14

With proper daily use of STERA-SHEEN or its equivalent,

there is no need for the use of a DELIMER.

DO NOT USE BLEACH

• BLEACH HAS ABSOLUTELY NO CLEANING

PROPERTIES.

• BLEACH IS CORROSIVE. It can and will damage

components of the machine causing premature

wear and metal corrosion.

GENERAL PURPOSE CLEANERS

General purpose cleaners do not have the ability to re-

move milkstone. Milkstone will become a problem if not

remedied with additional products and procedures.

THE USE OF CHLORINE TEST STRIPS

“Test strips” are used to determine concentrations of

active chlorine in sanitizing solutions. To use the strips,

tear off a small portion and submerge it into the sanitizing

solution. Then, compare the color change to the color key

on the side of the test strip dispenser to determine the

approximate chlorine concentration.

The ideal concentration of chlorine needs to be 100 ppm

(as stated by the FDA).

NOTE

Follow the directions on the container for proper con-

centration.

There are two main factors that contribute to falling chlo-

rine concentrations in a sanitizing solution.

1. PRODUCT USE – As the chlorine in the solution

is being used, chlorine concentrations fall.

2. TIME – As time passes, small amounts of chlorine

“evaporate” from the solution. (That is why you

can smell it.)

Sanitizing solutions should not be allowed to fall below 100

ppm chlorine. New solutions should be mixed once old

solutions become ineffective

B. DAILY

1. The exterior should be kept clean at all times to

preserve the luster of the stainless steel. A mild

alkaline cleaner is recommended. Use a soft cloth

or sponge to apply the cleaner.

C. WEEKLY

1. Check o-rings and rear seal for excessive wear

and replace if necessary.

2. Remove the drip tray by gently lifting up to

disengage from the support and pulling out. Clean

behind the drip tray and front of the freezer with a

soap solution.

D. QUARTERLY

Air Cooled

The air-cooled condenser is a copper tube and aluminum

fin type. Condensing is totally dependent upon airflow. A

plugged condenser filter, condenser, or restrictions in the

louvered panel will restrict airflow. This will lower the

capacity of the system and damage the compressor.

The condenser must be kept clean of dirt and grease. The

F112 must have a minimum of 6” (15.2 cm) of ventilation

on the right and left sides of the unit for free flow of air. The

E112 must have 3” (7.6 cm) of ventilation. Make sure the

freezer is not pulling over 100° F (37° C) air from other

equipment in the area.

The condenser and condenser filter require periodic clean-

ing. To clean, refer to the following procedures.

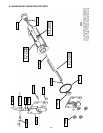

E112 Air Cooled Condenser Cleaning

A. Unscrew the knob located on the underside of the

freezer towards the front (Fig. 3-10).

B. Remove the filter bracket and remove the filter.

C. Visually inspect the condenser filter for dirt.

D. If the filter is dirty, vacuum or brush clean, rinse

with clean water and allow to dry before replacing

on the freezer.

NOTE

If the condenser is not kept clean, refrigeration effi-

ciency will be lost.

Figure 3-10 E112 Condenser Filter Removal