8

BUILT-IN INSTALLATION INSTRUCTIONS

ANTI-TIP BRACKET

INSTALLATION

IMPORTANT NOTE:

Placement of the anti-tip

brackets is critical to a stable installation. Failure

to properly position theanti-tip brackets will

prevent them from engagingthe unit.

Back Grille

Screw

Front Grille Screw

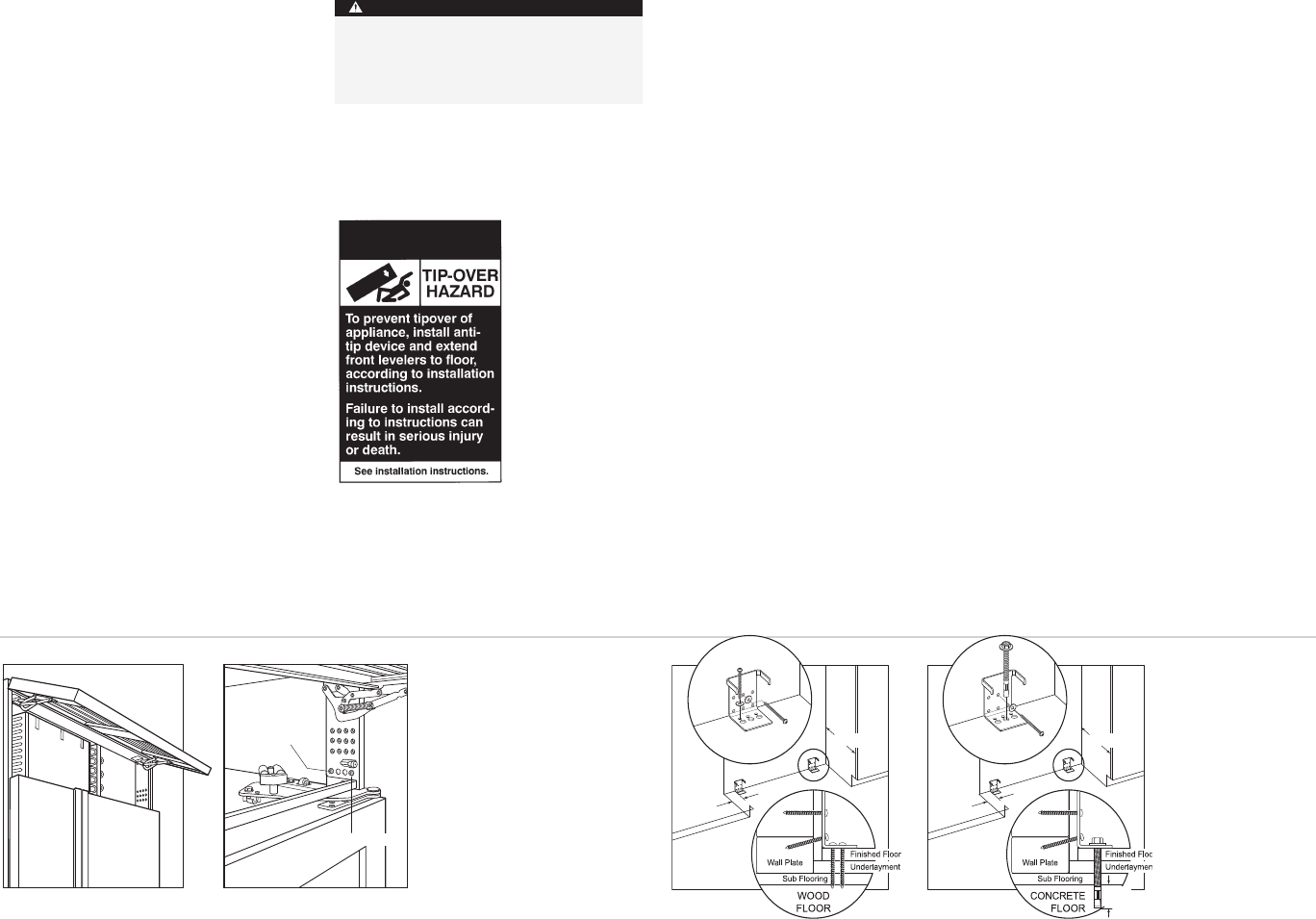

Grilleremoval

Grillemounting screws

GRILLE REMOVAL

In order to prevent damage to the grille and to

a

ccess the power cord, the top grille assembly

should be removed prior to movingthe unit.

To remove the grille assembly, pull out on the

bottom edge of the grille and tilt it upward.

Loosen the back two grille mounting screws and

r

emove the front two grille mounting screws.

With the grille heldfirmly, pullforward to

r

emove. Refer to the illustrations below.

To reinstall the grille,insert thegrille into

position and be sure that the grillecatch tabs are

engaged. Reinstall the front two grille screws,

then retighten the back two grille screws. Check

for proper fit.

Wood floors

The twoanti-tip brackets must be installed

e

xactly 610 mm from the front of the rough

opening to the back of the brackets and a

minimum of 102 mm from the sides of the rough

opening. This depth will increase to 665 mm for

a flush inset installation based on 19 mm deep

decorativepanels. Proper placement will ensure

that the anti-tip brackets engage the anti-tip bar

at the back of the unit.

IMPORTANT NOTE:

Both anti-tip brackets

MUST be used.

WOOD FLOOR APPLICATIONS

After properly locating the anti-tip brackets in the

rough opening, drill pilotholes 5 mm diameter

maximum in the wall studsand/or wall plate.

Use the #12 x 64 mm PH pan HD zinc screws and

#12 flat washers to secure the brackets in place.

Be sure that the screws penetrate through the

flooring material and into wall studs or wall plate

a minimum of 19 mm. Refer to the illustration

below.

CONCRETE FLOOR APPLICATIONS

A

fter properly locating the anti-tip brackets in the

rough opening, drill pilotholes 5 mm diameter

m

aximum in the wall studs and/or wall plate.

Then drill 10 mm diameterholes intothe

concrete a minimum of 13 mm deep. Use the

#12 x 64 mm PH pan HD zinc screws and #12 flat

washers to secure the bracketstothe wall and

u

se the10mm–16 x 95 mm wedge anchors to

secure the brackets to the floor. Be sure that the

screws penetrate the wall studs or wall plate a

minimum of 19 mm. Refer to the illustration

below.

IMPORTANT NOTE:

For either woodor concrete

floor applications, if the #12 x 64mm screws do

not hita wall stud or the wall plate in any of the

back holes of thebrackets, use the provided

#8–18 x 32mm PH truss HD screws and#12 flat

washers with the nylon zip-it wall anchors.

IMPORTANT NOTE:

In some installations the

subflooring or finished floormay necessitate

angling the screws used to fasten the anti-tip

brackets to the back wall.

102 mm

MIN

610 mm

13 mm

MIN

Concrete floors

102 mm

MIN

610 mm

ACCESSORIES

Optional acces-

soriesare available

through your

Sub-Zero dealer. To

obtainlocal dealer

information,visit

our website,

subzero.com.

To preventthe unitfrom tipping forward and

provide a stableinstallation,the unitmust be

secured in placewith the anti-tip brackets

shipped with the unit.

WARNING