20

Models 150, 152, 162, 168Operating Procedures

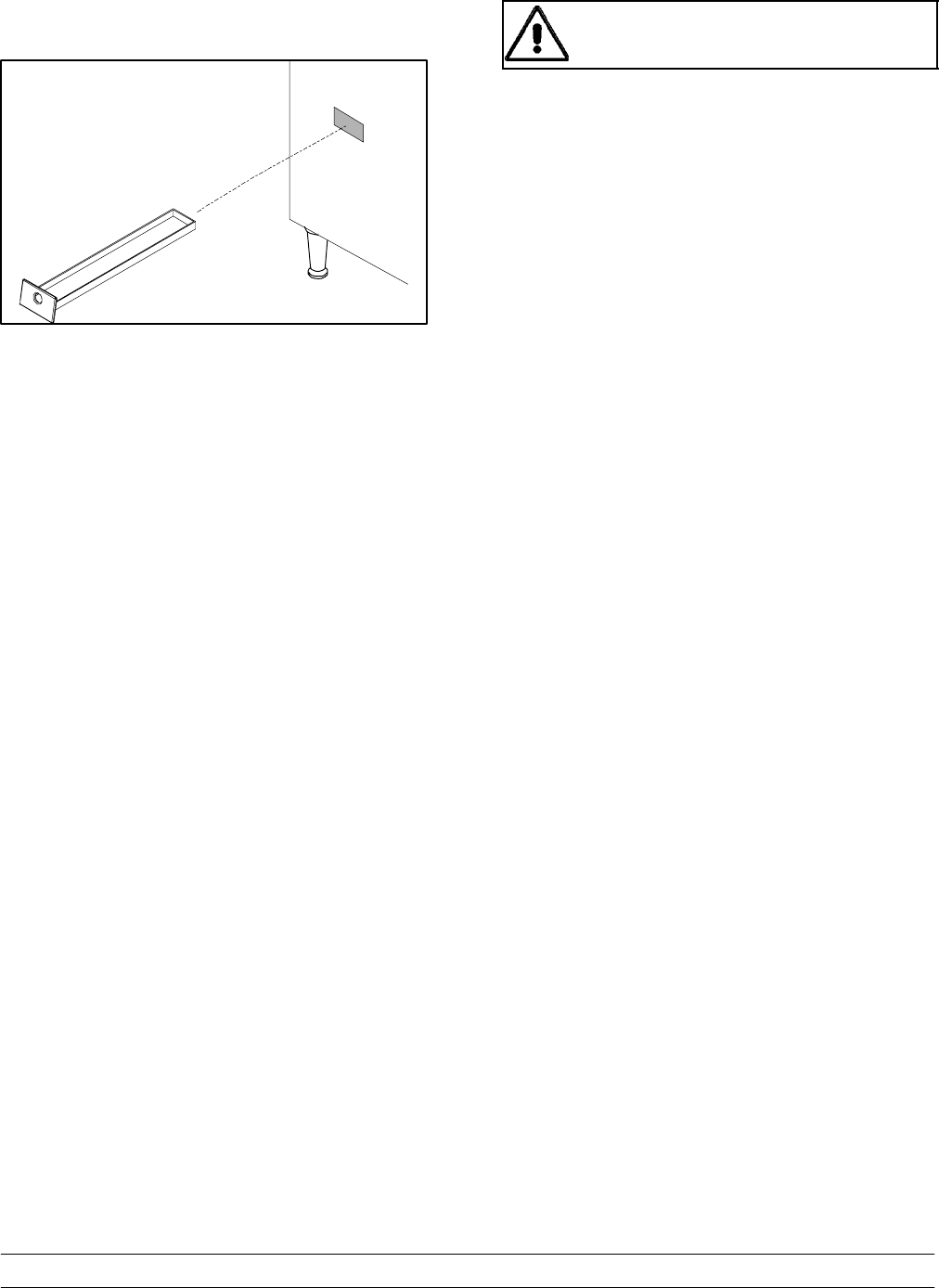

Step 6

Slide the rear drip pan into the hole in the side panel.

Figure 33

Closing Procedure

To disassemble the Models 150/152/162/168, the

following items will be needed:

S T wo cleaning pails

S Sanitized stainless steel rerun c an with lid

S Necessary brushes (provided with freezer)

S Cleaner

S Single service towels

Draining Product From the

Freezing Cylinder

Step 1

Place the power switch in the “OFF” position as far

ahead of cleaning time as possible. This will allow

frozen product to soften for easier cleaning.

Step 2

Lift the hopper cover. Remove the air tube and mix

level float. Take them to the sink for c leaning.

Step 3

With a sanitized pail beneath the door spout, place the

power switch in the “WASH” position and raise the

draw valve. When all the product stops flowing from

the door spout, lower the draw valve and place the

power switch in the “OFF” position. If local health

codes permit, empty the rerun into a sanitized

stainless steel r erun can. Cover the container and

place it in the walk-in cooler.

ALWAYS FOLLOW LOCAL HEALTH CODES.

Repeat Steps 1 through 3 for the second freezing

cylinder on Models 162/168.

Rinsing

Step 1

Pour one gallon (3.8 liters) of cool, clean water into the

mix hopper. With the brushes provided, scrub the mix

hopper, the mix level float stem and the mix inlet hole.

Step 2

With a pail beneath the door spout, place the power

switch in the “WASH” position and raise the draw

valve. Drain all the rinse water from the freezing

cylinder. When the rinse water stops flowing from the

door spout, lower the draw valve and place the power

switch in the “OFF” position.

Repeat this procedure until the rinse water being

drawn from the freezing cylinder is clear.

Repeat Steps 1 and 2 for the second freezing cylinder

on Models 162/168.

Cleaning

Step 1

Prepare one gallon (3.8 liters) of an approved cleaning

solution (example: Kay-5t). USE WARM WATER

AND FOLLOW THE MANUFACTURER’S SPECIFI-

CATIONS.

Step 2

Pour the one gallon (3.8 liters) of cleaning solution into

the mix hopper and allow it to flow into the freezing

cylinder.

Step 3

While the solution is flowing into the freezing cylinder ,

brush-clean the mix hopper, mix level float stem and

mix inlet hole.

Step 4

Place the power switch in the “WASH” position. This

will cause the cleaning solution in the freezing cylinder

to agitate.

Step 5

Place an empty pail beneath the door spout and raise

the draw valve. Draw off all the cleaning s olution.