact with sharp objects or sharp corners;

• if the hose is not perfectly airtight and leaks gas, do not try and repair it: replace it with a new hose;

• verify that the hose is not beyond its life cycle (serigraphed on the hose itself).