Recold

/

JW Series Fluid Cooler

/

Selection Procedure

7

Closed circuit cooler selections can easily be made by using the information on pages 6 through 11. The

examples below demonstrate proper procedures for water and ethylene glycol solutions. Other fluids can be

cooled, but since their heat transfer and flow characteristics may vary, please contact your local Recold sales

representative for assistance.

WATER SELECTION EXAMPLE

Select a unit to cool 225 GPM of water from 102°F to

90°F at 76°F wet bulb temperature.

1. Determine Range:

102°F - 90°F = 12°F Range

2. Determine Approach:

90°F - 76°F = 14°F Approach

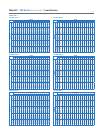

3. Select Load Factor — Enter Unit Load Factor Table 2

for 76°F wet bulb. Select load factor based on

12°F range and 14°F approach. Load factor in this

example equals 3.3. When wet bulb temperature

is an odd number interpolate between appropriate

tables to determine the load factor.

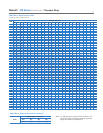

4. Select Unit Model — Table 3, the load factor

determined in step 3 falls between 3.0 and 3.5.

Enter the 3.0 column and read down to the smallest

unit flow rating which is greater than or equal to

225 GPM. For the Model JWL35B, interpolate

between 245 and 190 GPM to determine the

flow rating at the 3.3 load factor. Interpolation

gives a rating of 212 GPM which is less than the

design requirement. Select a Model JWL35C and

again interpolate between load factor columns

to determine flow rating. The second selection

provides a flow rating of 245 GPM which exceeds

the design requirement. The correct unit size is,

therefore, a Model 35C

5. Determine Flow Limitations — Enter Table 3 at unit

size determined in Step 4 to select a JWL low flow

or JW standard flow unit. The Model 35C with 225

GPM design flow falls within the standard coil flow

limitations. The correct unit selection is, therefore,

a JW35C.

6. Determine Coil Pressure Drop — Enter the Coil

Pressure Drop Table at 225 GPM and read across

to the unit model column to select pressure drop

reading. In this example, pressure drop equals

4.8 PSI.

ETHYLENE GLYCOL EXAMPLE

Select a unit to cool 75 GPM of 40% by volume

ethylene glycol from 107°F to 85°F with 78°F wet

bulb.

1. Determine Range:

107°F - 85°F = 22°F Range

2. Determine Approach:

85°F - 78°F = 7°F Approach

3. Select Load Factor — Enter Table 2 for 78°F wet bulb

and select load factor at design range and approach.

Select 6.0 factor.

4. Select Test Unit Model — Enter the Unit Rating

Table 3 at the 6.0 load factor and read down to the

smallest unit flow rating greater than or equal to the

design 75 GPM. Select the test model JWL35C

5. Correct Flow for Ethylene Glycol — The flow correction

factor obtained from Table 1 is 1.04. 75 GPM x 1.04

= 78 GPM

6. Adjust Model Selection — Re-enter Table 3 at the 6.0

load factor and make selection based on corrected

flow of 78 GPM. The adjusted unit selection is the

Model JWL50A indicating an 80 GPM rating

7. Determine Flow Limitations — Enter Table 3 at unit

size determined in Step 6 to select a JWL low flow

or JW standard flow unit. The Model 50A with

75 GPM design flow falls within the low flow coil

limitations. The correct unit selection is, therefore,

a JWL50A.

8. Determine Coil Pressure Drop — For ethylene glycol

pressure drop calculation, the conversion factor

from Table 5 must be applied to design flow before

entering Table 4. 75 GPM x 1.05 = 79 GPM.

The coil pressure drop for 79 GPM is 2.4 PSI

DEFINITIONS

Range: the difference between the entering and

leaving water temperatures (WT in – WT out).

Approach: the difference between the leaving water

temperature and the web bulb temperature (WT out

– WB).

Load BTUH =

GPM x 500 x Sp. Gr. x Sp. Ht. x (T

1

– T

2

) where

Sp. Gr. = specific gravity at average temperature

Sp. Ht. = specific heat at average temperature

T

1

= entering temperature

T

2

= leaving temperature