11

TROUBLESHOOTING GUIDE

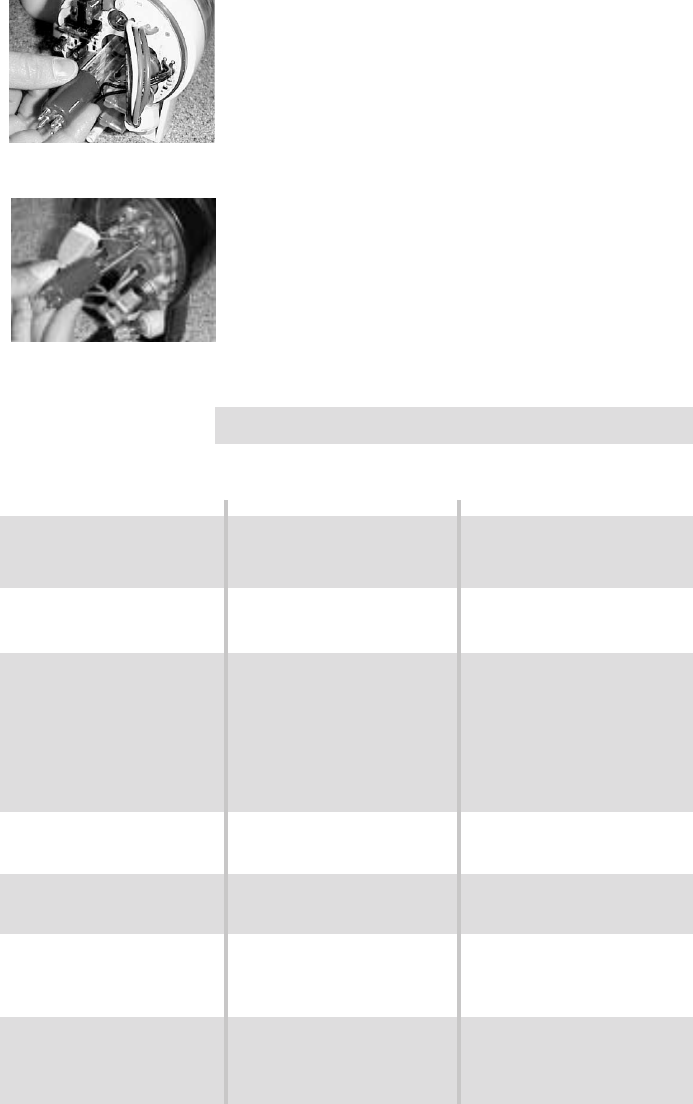

5. Loosen the lamp retention screw (External

Power supply units–Figure 26).

6. Slide the lamp out carefully

(Figures 26 and 27).

7. Insert the new lamp in the sleeve and

reinstall the lamp.

8. Reinstall lamp wiring and the bottom cover.

9. Reinstall the lter as provided in the lter

replacement instructions (see page 7).

10. Reconnect power.

The unit is now ready for operation.

Unit leaking at tubing

connection(s) after unit has been

serviced.

Unit leaks around top cap after

lter has been replaced.

Water is owing from the unit at a

very slow rate.

Lamp does not light when unit is

operated.

No bubbles are visible in the

incoming stream.

After removing unit for service,

no bubbles are visible in unit

when running.

Unit is mounted above counter

with diverted valve assembly

attached to the sink and partially

drains when not in use.

Tubing not securely connected

and/or tubing lock ring not

secured over tubing tting.

O-ring on top is not properly

seated.

Filter element plugged.

Diverter screen plugged.

Inlet plugged.

No power.

Lamp burned out.

Filter is exhausted.

Inlet and oulet tubing has been

reversed, causing reverse ow

through the unit.

Diverted valve not fully closing

when water is turned off.

Verify that tubing is properly

connected and that the lock ring

is engaged.

Verify O-ring is seated.

Replace lter.

Remove diverter valve from the

faucet and clean the screen.

Reverse ow to unit temporarily

to remove blockage. This can

be done by temporarily reversing

inlet and outlet ttings.

Make sure power is available.

Replace lamp.

Replace Filter.

Reverse tubing connections.

Push diverted valve in when unit

is not in use.

SYMPTOM POSSIBLE CAUSE POSSIBLE SOLUTION

Figure 26 (Internal Power Supply)

Removing lamp

Figure 27 (External Power Supply)

Removing lamp