Recold

/

JW Series Fluid Cooler

/

Engineering Data

5

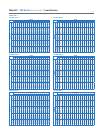

Model

Fan Motor

hp*

Air Volume

cfm

Fan

RPM

Standard Fan

Motor Frame

Pump Motor

hp

Spray Water

GPM

Sump Heater

kW

Approximate Weight lb

shipping operating

JW10A 2 5280 689 145T

1

⁄2 40 2.0 910 1400

JW10B 2 5150 706 145T

1

⁄2 40 2.0 955 1400

JW10C 3 5450 825 182T

1

⁄2 40 2.0 1005 1500

JW15B 5 8500 729 184T

1

⁄2 50 2.0 1365 2000

JW15C 5 8300 740 184T

1

⁄2 50 2.0 1435 2400

JW25A 5 11700 500 184T

3

⁄4 70 4.0 1850 2800

JW25B 5 11800 523 184T

3

⁄4 70 4.0 1955 2900

JW25C 7

1

⁄2 13000 614 213T

3

⁄4 70 4.0 2075 3200

JW35A 7

1

⁄2 19000 413 213T 1 110 4.0 2955 4300

JW35B 10 20000 462 215T 1 110 4.0 3140 4600

JW35C 10 19500 476 215T 1 110 4.0 3305 5000

JW50A 15 30200 385 254T 2 150 6.0 4380 6700

JW50B 15 29200 397 254T 2 150 6.0 4635 7200

JW50C 15 28400 385 254T 2 150 6.0 4885 7600

JW70B 20 37200 385 256T 3 250 8.0 6685 10200

JW70C 25 39000 415 284T 3 250 8.0 7085 10900

JW85B 30 52300 415 286T 3 325 11.0 7725 11900

JW85C 30 50000 430 286T 3 325 11.0 8185 12900

JW100B 30 58300 270 286T 5 375 11.0 9170 16870

JW100C 30 61000 280 286T 5 365 11.0 9675 17775

JW115B 40 66000 280 324T 5 400 14.0 10080 19050

JW115C 40 69000 290 324T 5 400 14.0 10670 20170

JW130B 50 76500 300 326T 5 450 16.0 11025 21425

JW130C 50 80000 305 326T 5 450 16.0 11720 22620

* For static pressure from

1

⁄4 to

1

⁄2 ESP use next size larger motor

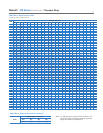

Model

JWL

Sump Capacity

gal

JW

Coil Volume

gal

JWH

Coil Face Area

sq ft

Circuits Connection OD Circuits Connection OD Circuits Connection OD

JW10A 10 2

@

2

5

⁄8" 43 21 2

@

2

5

⁄8" 16 — — 9.7

JW10B 21 2

@

2

5

⁄8" 43 42 2

@

2

5

⁄8" 20 — — 9.7

JW10C 21 2

@

2

5

⁄8" 43 42 2

@

2

5

⁄8" 24 — — 9.7

JW15B 26 2

@

3

1

⁄8" 64 52 2

@

3

1

⁄8" 31 — — 14.5

JW15C 26 2

@

3

1

⁄8" 64 52 2

@

3

1

⁄8" 37 — — 14.5

JW25A 33 2

@

3

1

⁄8" 95 66 2

@

3

1

⁄8" 37 — — 21.6

JW25B 33 2

@

3

1

⁄8" 95 66 2

@

3

1

⁄8" 47 — — 21.6

JW25C 33 2

@

3

1

⁄8" 95 66 2

@

3

1

⁄8" 57 — — 21.6

JW35A 41 2

@

3

1

⁄8" 163 82 2

@

3

1

⁄8" 54 — — 32.5

JW35B 41 2

@

3

1

⁄8" 163 82 2

@

3

1

⁄8" 70 164 4

@

3

1

⁄8" 32.5

JW35C 41 2

@

3

1

⁄8" 163 82 2

@

3

1

⁄8" 86 205 4

@

3

1

⁄8" 32.5

JW50A 50 2

@

3

1

⁄8" 248 100 2

@

3

1

⁄8" 82 — — 49.6

JW50B 50 2

@

3

1

⁄8" 248 100 2

@

3

1

⁄8" 106 200 4

@

3

1

⁄8" 49.6

JW50C 50 2

@

3

1

⁄8" 248 100 2

@

3

1

⁄8" 130 250 4

@

3

1

⁄8" 49.6

JW70B 70 4

@

3

1

⁄8" 374 140 4

@

3

1

⁄8" 146 280 8

@

3

1

⁄8" 70.4

JW70C 70 4

@

3

1

⁄8" 374 140 4

@

3

1

⁄8" 182 350 8

@

3

1

⁄8" 70.4

JW85B 70 4

@

3

1

⁄8" 454 140 4

@

3

1

⁄8" 177 280 8

@

3

1

⁄8" 85.5

JW85C 70 4

@

3

1

⁄8" 454 140 4

@

3

1

⁄8" 200 350 8

@

3

1

⁄8" 85.5

JW100B 76 4

@

3

1

⁄8" 748 152 4

@

3

1

⁄8" 212 304 8

@

3

1

⁄8" 92.5

JW100C 76 4

@

3

1

⁄8" 748 152 4

@

3

1

⁄8" 262 380 8

@

3

1

⁄8" 92.5

JW115B 76 4

@

3

1

⁄8" 880 152 4

@

3

1

⁄8" 247 304 8

@

3

1

⁄8" 108.9

JW115C 76 4

@

3

1

⁄8" 880 152 4

@

3

1

⁄8" 305 380 8

@

3

1

⁄8" 108.9

JW130B 76 4

@

3

1

⁄8" 1012 152 4

@

3

1

⁄8" 305 304 8

@

3

1

⁄8" 125.2

JW130C 76 4

@

3

1

⁄8" 1012 152 4

@

3

1

⁄8" 349 380 8

@

3

1

⁄8" 125.2

Note

Inlet and outlet connection sizes shown are standard

copper OD and are sized for nominal flow rates. Actual

sizes should be specified to conform to job requirements.

If special connections are required, such as flanges or

threaded fittings, consult your Recold sales representative.

Connection quantity is total of in and out connections